Manufacturing method of zinc tungstate humidity sensor

The technology of a humidity sensor and a manufacturing method, which is applied to electric solid devices, electrical components, circuits, etc., can solve the problems of instability, slow response, low sensitivity, etc., and achieve the effects of convenient operation, low cost and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Zinc oxide and tungsten trioxide were mixed at a ratio of 1:0.4, and the mixture was ground in a ball mill for 12 hours to achieve complete uniformity. Then add 2% cetyl alcohol, add a small amount of absolute ethanol, and continue grinding in the mortar for 2 hours. The mixture was pressed into a disc with a diameter of 10 mm and a thickness of 5 mm under a pressure of 100 MPa, and two gold wires were implanted in the disc as electrode leads. The wafer is heat-treated in a tube furnace, first at a heating rate of 10 °C / min to 400 °C, then at a heating rate of 2 °C / min to 700 °C, and finally at a heating rate of 1 °C / min to 800 °C °C and keep for 12 hours. Finally, the main components of the zinc tungstate humidity sensor are obtained.

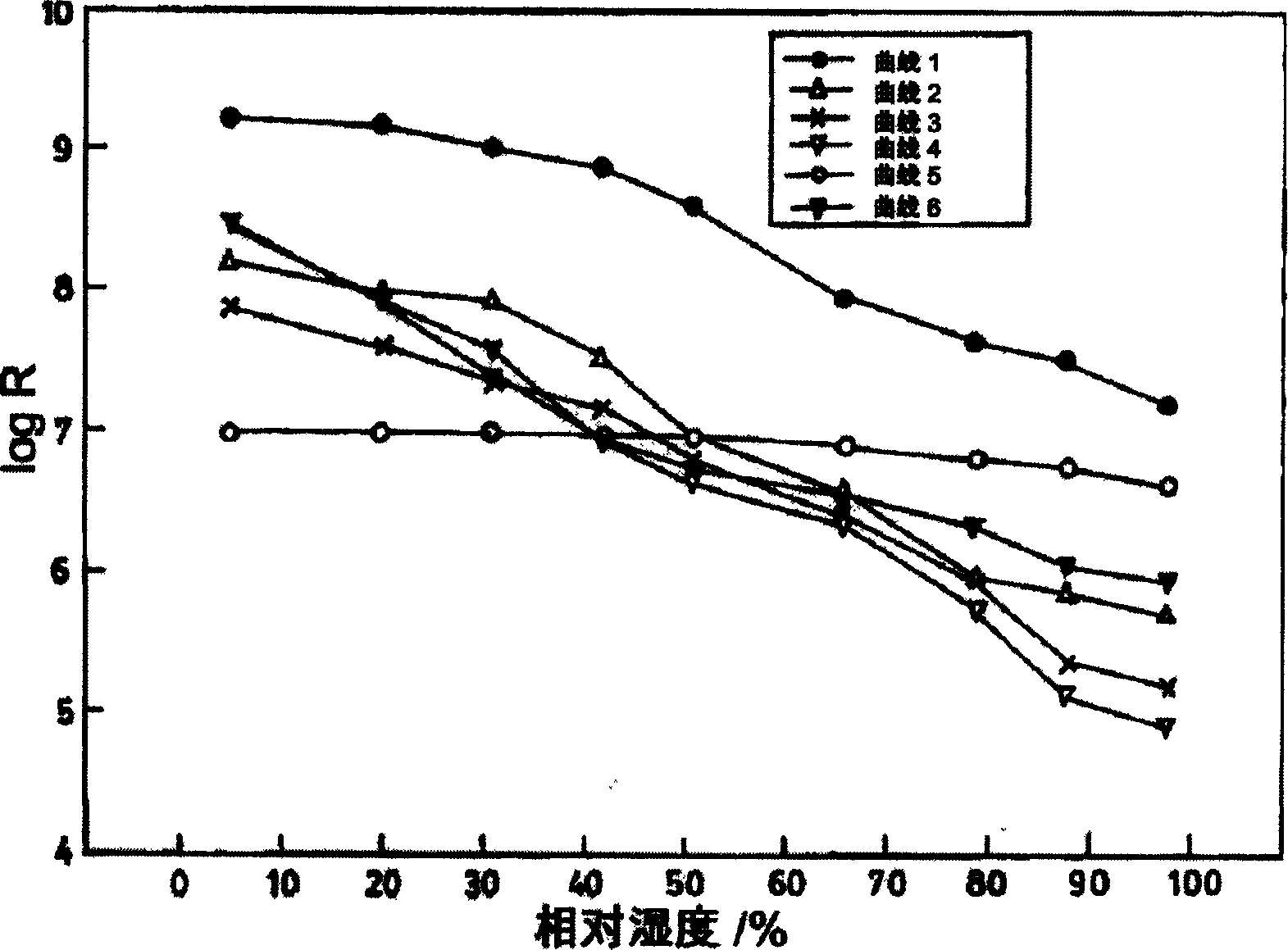

[0015] Through the test, the attached figure 1 The sensitivity curve in , from which curve 6 can be seen. Its sensitivity R 5% / R 98% for 3506. have a higher value.

[0016] In the figure, curve 5 is the pure zinc oxi...

Embodiment 2

[0017] Example 2: Zinc oxide and tungsten trioxide were mixed at a ratio of 1:0.2, and the mixture was ground in a ball mill for 12 hours to achieve complete uniformity. Then add 2% cetyl alcohol, add a small amount of absolute ethanol, and continue grinding in the mortar for 2 hours. The mixture was pressed into a disc with a diameter of 10 mm and a thickness of 5 mm under a pressure of 100 MPa, and two gold wires were implanted in the disc as electrode leads. The wafer is heat-treated in a tube furnace, first at a heating rate of 10 °C / min to 400 °C, then at a heating rate of 2 °C / min to 700 °C, and finally at a heating rate of 1 °C / min to 800 °C °C and keep for 12 hours. Finally, the main components of the zinc tungstate humidity sensor are obtained.

[0018] Through the test, the attached figure 1 The sensitivity curve in , from which curve 4 can be seen. Its sensitivity R 5% / R 98% for 341.

[0019] In the figure, curve 5 is the pure zinc oxide curve for comparison...

Embodiment 3

[0020] Embodiment 3: The method of this embodiment is basically the same as that of the above embodiment, except that the mixing ratio of zinc oxide and tungsten trioxide is 1:0.6 in this embodiment. The main components of the obtained zinc tungstate humidity sensor, its sensitivity curve is shown in the curve 3 of the accompanying drawing, and its sensitivity R 5% / R 98% for 463.

[0021] Curve 5 is the pure zinc oxide curve for comparison, without sensitivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com