Method for regenerating anode materials of waste lithium ion secondary battery

A positive electrode material and secondary battery technology, applied in the field of positive electrode material regeneration, can solve the problems of large chemical reagent consumption, complicated separation process, and easy pollution, and achieve significant economic benefits, simple process, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

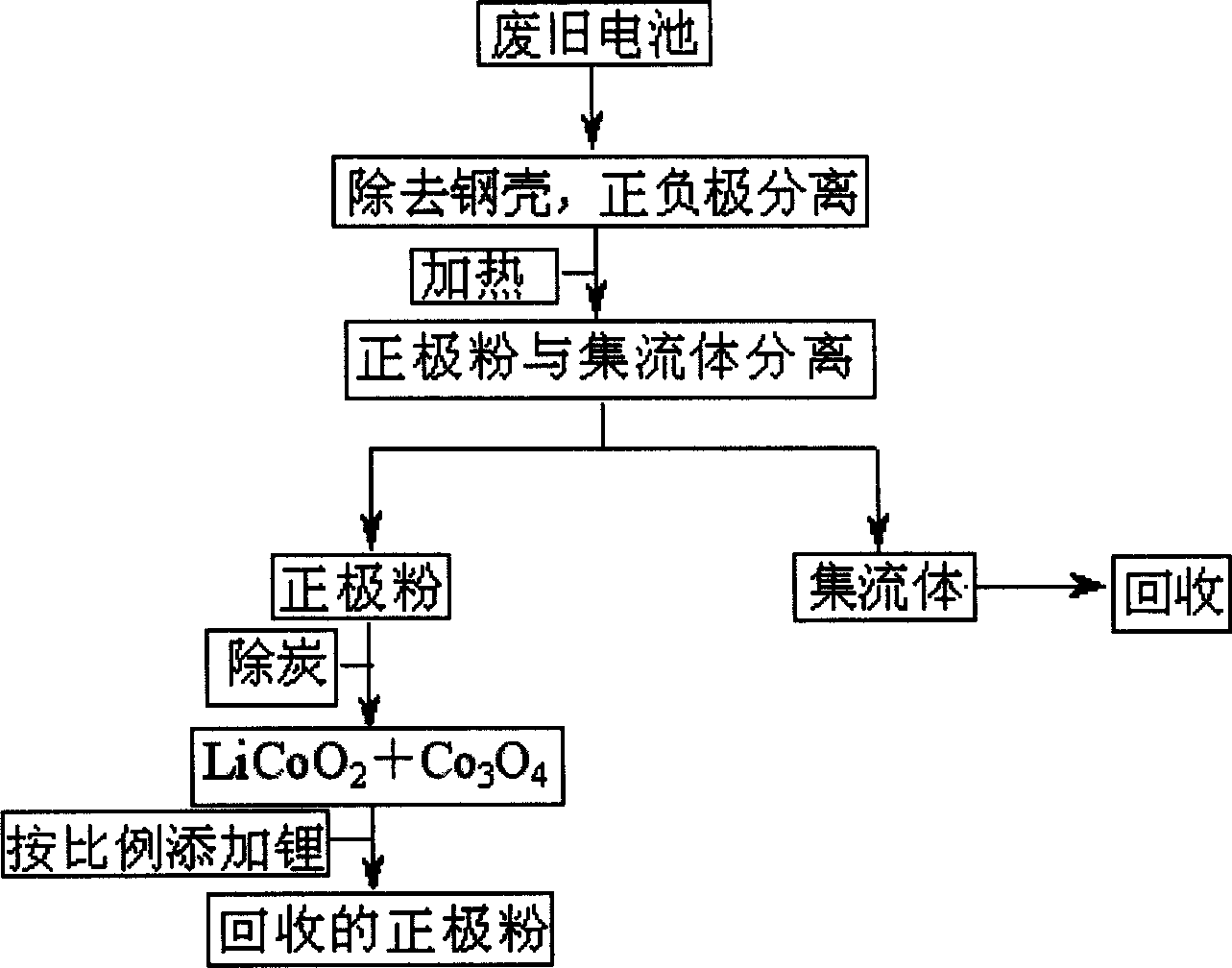

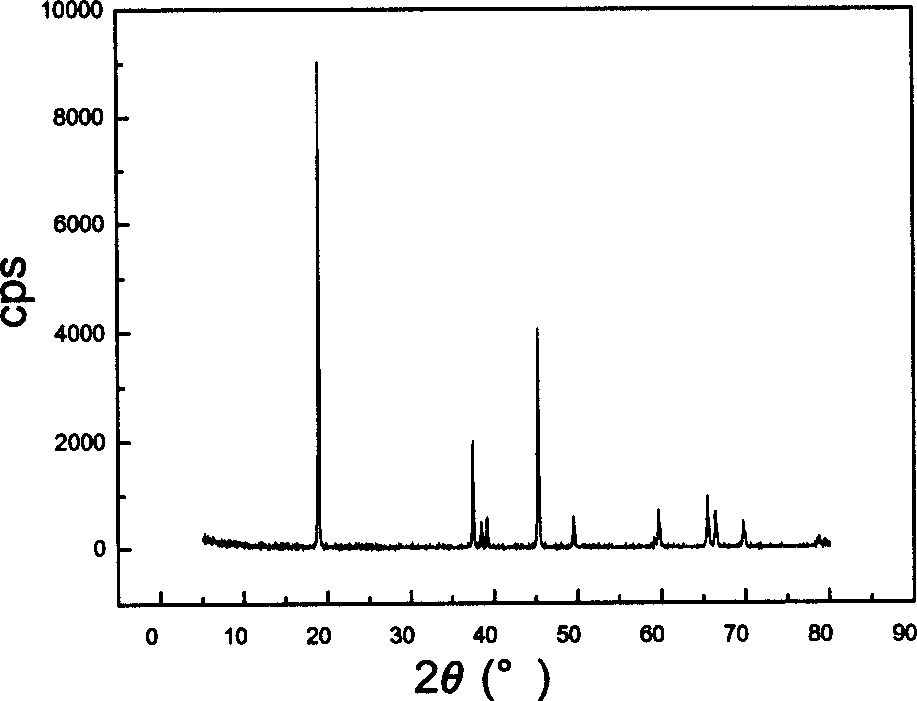

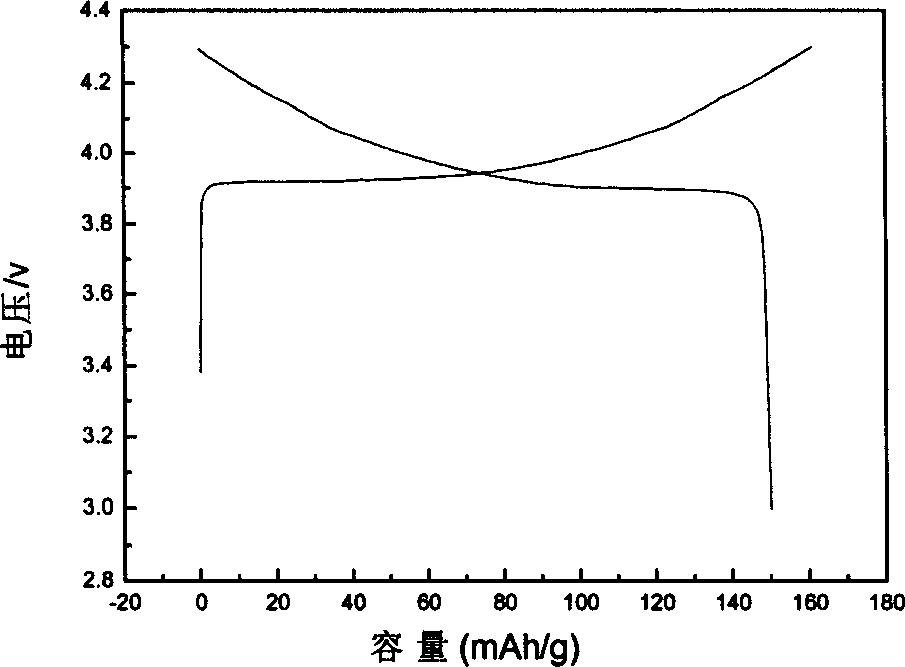

Embodiment 1

[0022] Cut open the casing of the 17500-type lithium-ion secondary battery that failed the charge-discharge cycle, sort out the positive electrode sheet, and heat it at 400°C for 6 hours in an air atmosphere to remove the adhesive; mechanically bond the aluminum foil substrate with the positive electrode The materials are separated, and the separated positive electrode material is roasted at 800°C for 5 hours in an air atmosphere to remove conductive agents such as carbon; the percentage content of lithium and cobalt elements in the high-temperature roasted positive electrode material is analyzed, based on the content of cobalt element, Use Li 2 CO 3 Supplement the lithium element so that the atomic ratio of lithium and cobalt is 1.05:1.00, mix the positive electrode material with adjusted ratio evenly, use a tubular resistance furnace, pre-fire and roast in the air atmosphere, and grind through a 38.5 μm sieve to obtain Reused cathode material LiCoO 2 , the regeneration flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com