Fuel cell composite material double polar plate and its making method

A composite material and fuel cell technology, used in fuel cells, fuel cell parts, battery electrodes, etc., can solve the problem of high cost and achieve the effects of low processing cost, high comprehensive performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Mix 100 g of bisphenol A epoxy resin and 16 g of triethanolamine evenly, add 125 g of reagent graphite powder, and mix for 15 minutes. (2) Transfer a certain amount of the above-mentioned mixture into the molding die, and close the dies. (3) The mold is placed in a hydraulic press equipped with heating and temperature control devices, and molded at a temperature of 120° C. and a pressure of 10 MPa, and the molding time is 2 hours. (4) After the molding process is finished, take out the product and continue curing at 100°C for 24 hours to obtain a finished product.

Embodiment 2

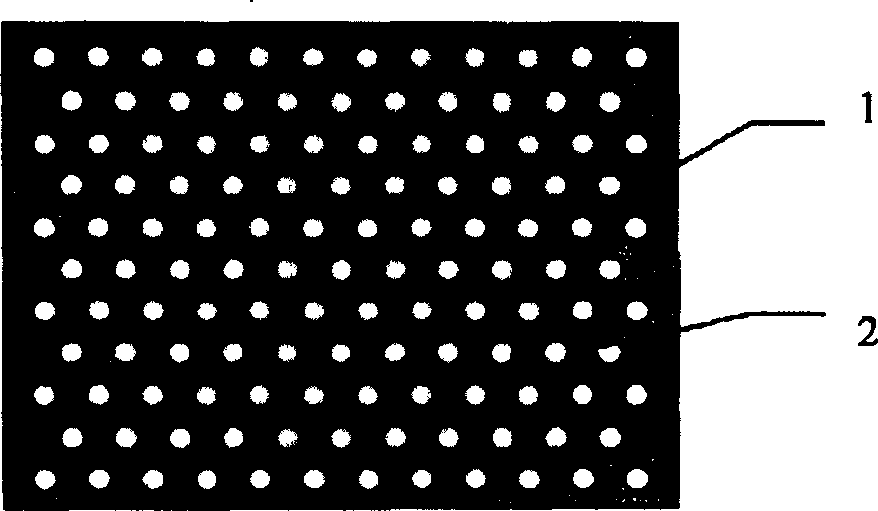

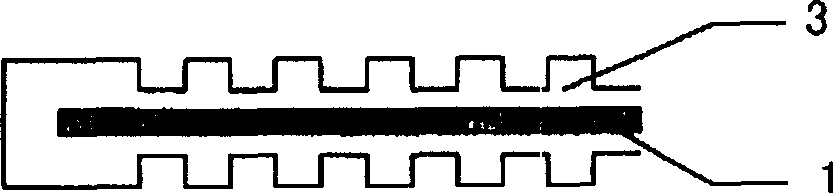

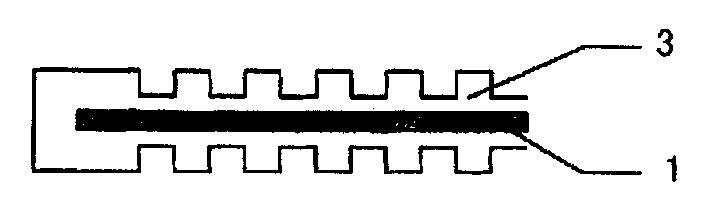

[0040]With embodiment 1, only in the step (2), the compound is divided into two parts on average, and one of them is taken in the lower mold of packing die mold, and spreads flat; Place the thick perforated zinc plate of 1.5mm on it; Fill with another mix and spread evenly; close the upper mold. In step (3), the temperature is 80° C., and the molding time is 4 hours.

Embodiment 3

[0042] With embodiment 2, just add reagent graphite powder 480g, polyparaphenylene terephthalamide (PPTA) fiber 20g in the step (1). The 1.5mm thick perforated zinc plate in step (2) is changed into a 1mm thick perforated copper plate. In step (3), the temperature is 150° C., and the molding time is 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com