Machine arrangement for dust-free chamber production program

A technology of clean room and program, applied in the direction of exposure device of photo-plate-making process, photo-plate-making process of pattern surface, identification device, etc., can solve the problems of waste of manufacturing time, simplicity, and reduction of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

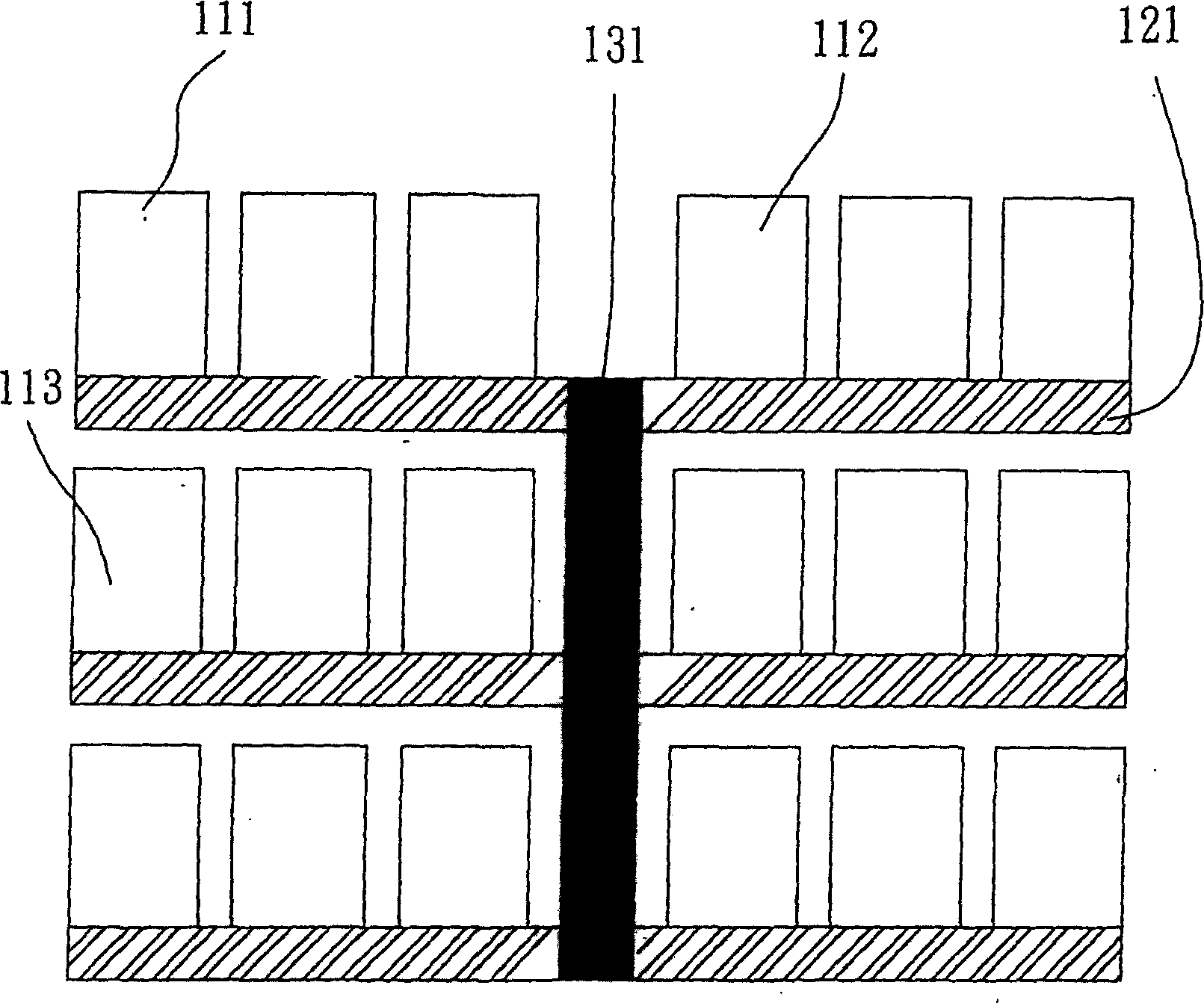

Embodiment 1

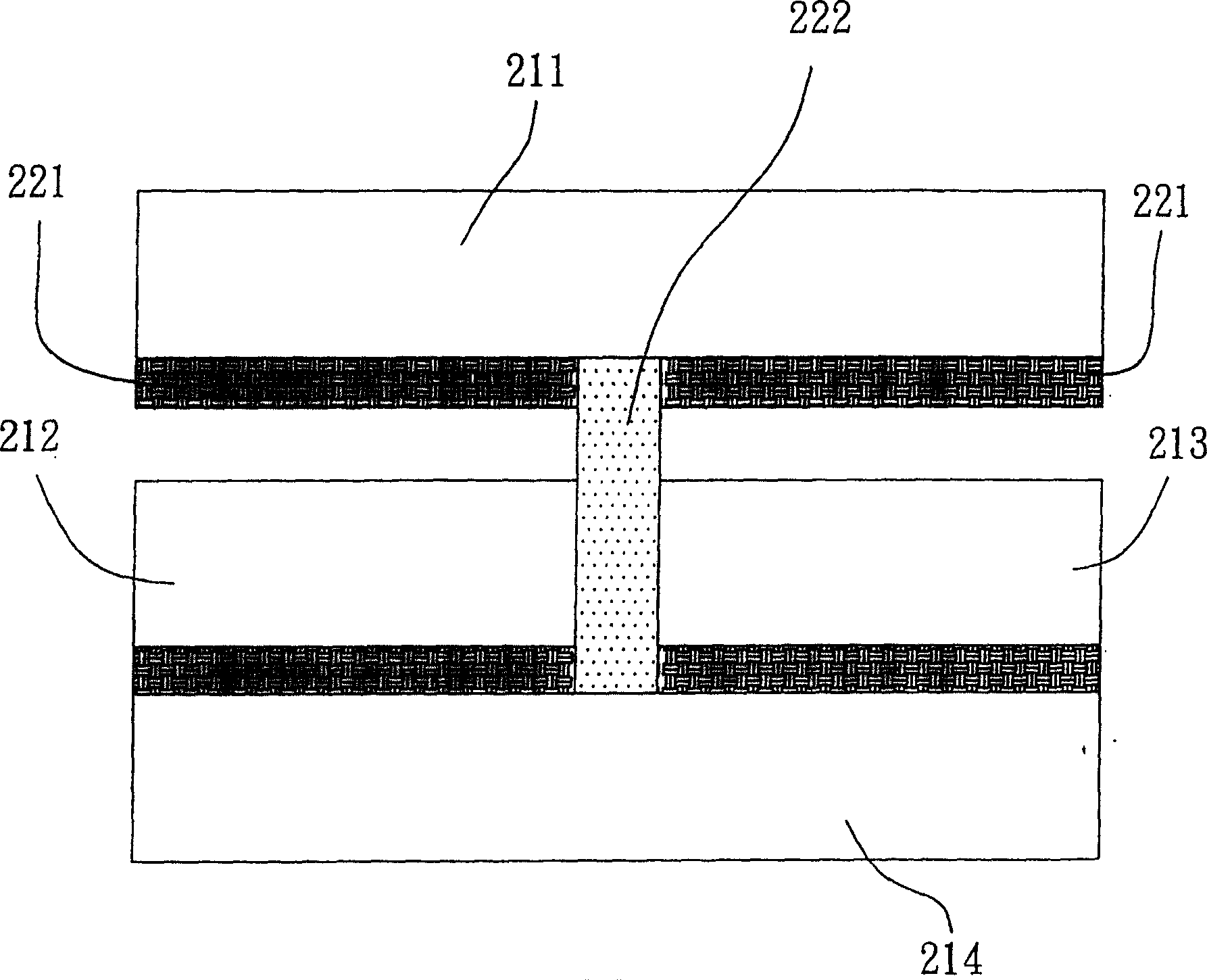

[0031] Please see first figure 2, which is a schematic diagram of machine configuration in Embodiment 1 of the present invention. In this embodiment, the machines with the same type of production process are mainly placed in the same row, and the processing substrate is transported by the robot arm or OHS of the storage cabinet. As can be seen in the figure, it is mainly divided into four types of machines, namely a photolithography machine 211, an etching and photoresist removal machine 212, and a thin film deposition machine 213, which are separated from each other by a storage cabinet, and AGV is not used at all, so AGV aisle is not needed, which greatly increases the utilization efficiency of space configuration. The substrate handling between the machines is performed by the robotic arm of the storage cabinet 221, or carried by the OHS 222, which further reduces the chance of particles falling on the substrate due to the approach of personnel or the movement of the AGV,...

Embodiment 2

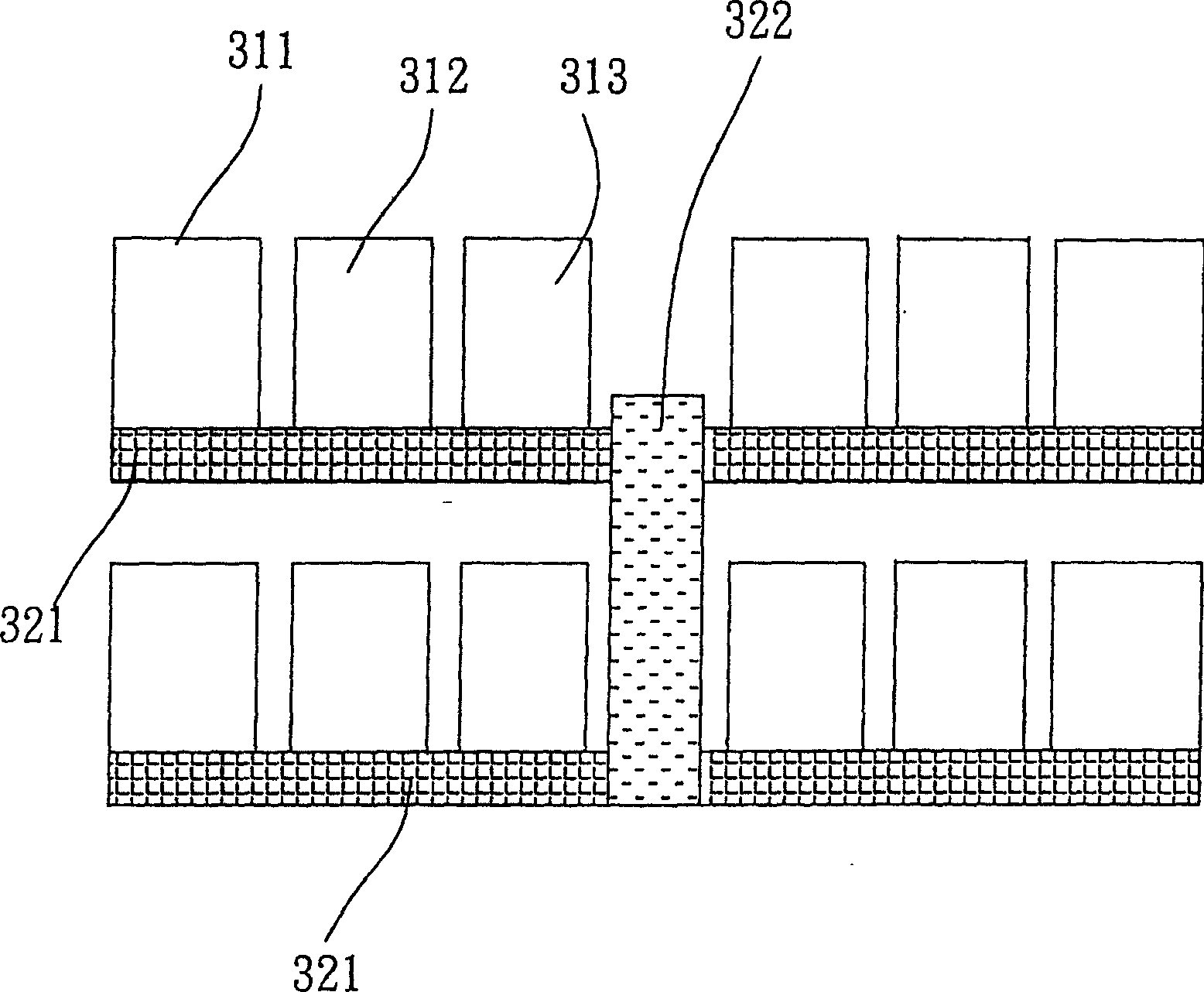

[0033] See image 3 , which is a schematic diagram of machine configuration in Embodiment 2 of the present invention. In this embodiment, the production process machines of the same layer, such as thin film deposition 311, lithography 312, and etching removal 313, etc., are placed on the moving line of the same storage cabinet 321. The advantage is that the connected storage cabinets And exempt the AGV from being exposed to the air when loading and unloading, causing the particles to fall on the substrate. On the other hand, this embodiment can also eliminate the space occupied by the AGV walkway, reduce equipment space costs, and at the same time prevent people from being hit by the AGV. At the same time, transported by the storage cabinet 321 or OHS322, personnel do not need to go to the front of the machine to operate, and also reduce the particles brought by personnel walking. In addition, placing the production process machines on the same layer on the same production p...

Embodiment 3

[0035] Please refer to FIG. 4 , which is a schematic diagram of an integrated machine according to Embodiment 3 of the present invention. As mentioned above, in order to improve the productivity of each machine, the integrated machine 412 proposed in this embodiment can integrate the production procedures such as etching, photoresist removal, surface treatment and cleaning into the same machine. To improve the productivity of this machine, on the other hand, it also reduces the redundant machine space and lowers the equipment cost. The front of the integrated machine 412 is connected with a photolithography machine 411, followed by a thin film deposition machine 413, and each machine is connected to a storage cabinet 421, and a glass substrate added by a robotic arm 422 Into the import port 423 of the storage cabinet 421.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com