New technique of prepositive replenishment treatment of denitrification denitrfication for preoclating water in two-stage mineralization garbage

A treatment process and mineralized waste technology, which is applied in the new process field of mineralized landfill leachate recharge treatment, can solve the problems of low removal rate of total nitrogen in effluent, failure of effluent ammonia nitrogen to meet the standard, high project cost and operating cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

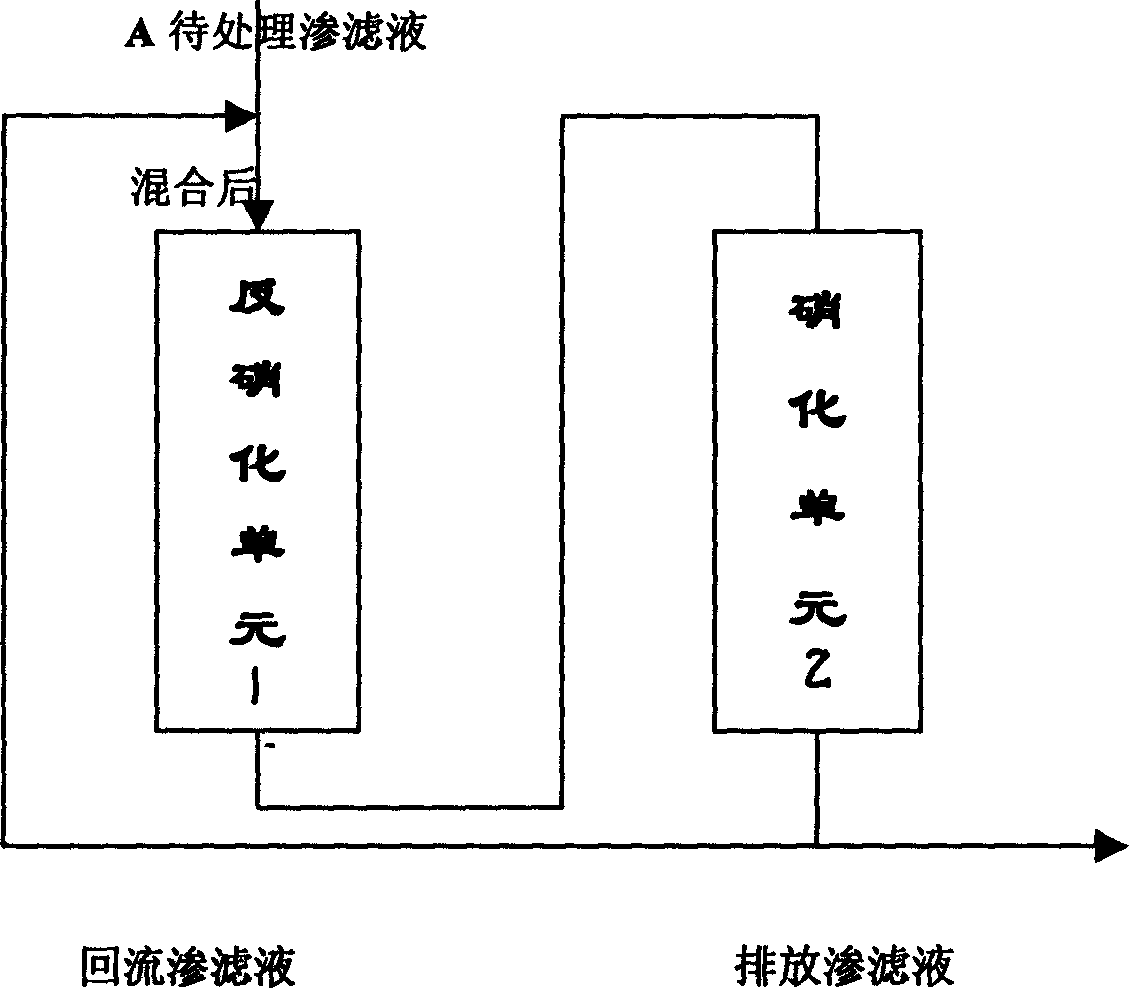

Method used

Image

Examples

Embodiment Construction

[0012] Two cast iron columns with a diameter of 0.4m and a height of 1.3m are used as denitrification and nitrification units, and the denitrification and nitrification environments in different columns are maintained by controlling the air intake. The treated leachate comes from the adjustment pond of Shanghai Laogang Landfill.

[0013] The influent hydraulic load (leachate to be treated) of the denitrification unit is 0.02m 3 / m 2 · d, the reflux ratio is 130%. The hydraulic load of the return leachate of the nitrification unit is 0.03m 3 / m 2 ·d, the reflux ratio of effluent is 50-200%. The influent and effluent quality are as follows:

[0014] Water quality of leachate before and after treatment (except pH in mg / L)

[0015] Water quality indicator COD Cr BOD 5 TN NH 3 -N NO 3 -N pH

[0016] Influent concentration 11000~15000 4600~6000 1340~1770 1200~1650 <15 7.0~8.0

[0017] Effluent concentration 280~350 15~35 180~245 <...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com