Preparing method of freeze-dried antibiotic formulation

A drying, said technology, applied in the field of preparation of antibiotic freeze-dried dosage forms, can solve problems such as heat sensitivity and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

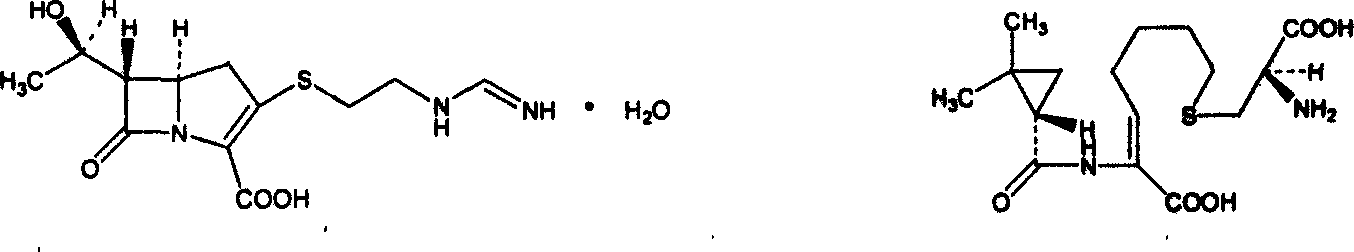

Image

Examples

Embodiment 1

[0025] Under the condition of nitrogen, 50g of sodium bicarbonate was added to 325g of water for injection, and 125g of imipenem was added, while stirring to obtain a clear solution with a pH value of 6.5-8.5. The solution was filtered with a 0.2 μm filter membrane, filled into a glass bottle, and placed in a freeze dryer (ChristAlpha1-2) to freeze-dry. -0.5 mbar) dry. After the main drying, the temperature was raised to 15° C., the vacuum degree was adjusted to 0.02 mbar, and the drying was continued for 2 hours to obtain an off-white freeze-dried product.

Embodiment 2

[0027] Under the condition of flowing nitrogen, 100 g of sodium bicarbonate was added to 500 g of water for injection, 250 g of cilastatin sodium was added, and stirred at the same time to obtain a clear solution with a pH value of 6.5-8.0. The solution was filtered with a 0.2 μm filter membrane, filled into a glass bottle, and placed in a freeze dryer (ChristAlpha1-2) to freeze-dry. The vial was cooled to -40°C, then raised to -20°C--5°C, vacuum (0.1 -0.5 mbar) dry. After the main drying, the temperature was raised to 20° C., the vacuum degree was adjusted to 0.02 mbar, and the drying was continued for 3 hours to obtain an off-white freeze-dried product.

Embodiment 3

[0029] Under nitrogen, 50g of sodium bicarbonate was added to 500g of water for injection, 125g of imipenem was added, and 125g of cilastatin sodium was added, while stirring to obtain a clear solution with a pH value of 6.5-8.5. The solution was filtered with a 0.2 μm filter membrane, filled into a glass bottle, and placed in a freeze dryer (Christ Alpha1-2) to freeze-dry. The vial was cooled to -45°C, then raised to -20°C--5°C, vacuum ( 0.1-0.5 mbar) dry. After the main drying, the temperature was raised to 15° C., the vacuum degree was adjusted to 0.02 mbar, and the drying was continued for 3 hours to obtain an off-white freeze-dried product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com