Self-emulsified alcoholic acid resin and its preparing method

An alkyd resin and self-emulsifying technology, which is applied in inks, household utensils, applications, etc., can solve the problems of alkali resistance, poor hydrophilicity, and limited application range, and achieve strong hydrophilicity and self-emulsification, increase Resin structure, effect of improving alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] mn

Embodiment 2

[0044] Adopt the method for embodiment 1, cool down to 250 DEG C after insulated for 35 minutes, add 22 kilograms of C having a boiling range of 200~210 DEG C 12 Linear alkane solvent, then add other raw materials to prepare ink, the formula is as follows:

[0045] Self Emulsifying Alkyd 10%

[0046] Gelled High Acid Value Phenolic Resin Oil 25%

[0047] Phenolic resin oil 10%

[0048] Pigment: 8%

[0049] CaCO 3 : 35%

[0050] TiO 2 :2%

[0051] BaSO 4 : 5%

[0052] Cobalt isozincate (desiccant): 1%

[0053] Solvent (C12 alkanes): 4%

[0054] That is, inks for printing intaglio engravings of securities are obtained.

Embodiment 3

[0056] The ink of Example 2 is tested for alkali resistance: the prepared ink is coated on a sample strip, and immersed in 2% NaOH aqueous solution for 0.5 hour, taken out, rinsed, and air-dried for rating.

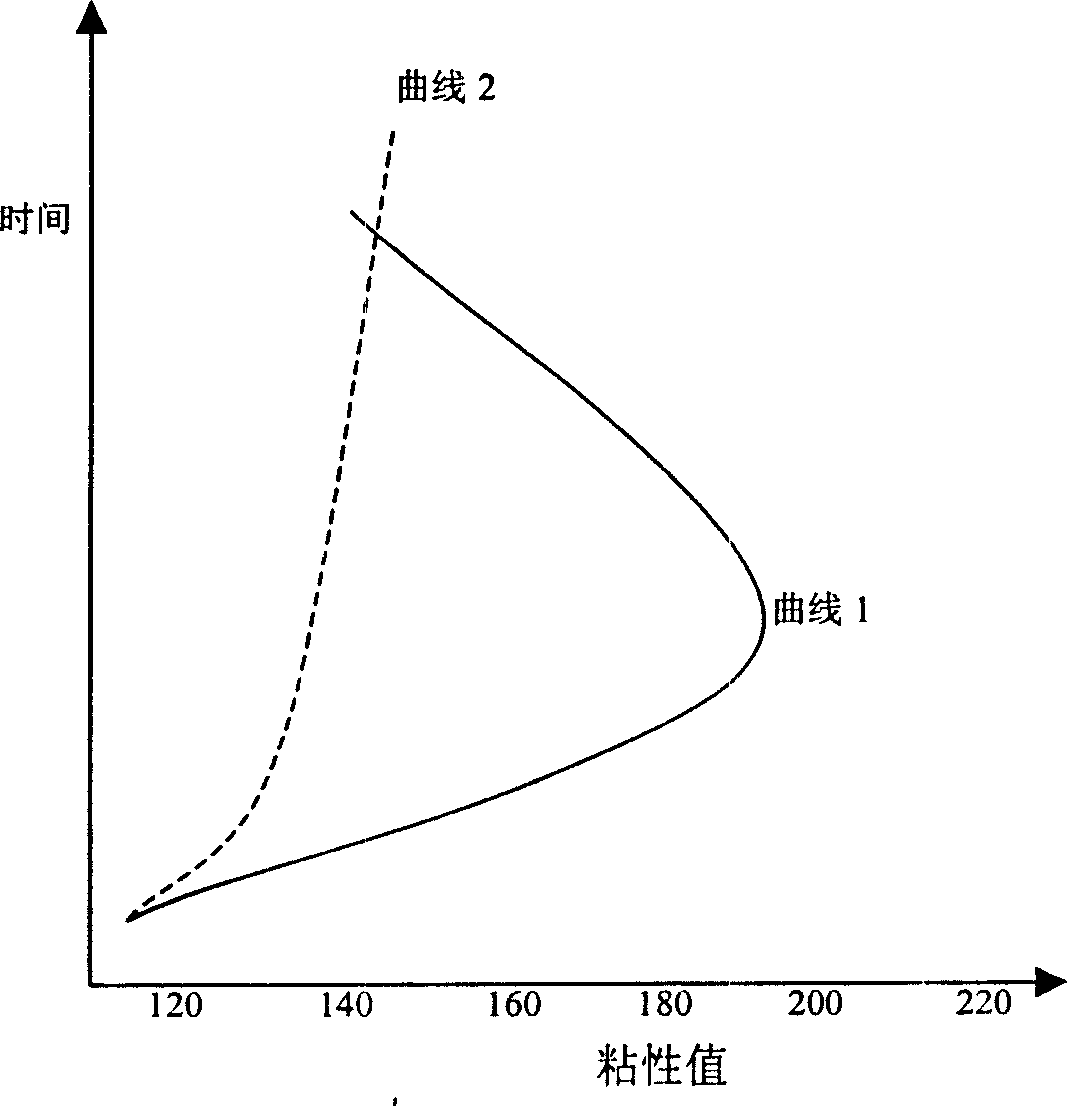

[0057] The ink of embodiment 2 is carried out the release speed of solvent is tested, and its result sees figure 1 . Among the figure, curve 1 is the data of embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com