Method of preparing imorganic-organic copolymer proton exchange membrance

A technology of proton exchange membrane and production method, which is applied in the production field of proton exchange membrane, can solve the problems of high temperature and water content requirements, inability to increase electrode reaction speed, low mechanical properties, etc., and achieve improved strength and stability, excellent moisture absorption performance, the effect of strong hygroscopic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh 40 grams of 30% silica sol solution, add 100 grams of 8% polyvinyl alcohol solution, stir evenly, and obtain a uniform solution;

[0030] (2) in above-mentioned solution, add 1 gram concentration and be the sulfuric acid solution of 20%, stir;

[0031] (3) casting the above solution on a glass plate to form a film, drying or drying at room temperature, volatilizing the water, and polymerizing the silica sol;

[0032] (4) Peel off the above film to obtain SiO 2 60% soft and transparent composite proton exchange membrane;

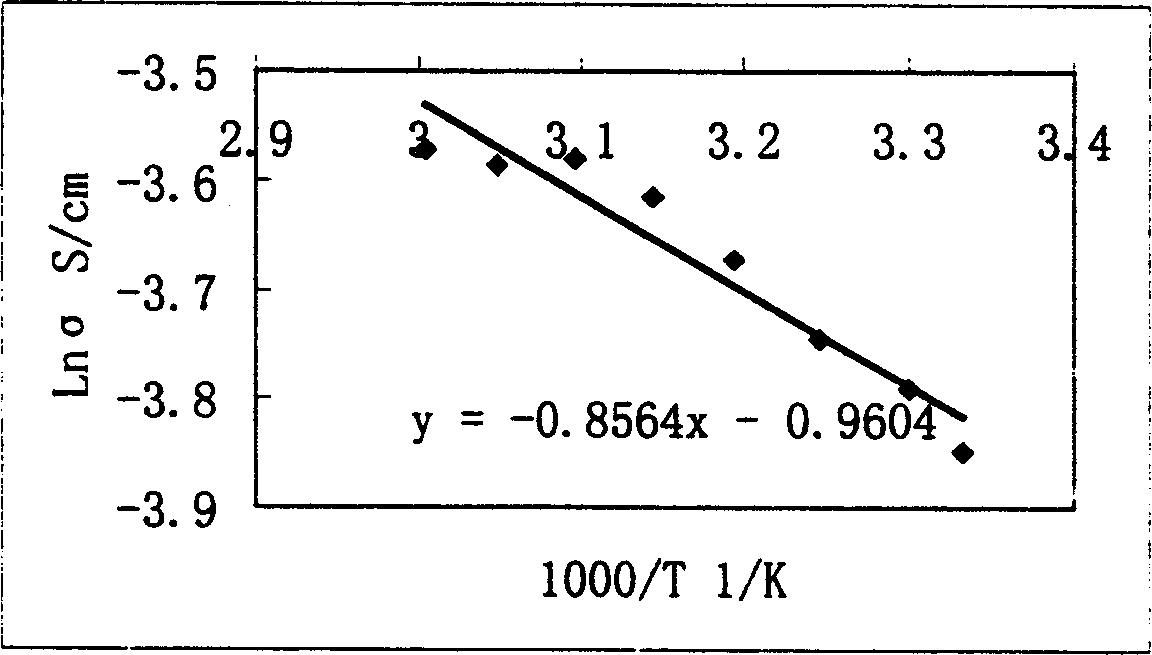

[0033] (5) soak the above film in 25°C 30% sulfuric acid solution for 4 hours, take out the acid solution that wipes the surface, and measure its conductivity as 1.12×10 -2 S / cm.

Embodiment 2

[0035] (1) Weigh 25 grams of 30% silica sol solution, add 0.5 gram of carboxymethyl cellulose, 25 grams of 8% polyvinyl alcohol solution, add 50 grams of water, stir evenly, and obtain a uniform solution;

[0036] (2) In the above solution, add 0.5 gram of tungstosilicic acid, 7 grams of sulfuric acid solution with a concentration of 60%, and stir evenly;

[0037] (3) casting the above solution on a glass plate to form a film, drying or drying at room temperature, volatilizing the water, and polymerizing the silica sol;

[0038] (4) Peel off the above film to obtain SiO 2 A composite proton exchange membrane with a content of 75% softness, whose conductivity was measured to be 4.76×10 -2 S / cm.

Embodiment 3

[0040] (1) Weigh 20 grams of 30% silica sol solution, add 6 grams of polyethylene glycol powder, stir evenly, add 50 grams of water, stir for 2 hours, and heat to 75°C at the same time to completely dissolve the polyethylene glycol to obtain a uniform solution ;

[0041] (2) in above-mentioned solution, add 5 gram concentration and be the sulfuric acid solution of 60%, stir;

[0042] (3) casting the above solution on a glass plate to form a film, drying or drying at room temperature, volatilizing the water, and polymerizing the silica sol;

[0043] (4) Peel off the above film to obtain SiO 2 50% soft composite proton exchange membrane;

[0044](5) The above-mentioned film is soaked in 30% sulfuric acid solution at a concentration of 25°C for 3 hours, and the acid solution on the surface is taken out to measure its conductivity as 3.64×10 -2 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com