Long carbonaceous molding, long carbonaceous product, and method of production thereof

A technology for long-sized and formed bodies, applied in the field of long-sized carbon formed bodies, which can solve the problems of different wall thicknesses between the curved end and the central part, and the inability to obtain carbon products, etc., and achieve good results in mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

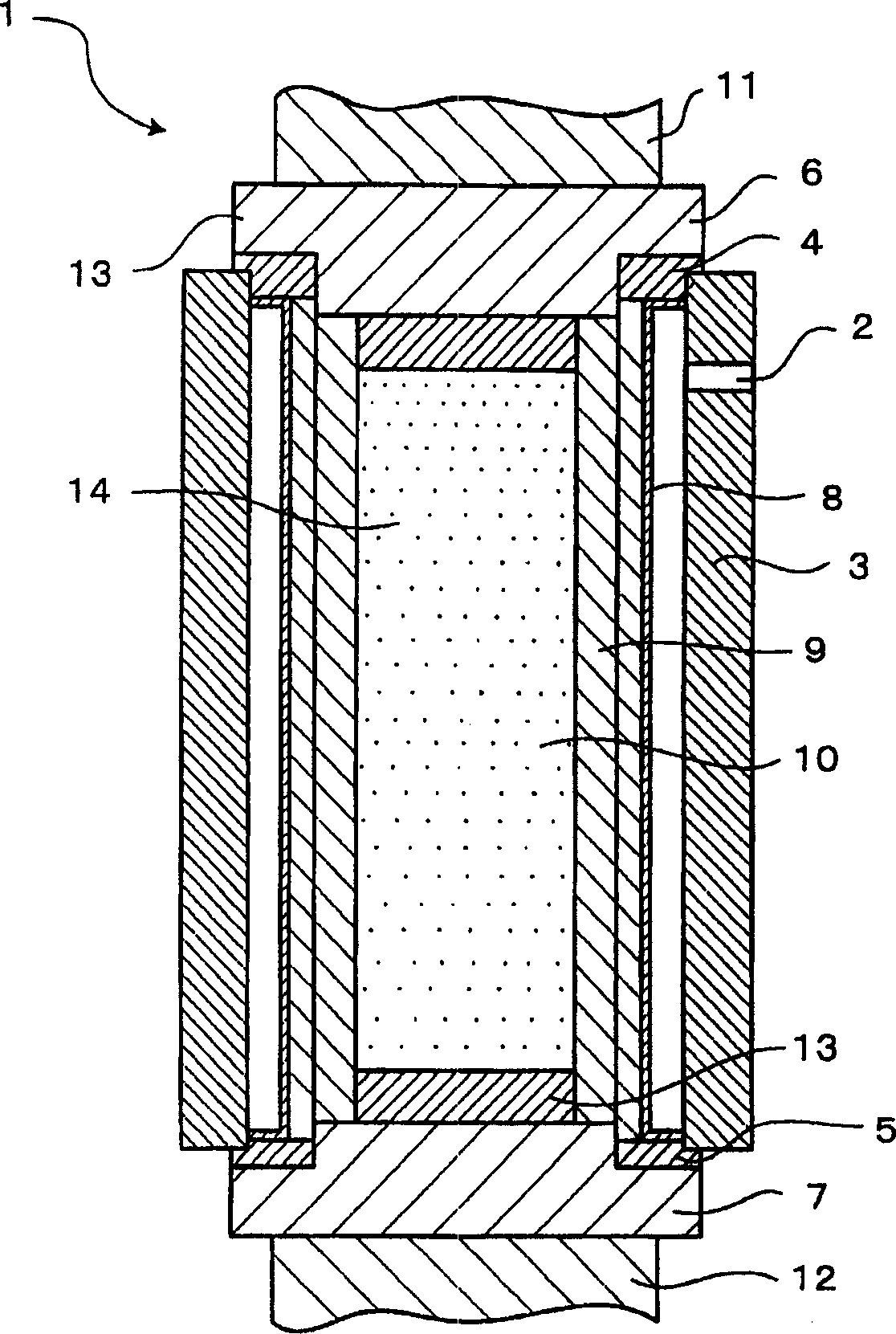

[0064] First, the formation of a long carbon molded body using a dry CIP apparatus will be described. As the raw material powder, carbon powder and binder pitch were kneaded, pulverized to an average particle diameter of 15 μm after kneading, and kneaded again with copper powder having an average particle diameter of 5 μm after pulverization. And the ratio of carbon powder and copper powder is 2:3.

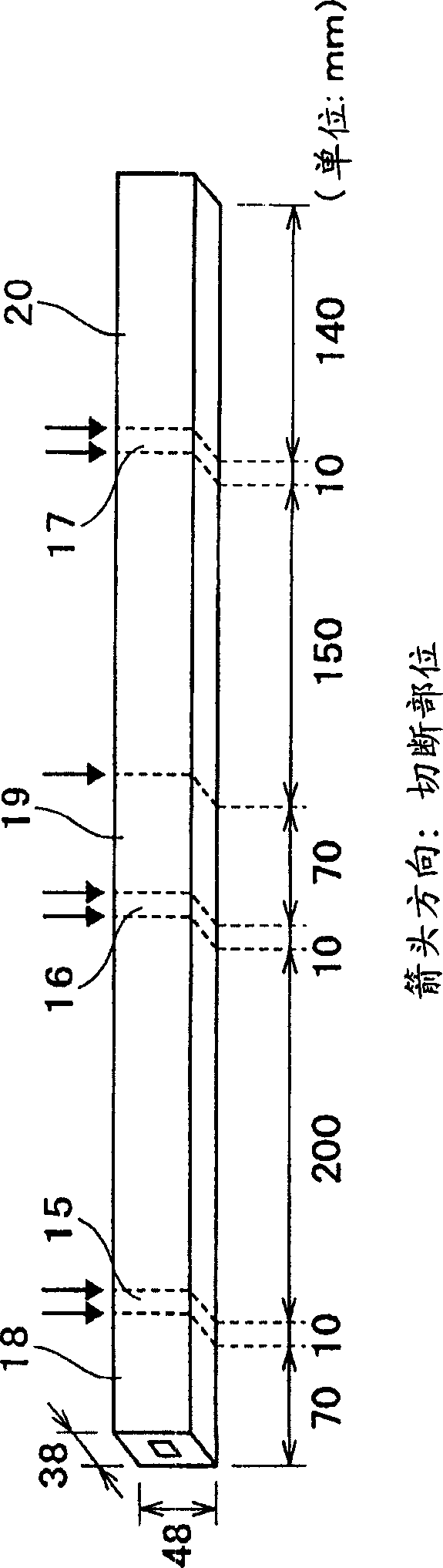

[0065] Next, a molded body is molded from the raw material powder using the dry CIP apparatus described in the above embodiment. Specifically, the forming pressure of the dry CIP device is 343MPa, and the forming size is 48×38×652 (unit: mm), and the forming weight is 3099g. figure 2 A long carbon molded body as shown.

[0066] according to figure 2 This elongated carbon molded body was cut out at the dimensional positions as shown. Specifically from figure 2 Starting from the left end of the long-sized carbon shaped body, cut it into 70mm shaped body 18, 10mm shaped body ...

Embodiment 7

[0076] As raw material powder, carbon powder and binder pitch were kneaded, and after kneading, pulverized to an average particle diameter of 30 μm. Next, a molded body is molded from the above-mentioned raw material powder using the CIP apparatus described in the above-mentioned embodiment. Specifically, the forming pressure of the dry CIP device is 100MPa, the forming size is φ50×650 (unit: mm), and the forming weight is 2050g. Figure 8 The long molded body 28 as shown is then heat-treated at 1200°C in a sintering furnace. The molded body 28 subjected to this heat treatment was used as a sample of Example 7.

Embodiment 8

[0082] The sample of Example 7 was applied to a resin-impregnated molded body as a sample of Example 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com