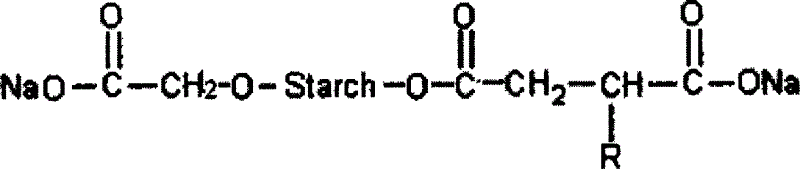

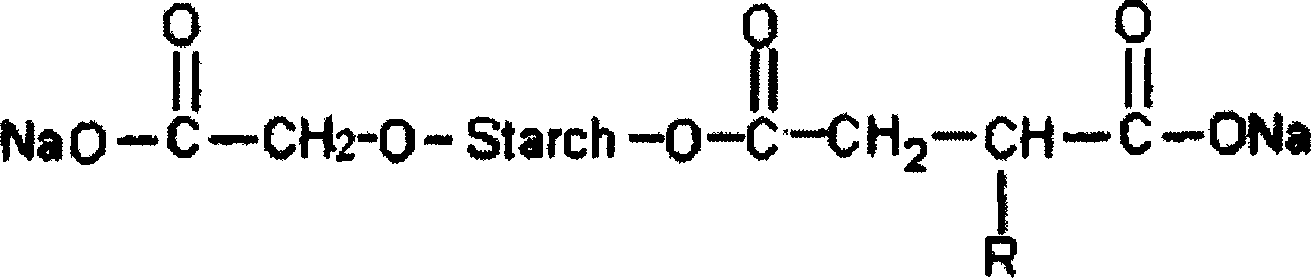

Double modified starch and preparation method

A starch and modification technology, which is applied in the field of double-modified starch and its production, can solve the problems of limited application and inconvenient commercial application, and achieve the effects of improving application performance, improving cold water solubility, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add starch and water to the reaction tank to make a starch slurry with a mass ratio concentration of 30%, keep stirring and control the temperature of the starch slurry at 30°C, adjust the pH value of the starch milk to 8 with NaOH, and add starch to the starch milk 1% alkenyl succinic anhydride by mass, while using alkali to control the pH of the system at 7.5; after reacting for 1 hour, adjust the pH to 6 with acid, filter, wash twice with water, centrifuge, and dehydrate to obtain wet alkenyl succinic acid Starch ester; adding concentration is 90% ethanol in the reaction tank, the alkenyl succinic acid starch ester that will make is added in the reaction tank, is transferred into the starch slurry that mass ratio concentration is 25%, under stirring, adding concentration is 40% % NaOH, adjust the pH value of the starch slurry at 10, stir and heat up to 40°C, alkalinize for 0.5h, then add chloroacetic acid with 50% starch mass, keep the slurry temperature at 55°C under...

Embodiment 2

[0022] Add starch and water in the reaction tank, adjust the mass ratio concentration to be 45% starch slurry, keep stirring and control the temperature of the starch slurry at 45 ° C, use Na 2 CO 2 Adjust the pH value of the starch milk to 9, add alkenyl succinic anhydride of 5% starch mass to the starch milk, and control the pH value of the system at 9 with alkali; after reacting for 2 hours, adjust the pH value to 6.5 with acid, filter, and wash with water After 3 times, centrifuge and dehydrate the wet alkenyl succinic acid starch ester; adding concentration is 95% ethanol in the reaction tank, the alkenyl succinic acid starch ester will be added in the reaction tank, adjusted to a mass ratio concentration of 40% starch slurry, under stirring, add NaOH with a concentration of 40%, adjust the pH value of the starch slurry at 12, stir and heat up to 45°C, alkalize for 1 hour, then add chloroacetic acid with 65% of the starch mass, and keep the slurry under stirring The temp...

Embodiment 3

[0024] Add starch and water to the reaction tank to make a starch slurry with a mass ratio concentration of 60%, keep stirring and control the temperature of the starch slurry at 60°C, adjust the pH value of the starch milk to 10 with NaOH, and add starch to the starch milk 10% alkenyl succinic anhydride by mass, while using alkali to control the pH value of the system at 10; after reacting for 3 hours, adjust the pH value to 7 with acid, filter, wash 3 times with water, centrifuge, and dehydrate to obtain wet alkenyl succinic acid Starch ester; adding concentration is 99% ethanol in the reaction tank, the alkenyl succinic acid starch ester that will make is added in the reaction tank, is transferred into the starch slurry that mass ratio concentration is 55%, under stirring, adding concentration is 40 % NaOH, adjust the pH value of the starch slurry at 14, stir and heat up to 50°C, alkalize for 2 hours, then add chloroacetic acid with 85% starch mass, keep the slurry temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com