Liquid nitrogen gasification scanning calorimetry method and liquid nitrogen gasification calorimeter

A scanning calorimetry and liquid nitrogen technology, applied in the field of material thermal property measurement, can solve the problems of high liquid nitrogen consumption, troublesome, time-consuming measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

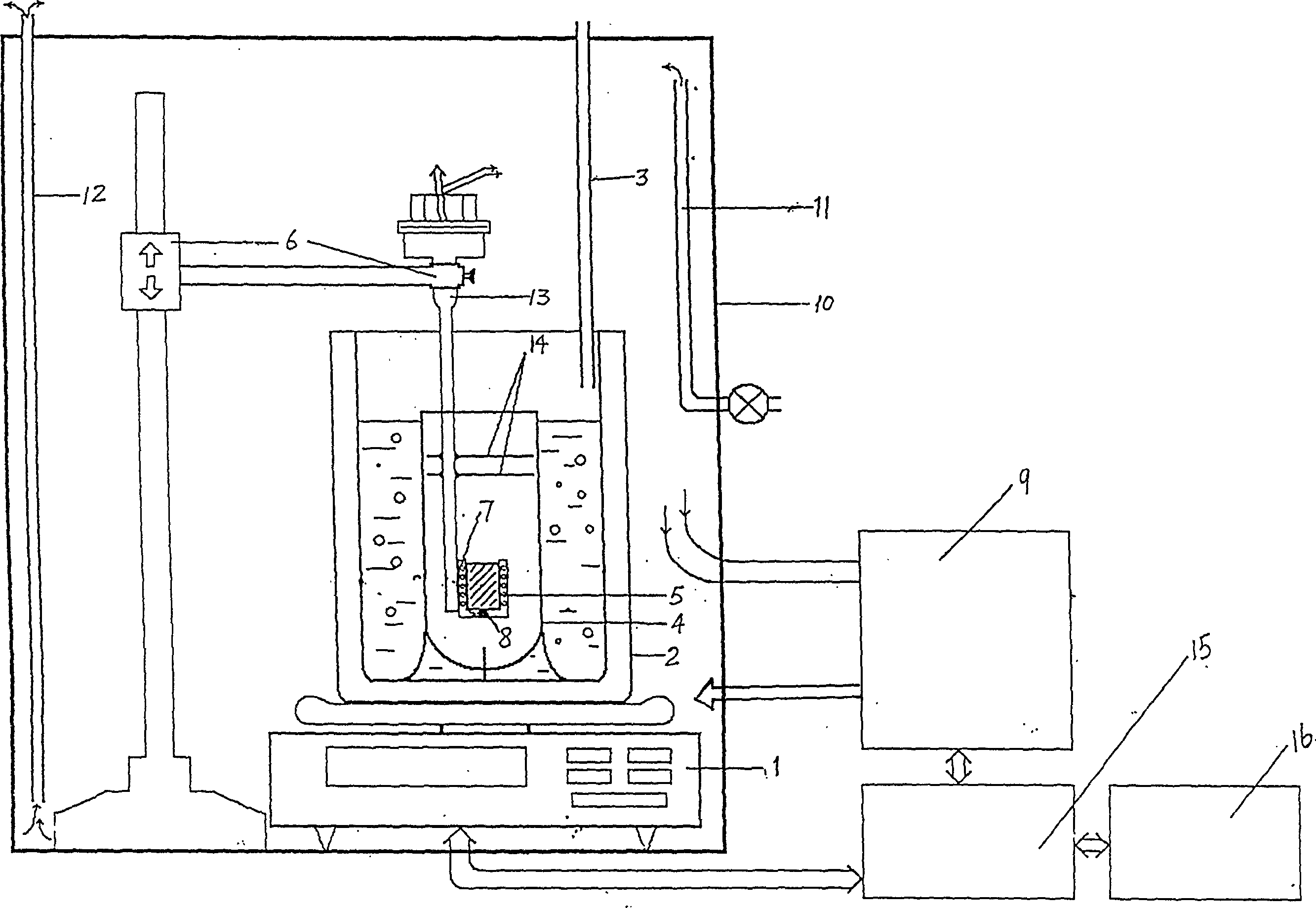

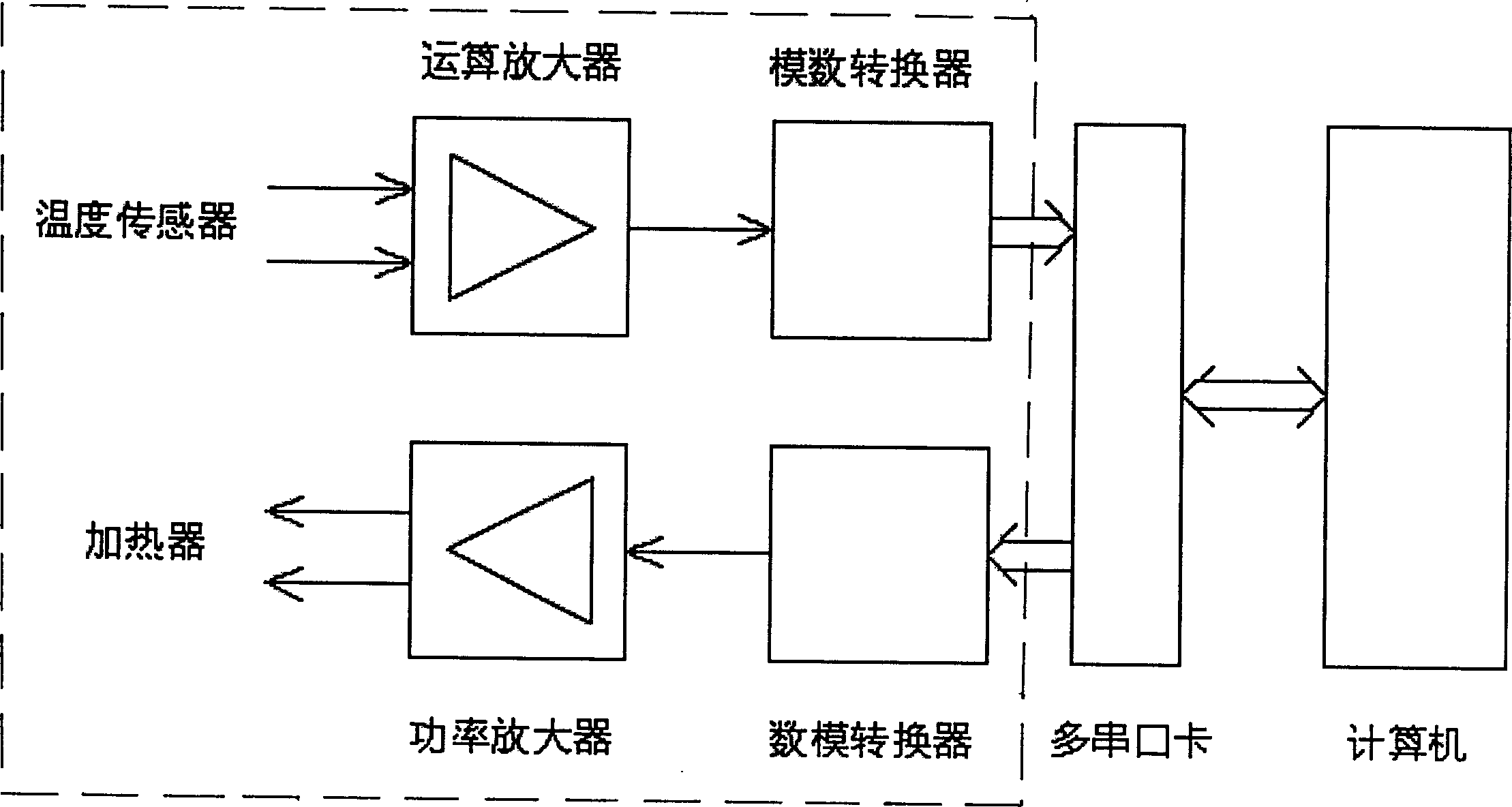

[0120] Embodiment 1, liquid nitrogen gasification scanning calorimeter:

[0121] The calorimeter includes an electronic balance 1, a vacuum insulation container 2, a liquid nitrogen addition tube 3, a heat conduction container 4, a sample chamber 5 and a suspension lifting mechanism 6 for the sample chamber. The electronic balance 1 is 500g / 1mg grade; the vacuum insulation container 2 is placed on the weighing pan of the electronic balance, the vacuum insulation container 2 has an inner diameter of 60mm, a depth of 160mm, and a weight of 206.873g, which is Cr 1 Ni 18 Ti 9 Made of stainless steel; the heat conduction container 4 is placed in the vacuum insulation container 2, the heat conduction container 4 is made of copper, the inner diameter is 20mm, the depth is 60mm, and the wall thickness is 0.2mm; the sample chamber 5 is a copper cylinder, the inner diameter of the outer bladder is 13.6mm, and the height is 13.5mm , wall thickness 0.3mm, inner diameter of liner 12.5mm,...

Embodiment 2

[0123] Embodiment 2, using the liquid nitrogen gasification scanning calorimeter described in Example 1, under the condition of no power compensation, adopt the liquid nitrogen gasification scanning calorimetry to test the oxygen-free copper sample (mass 10.99g, diameter 12.5mm, height 10mm cylinder) for specific heat capacity measurements in the temperature range from -190°C to 200°C:

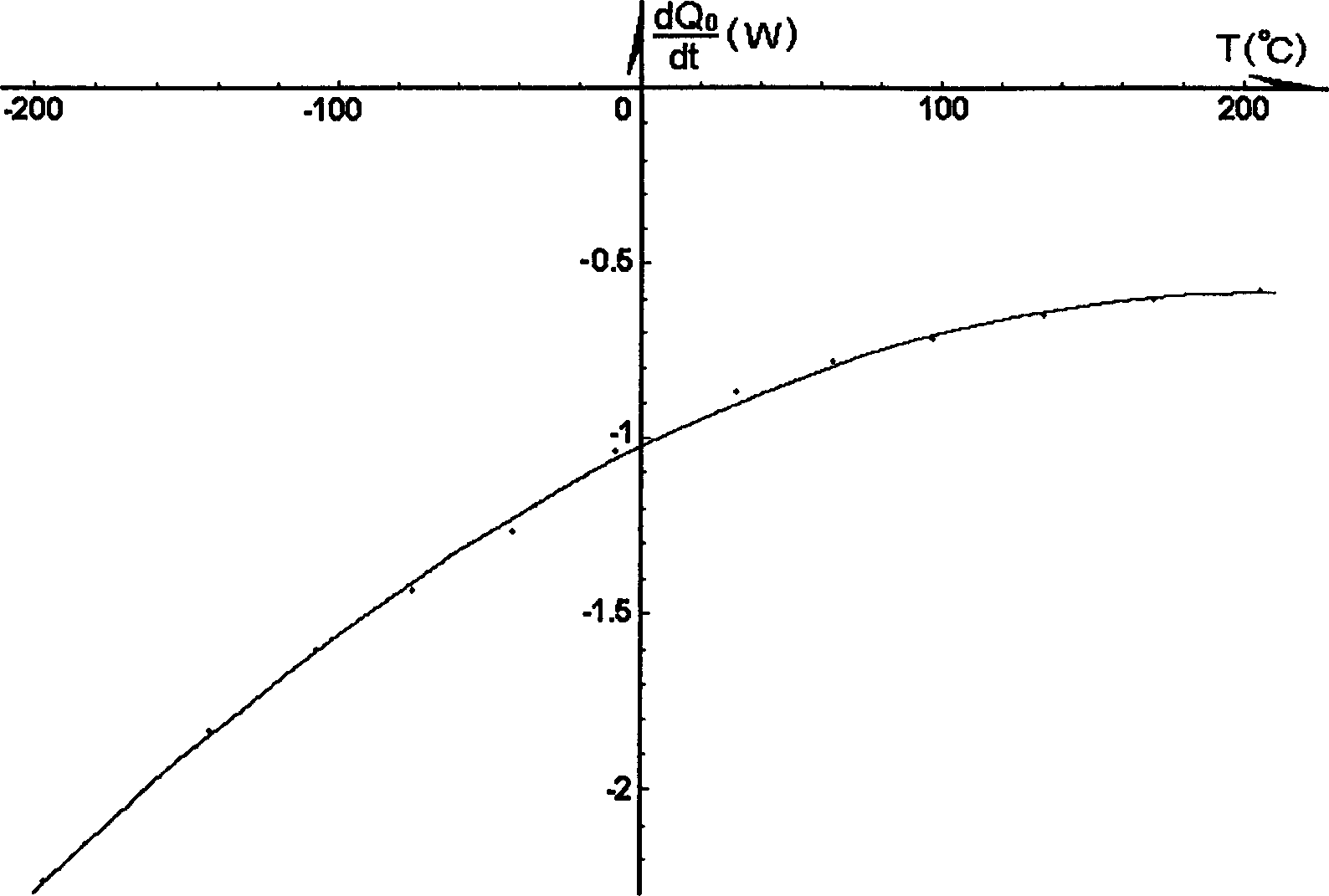

[0124] Step 1. Determining the correction curve:

[0125] 1. Liquid nitrogen is injected into the vacuum insulation container, so that the liquid nitrogen surrounds the heat conduction container placed in the vacuum heat insulation container, but does not enter the heat conduction container, and the sample chamber is suspended in the heat conduction container; the total mass of liquid nitrogen injected is 112g. At this time, the liquid nitrogen The nitrogen surface is about 5mm away from the upper edge of the heat absorber. Before being placed in the sample chamber, the natural gasification r...

Embodiment 3

[0136] Embodiment 3, using the liquid nitrogen vaporization scanning calorimeter described in Example 1, under the condition of no power compensation, adopt the liquid nitrogen vaporization scanning calorimetry to test the gadolinium sample (quality 9.682g, which is 12.5mm in diameter and 10mm in height) Cylinders, purity better than 99.9%) for specific heat capacity measurements over a temperature range of -190°C to 200°C. Measuring method and process are basically the same as embodiment 2, measure and obtain sample temperature change rate-temperature characteristic curve (such as Figure 10 shown), liquid nitrogen mass change rate-temperature characteristic curve (such as Figure 11 shown). Figure 12 The dot in the middle is the specific heat capacity-temperature response curve of the gadolinium sample under the condition of free cooling obtained according to formula (3), and the relevant data shown in the thin line are extracted from Physical Review Letters, Vol.

[0137...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystallization point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com