Technology of heat treatment for controlling performace matching of complex phase fibre enhancing copper silver alloy

A technology for strengthening copper and silver alloys, applied in the field of heat treatment of copper-based alloys, can solve the problems of lack of electrical conductivity, inability to obtain a reasonable matching relationship between strength and electrical conductivity, and inability to use strength, etc., to achieve easy implementation, low degree of deformation, The effect of reducing alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The purity of 99.95% and 99.90% of Ag and electrolytic Cu are mixed in the proportion of 12% Ag, pickled and thoroughly cleaned, and then dried. First, the electrolytic Cu is placed in a vacuum induction furnace and melted under an atmospheric pressure of less than 0.1Pa After standing for degassing at 1100~1200℃, the furnace is filled with Ar to 40~50kPa and then pure Ag is added and melted. After electromagnetic stirring and standing, it is poured into a rod-shaped casting billet of specific diameter for 2~3min. The ingot mold adopts a cast iron mold, a copper mold or a water-cooled mold with good cooling conditions.

[0032] After the blank is homogenized at 720℃ / 4h, the surface is turned to remove the defects, and then deformed by the following steps: 7 passes of cold drawing to the degree of deformation η=1.3→400℃ / 1h annealing → 5 passes of cold drawing to η= 2.0→380℃ / 1h annealing→5 pass cold drawing to η=2.8→360℃ / 1h annealing→10 pass cold drawing to η=5.1.

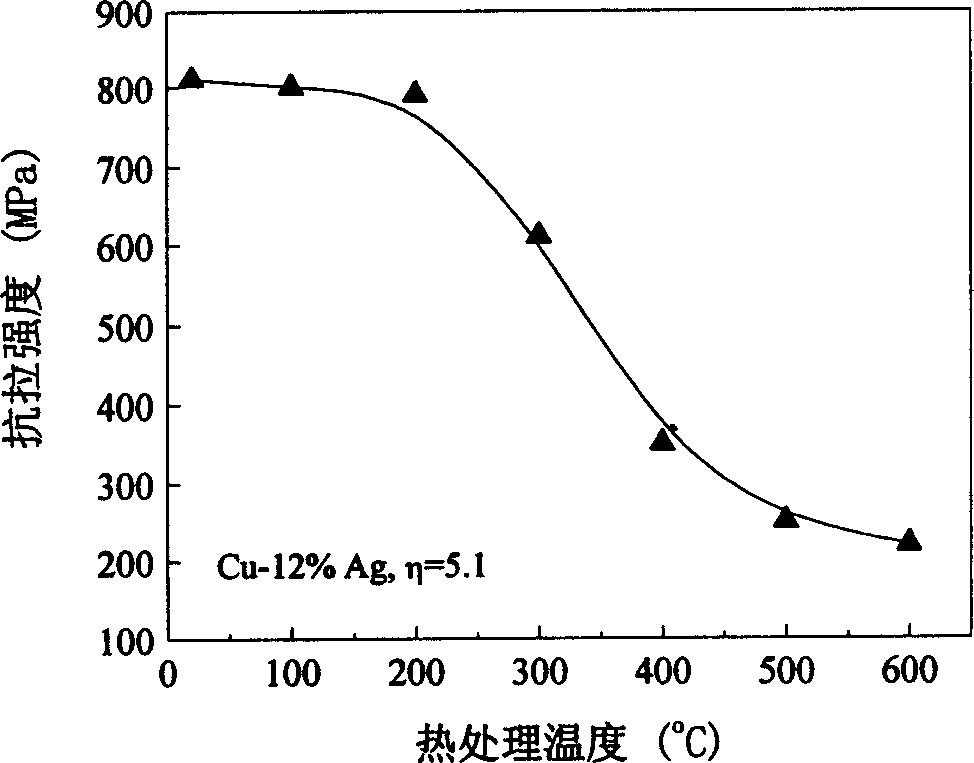

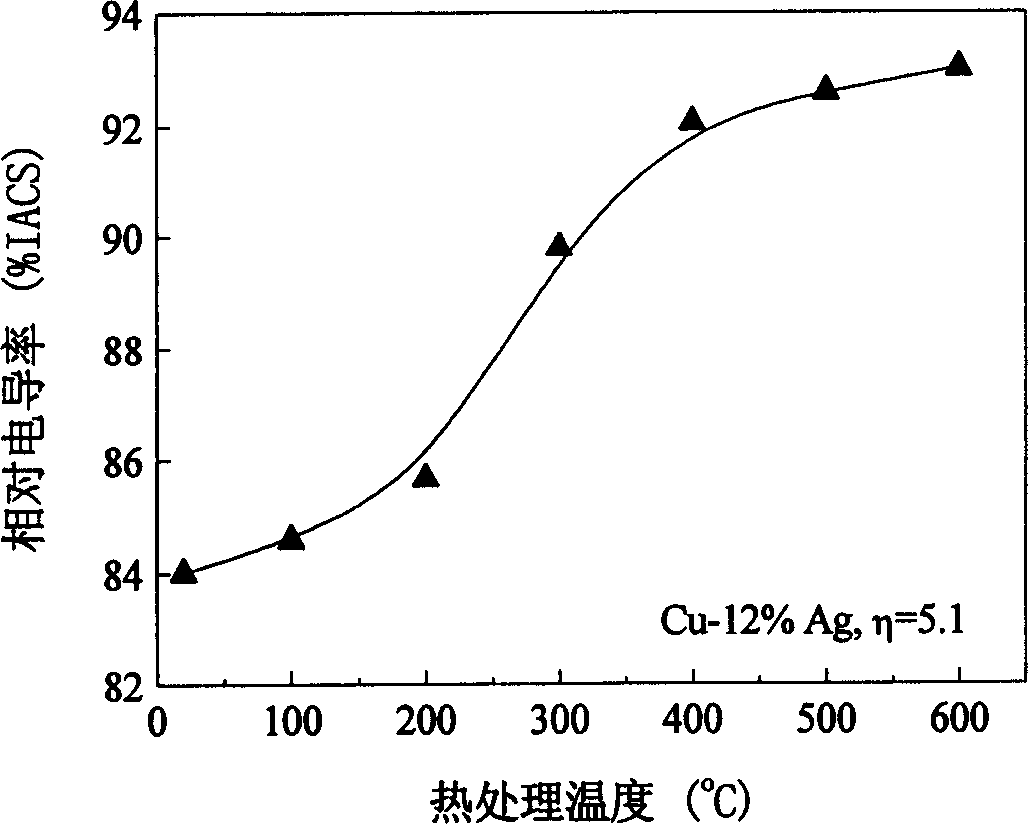

[0033] Af...

Embodiment 2

[0037] Prepare the alloy wire cold drawn to η=5.1 according to the processing method of Example 1, and then process the wire to η=7.0 and reduce the diameter to 0.6mm after 10 passes of cold drawing. Figure 4 The fiber-reinforced phase distribution pattern shown corresponds to the initial state tensile strength of 1040MPa, and the relative conductivity is 73%IACS.

[0038] The alloy wires with this initial performance level are divided into 7 batches, and each batch of samples is heat treated at different temperatures according to the heat treatment method of Example 1. After the heat treatment is completed, the alloy wire is tested for tensile and resistivity, and the relationship between the tensile strength and the heat treatment temperature is as follows: Figure 5 As shown, the tensile strength can be adjusted between 1040~300MPa; the relative conductivity changes with the heat treatment temperature as Figure 6 As shown, the relative conductivity can be adjusted between 73% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com