Process for preparing compound inorganic germicide

An inorganic antibacterial agent and composite technology, which is applied in the field of preparation of composite inorganic antibacterial agents, can solve the problems of low removal rate, low photocatalyst activity, secondary pollution, etc., and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

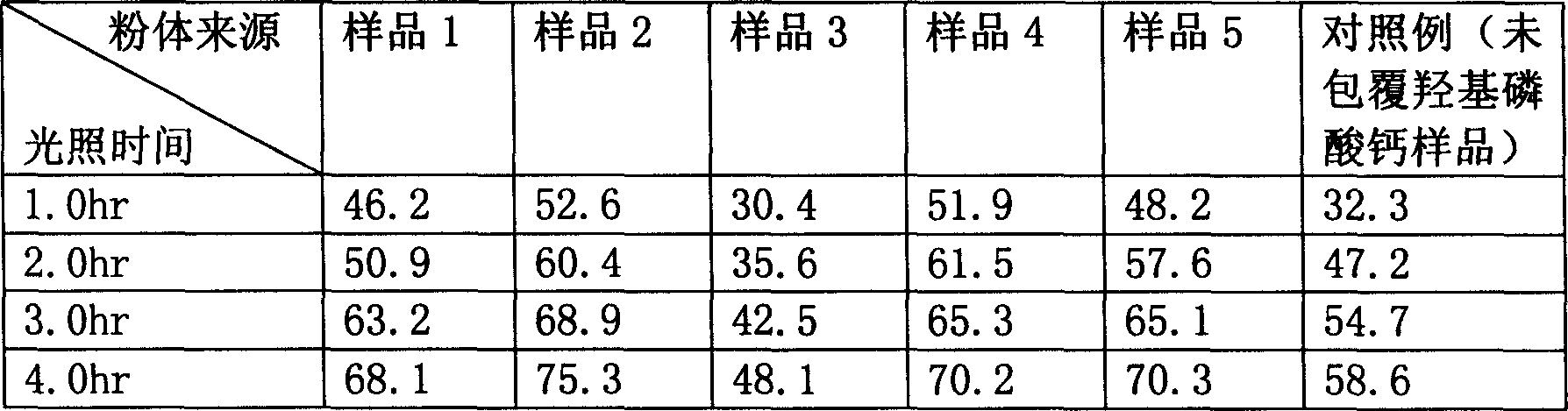

Embodiment 1

[0018] Embodiment 1: Get 33.4g of anatase type titanium dioxide with an average particle diameter of about 20nm and make it into 200ml deionized aqueous solution, disperse it in the microreactor for about 20min, control the rotating speed to be 3000rpm, and be 10% of titanium dioxide according to the amount of hydroxyapatite, Add the ammonium dihydrogen phosphate deionized aqueous solution dropwise into the mixed slurry of titanium dioxide and calcium nitrate, then stir and react for 3 hours to obtain a composite powder suspension; 3 Make a 1.5g / l solution with deionized water and add it dropwise to the composite powder suspension, the theoretical silver loading is 2% (wt), stir for 2 hours, control the pH to 6-7, then suction filter, wash, and finally Dry the composite antibacterial agent at 80-100°C, and then heat-treat at 400°C for 1 hour to obtain sample 1

Embodiment 2

[0019] Embodiment two: get the anatase type titanium dioxide 33.4g that average particle size is about 20nm and be made into 200ml deionized aqueous solution, disperse about 20min in the microscopic reactor, control rotating speed is 4000rpm, according to the hydroxyapatite amount is 20% of titanium dioxide, Add the ammonium dihydrogen phosphate deionized aqueous solution dropwise into the mixed slurry of titanium dioxide and calcium nitrate, then stir and react for 3 hours to obtain a composite powder suspension; 3 Make a 1.5g / l solution with deionized water and add it dropwise to the composite powder suspension, the theoretical silver loading is 2% (wt), stir for 2 hours, control the pH to 6-7, then suction filter, wash, and finally The composite antibacterial agent was dried at 80-100°C, and then heat-treated at 400°C for 1 hour to obtain sample 2.

Embodiment 3

[0020] Embodiment three: get the anatase type titanium dioxide 33.4g that average particle size is about 20nm and be made into 200ml deionized aqueous solution, disperse about 20min in the microscopic reactor, control rotating speed is 4000rpm, according to the amount of hydroxyapatite is 40% of titanium dioxide, Add the ammonium dihydrogen phosphate deionized aqueous solution dropwise into the mixed slurry of titanium dioxide and calcium nitrate, then stir and react for 3 hours to obtain a composite powder suspension; 3 Make a 1.5g / l solution with deionized water and add it dropwise to the composite powder suspension, the theoretical silver loading is 2% (wt), stir for 2 hours, control the pH to 6-7, then suction filter, wash, and finally The composite antibacterial agent was dried at 80-100°C, and then heat-treated at 400°C for 1 hour to obtain sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com