Water-solubility acidity temporary plugging agent for press cracking

A technology of fracturing acidification and temporary plugging agent, which is applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problems of poor plugging effect, low dissolution rate, low plugging strength, etc. Achieve the effect of improving the actual use efficiency, fast dissolving speed and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, water-soluble fracturing acidification temporary plugging agent of the present invention, it contains three kinds of components of bone glue, sulfonated pitch and guar gum, wherein the weight ratio of three kinds of components is: bone glue: sulfonated pitch: guar gum is 6.5:3:1.

[0020] The preparation method adopted is: measure 65Kg of water and heat it at 75°C, add 65Kg of bone glue, stir while adding, so that the bone glue is completely dissolved, after the temperature drops to 45°C, add 30Kg of sulfonated asphalt, add while adding Stir evenly, then add 10Kg of guar gum, stir vigorously to make the components evenly mixed, pour it on the container, spread it into a cake shape with a thickness of about 3mm, dry it naturally, crush it with a pulverizer and sieve it, and select a particle size diameter of 3 -6mm is used as a finished temporary plugging agent.

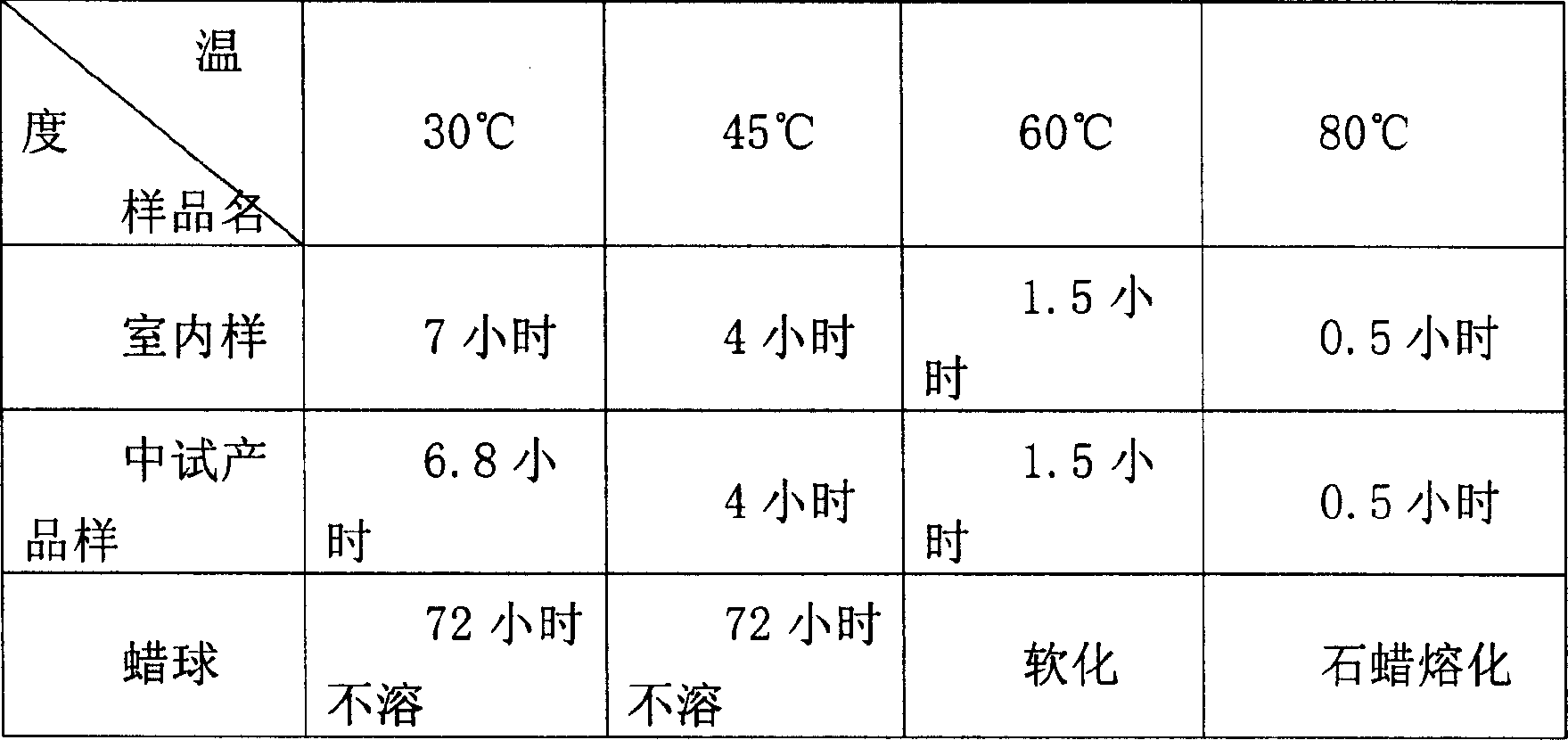

[0021] Through the solubility test and pressure resistance test of the finished temporary plu...

Embodiment 2

[0045] Embodiment 2, the water-soluble fracturing acidification temporary plugging agent of the present invention contains three components of bone glue, sulfonated pitch and guar gum, wherein the weight ratio of the three components is: bone glue: sulfonated pitch: guar gum is 5.5:1.5:2.

[0046] The preparation method adopted is: measure 55Kg of water, heat it and keep it at 70°C, add 55Kg of bone glue, and stir while adding, so that the bone glue is completely dissolved. After the temperature drops to 40°C, add 15Kg of sulfonated asphalt, while adding Stir evenly, then add 20Kg of guar gum, stir vigorously to mix the components evenly, pour it on the container, spread it into a cake shape with a thickness of about 3mm, dry it naturally, crush it with a pulverizer, and sieve it to select the particle size diameter 3-6mm is used as a temporary plugging agent for finished products.

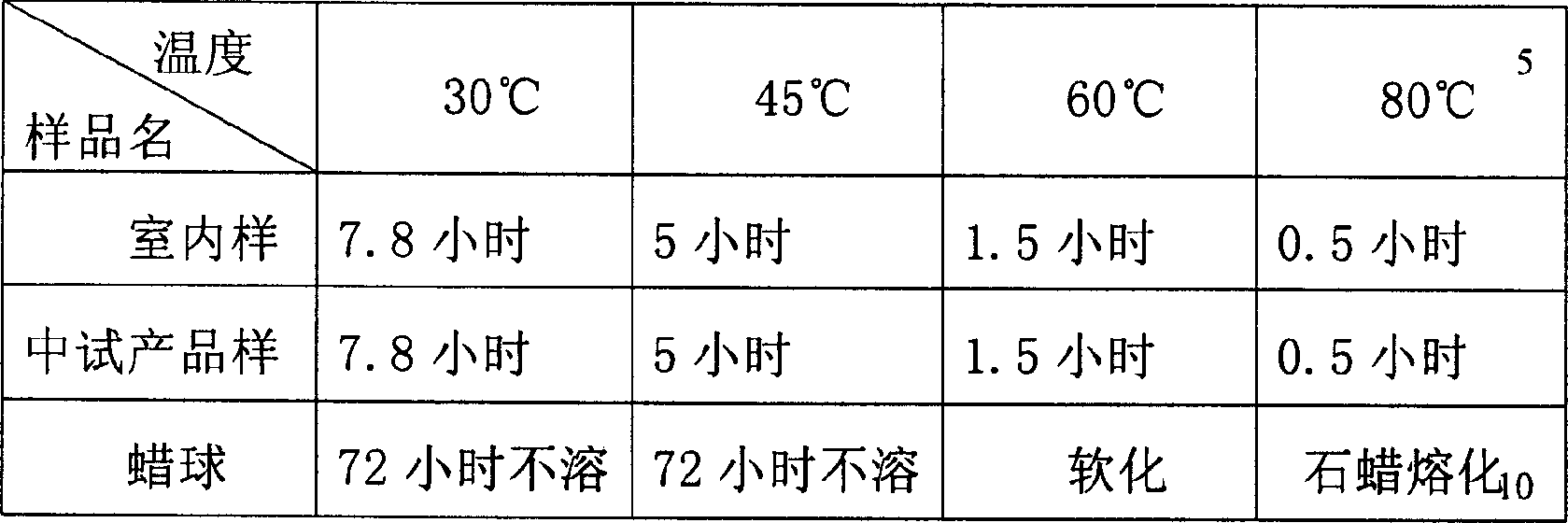

[0047] (1) Solubility experiment: test the dissolution rate of samples at different temperatu...

Embodiment 3

[0070] Embodiment 3, the water-soluble fracturing acidification temporary plugging agent of the present invention, it contains three kinds of components of bone glue, sulfonated pitch and guar gum, wherein the weight ratio of three kinds of components is: bone glue: sulfonated pitch: guar gum is 6:2.5:1.5.

[0071] The preparation method adopted is: measure 60Kg of water, heat it and keep it at 80°C, add 60Kg of bone glue, and stir while adding, so that the bone glue is completely dissolved. After the temperature drops to 50°C, add 25Kg of sulfonated asphalt, while adding Stir evenly, then add 15Kg of guar gum, stir vigorously to mix the components evenly, pour it on the container, spread it into a cake shape with a thickness of about 3mm, dry it naturally, crush it with a pulverizer, and sieve it to select the particle size diameter 3-6mm is used as a temporary plugging agent for finished products.

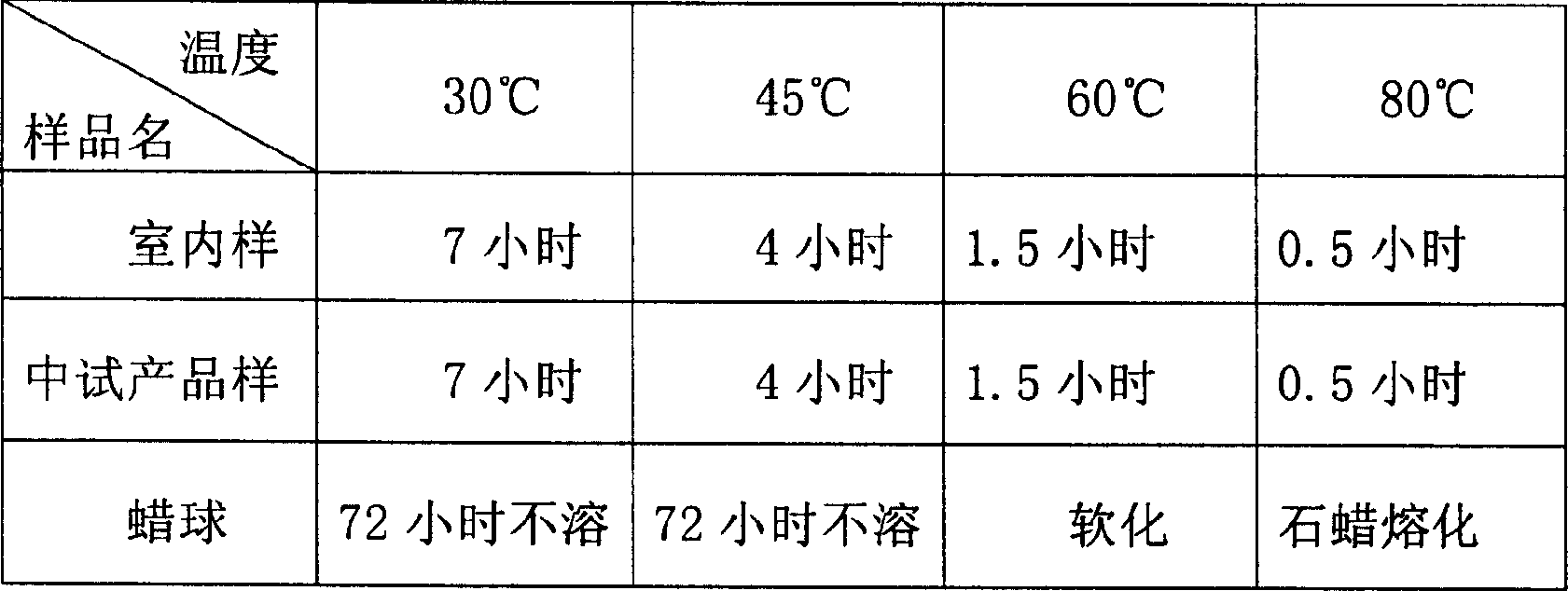

[0072] The temporary plugging agent prepared in the above-mentioned Example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com