Design method of 0.35 um LDMOS high vltage power displaying driving element

A design method and display driving technology, applied in the direction of electric solid-state devices, semiconductor devices, static indicators, etc., can solve the problems of large total area of die, large working current, difficulty in shortening channel length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

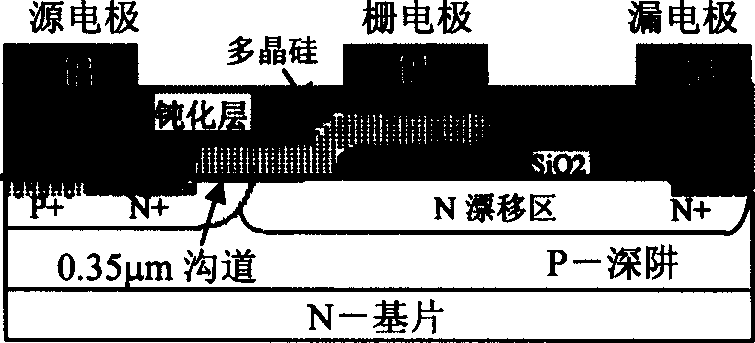

[0061] Figure 5 is the actual layout of the driving device composed of 4 0.35μm, LD-NMOS units connected in parallel (for clarity, some details are gated out). The channel length of the unit device is L=0.35μm, the total width W=160μm, and the gate oxide layer d ox =100,open voltage V T =0.7V. At gate voltage V G =4V, leakage current I D = 1mA / μm. 160 rows of drive array, unit area 28×40=1120μm 2 , The total area is 160×28×40=4480×40μm 2 . It can be changed to 160×14×80=2240×80μm according to needs 2 arrangement. In the latter arrangement, the wire current density reaches 1.6×10 6 / cm 2 , But because the duty cycle is less than 0.01, this scheme is feasible.

[0062] The plan view and the cross-sectional structure of LDPMOS are similar, but the doping is different. The most important difference is that the total channel width of the P tube is about 20 μm, which is 1 / 8 of the N tube, because it does not need to bear too much current.

[0063] Figure 6 is The layout of the lead c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap