LCD light valve taking copper phthalocyanine-cadmium sulphide multilayer complex film as photosensitive layer and preparing process thereof

A multi-layer composite film and liquid crystal light valve technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems that it is difficult to realize the photosensitive layer of high-resolution liquid crystal light valves, and does not have photoconductive anisotropy, so as to improve the Effects of lifetime and resolution, large absorption coefficient, and improved resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

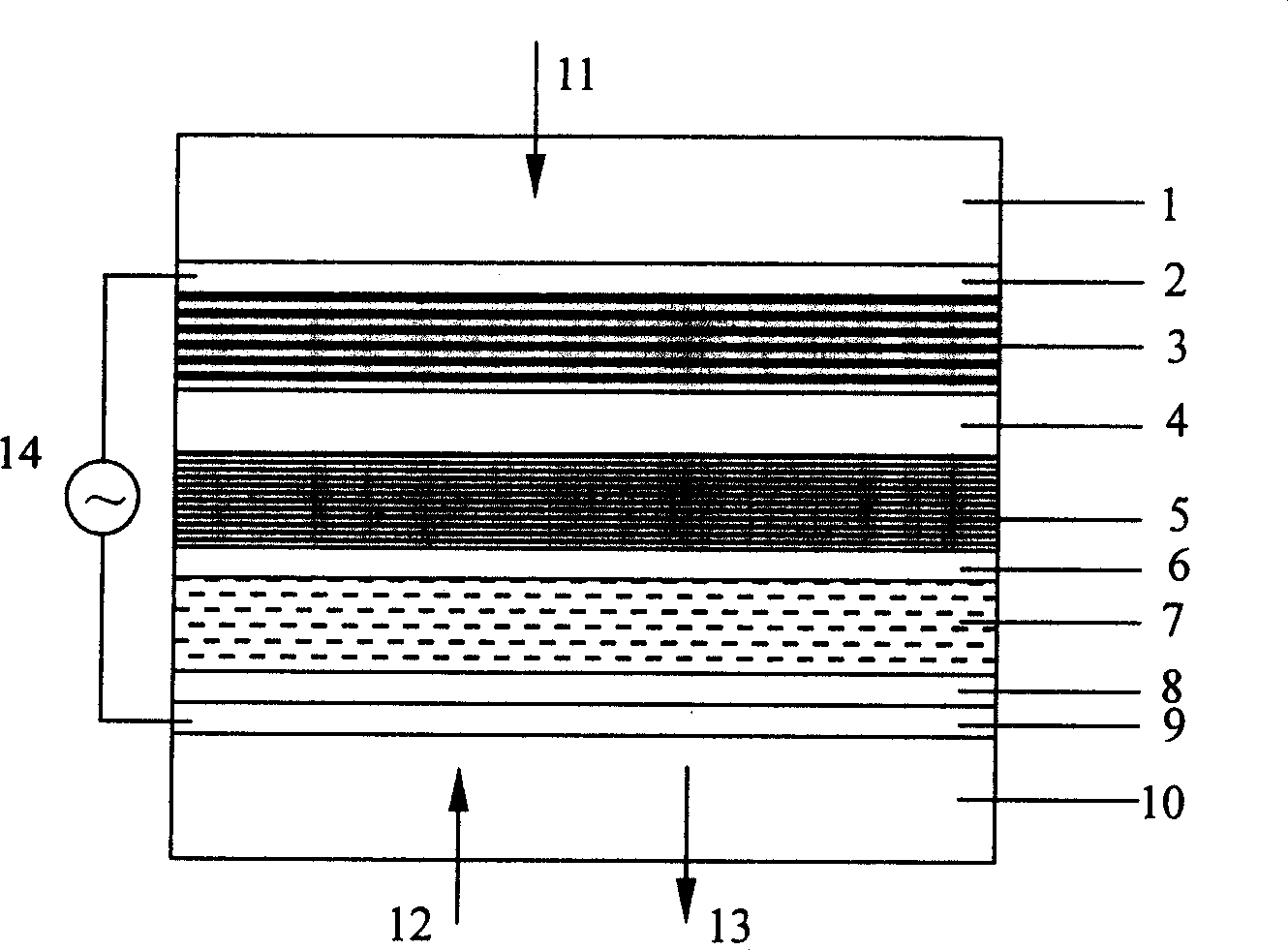

[0040] like figure 1As shown, the writing light 11 passes through the first glass substrate 1 and the first transparent conductive film (indium tin oxide film ITO) 2 evaporated on the first glass substrate 1, and reaches the first transparent conductive film prepared by the vacuum evaporation method. The photosensitive layer 3 of the copper phthalocyanine / cadmium sulfide (CuPc / CdS) multilayer composite film on the film 2, after the light enters the light blocking layer (cadmium telluride CdTe) 4 with a large absorption coefficient, combined with the intermediate dielectric reflection layer 5 , the writing light 11 and the reading incident light 12 are isolated, so that the writing light 11 cannot be irradiated on the liquid crystal layer 7 to affect the imaging quality. Both sides of the liquid crystal layer 7 are in direct contact with the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com