Micro suspension arm beam driven light intensity modulated type optic-fiber hydrogen sensor

A technology of light intensity modulation and hydrogen sensor, which is applied in the field of sensors, can solve the problems of reduced sensor accuracy and complex sensor structure, and achieve the effects of simplifying the structure, solving the problem of easy damage, and improving the axial driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

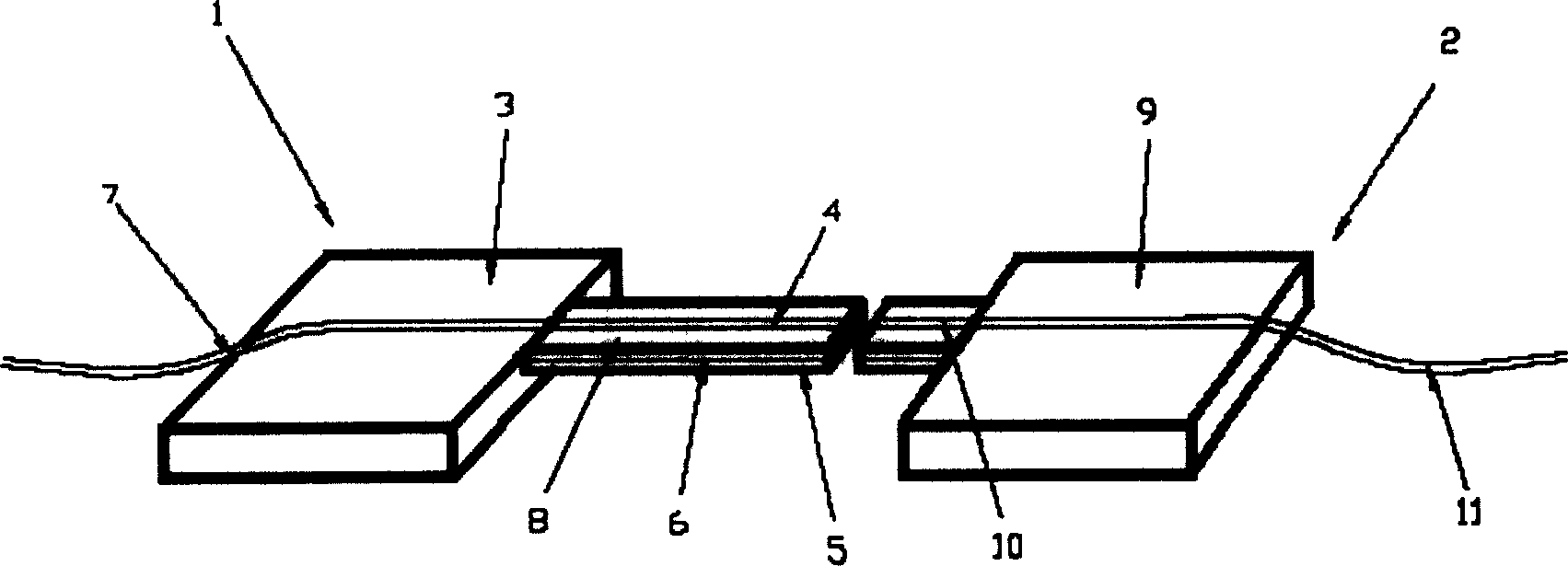

[0009] Such as figure 1 As shown, the present invention consists of a light source emitting part 1 and a light source receiving part 2. The light source emitting part 1 includes: a first Si base 3, an optical fiber probe 4, a palladium film 5, a substrate copper-nickel film 6, and a first fiber tail 7 , silicon arm beam 8, its connection relationship is: the palladium film 5 absorbing hydrogen is attached to the substrate copper-nickel thin film 6 which does not absorb hydrogen to form a double-layer film structure, which is attached to the silicon arm beam 8 in turn. One end of the silicon arm beam 8 is fixed on the first Si base 3, the optical fiber probe 4 with light source is attached to the V-shaped groove in the center of the silicon arm beam 8, and the first fiber tail 7 of the optical fiber is connected to the light source. The light source receiving part 2, that is, the light source reference platform, includes: a second Si base 9, an optical fiber interface 10, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com