Special electric cables and their pretective covering materials in environment with strong lightings, strong ultraviolet radiation, large temperature differential and cold

A special cable and strong ultraviolet technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of rapid aging, large construction traction force, poor low temperature performance of plastic materials, etc., and achieve enhanced electromagnetic shielding performance and lightning resistance performance , The effect of improving the dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 Preparation of black cable plastic

[0044] Take 70 parts of black polyvinyl chloride cable material as the main material, 30 parts of vulcanized nitrile rubber powder as plasticizer, and 2 parts of carbon black as light stabilizer, put them in the reactor, and mix them evenly at 160-180 °C , to prepare a nitrile compound modified polyvinyl chloride black cable plastic containing a light stabilizer.

Embodiment 2

[0045] Example 2 Preparation of red cable plastic

[0046] Take 70 parts of red polyvinyl chloride cable material as the main material, 30 parts of vulcanized nitrile rubber powder as plasticizer, and 0.2 part of UV-531 ultraviolet absorber as light stabilizer. Mix evenly at high temperature to prepare nitrile compound modified polyvinyl chloride cable plastic containing light stabilizer.

Embodiment 3

[0047] Example 3 Preparation of blue cable plastic

[0048] Take 70 parts of blue polyvinyl chloride cable material as the main material, 30 parts of vulcanized nitrile rubber powder as plasticizer, and 0.3 part of UV-9 ultraviolet absorber as light stabilizer. Mix evenly at a temperature of ℃ to prepare a nitrile compound modified polyvinyl chloride cable plastic containing a light stabilizer.

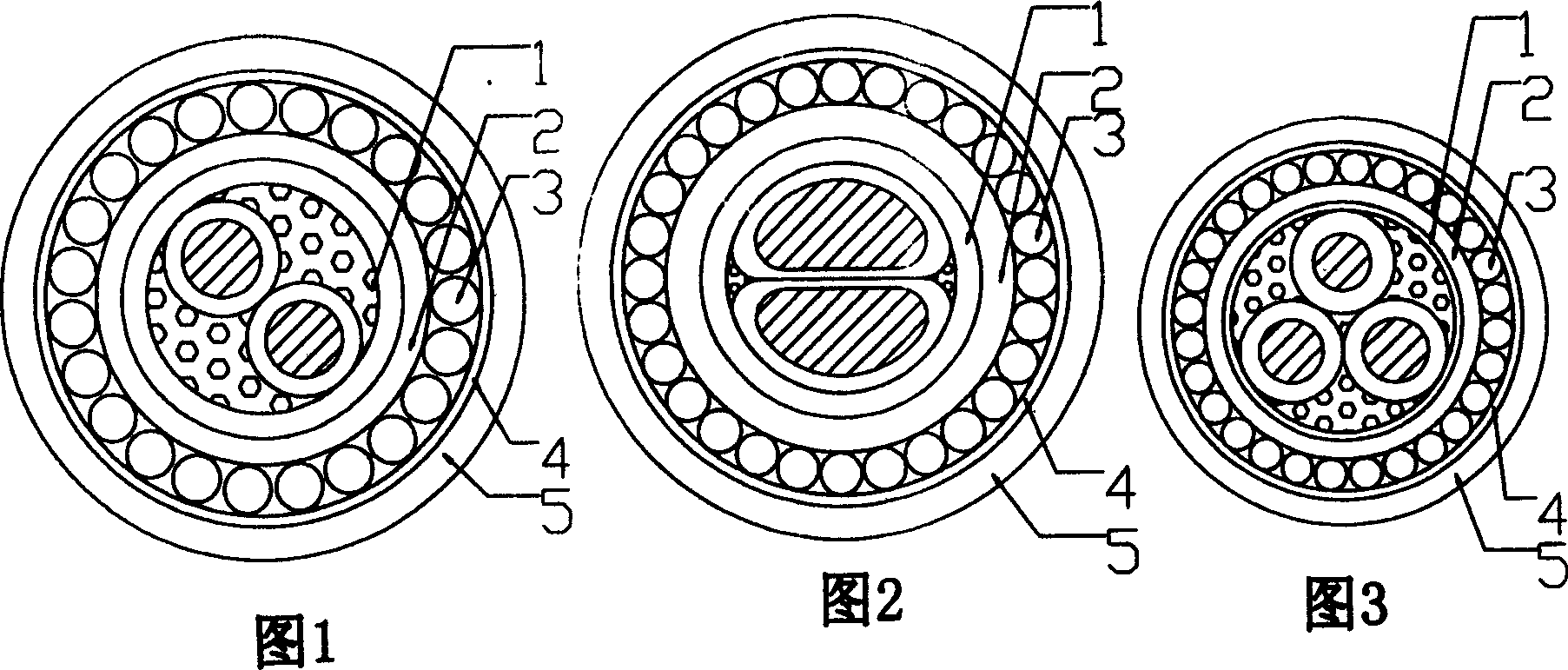

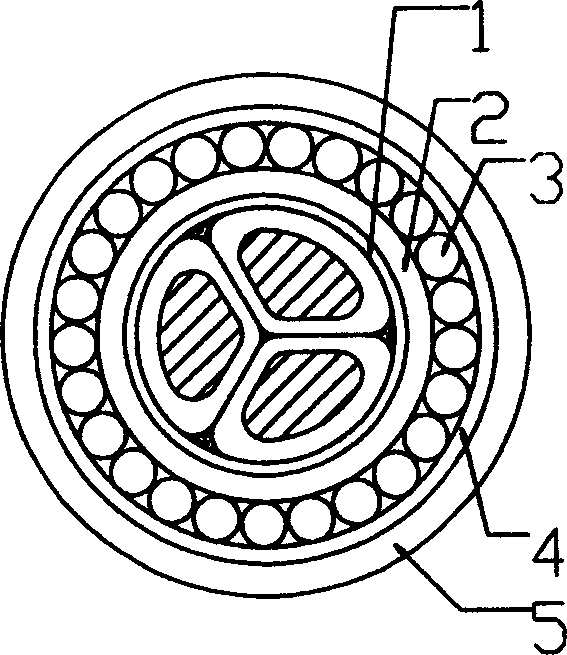

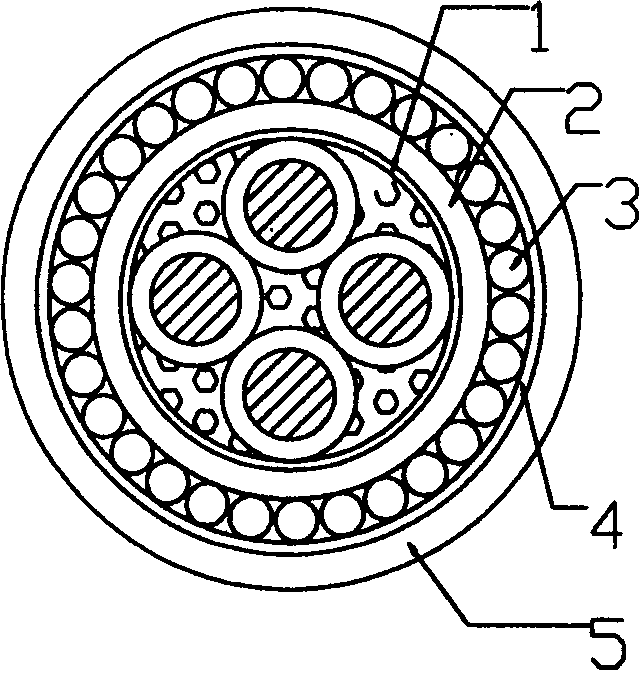

[0049] --The structure of the cable

[0050] Embodiment 1 Two-core circular conductor 0.6 / 1kv cable

[0051]Referring to Fig. 1: a two-core round conductor cable is composed of a cable core 1 with two round conductors, a cushion layer 2, a steel wire armor layer 3, a reinforcement layer 4 and a sheath 5, and the sheath 5 is implemented by the above-mentioned embodiment 1 or Example 2 or Example 3 Extruded from a nitrile compound modified polyvinyl chloride material containing a light stabilizer, its thickness is 10-20% larger than the sheath thickness of cables of the same specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com