Method of producing resin molded product

A manufacturing method and resin mold technology, applied in the field of resin molding, the manufacturing field of resin molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

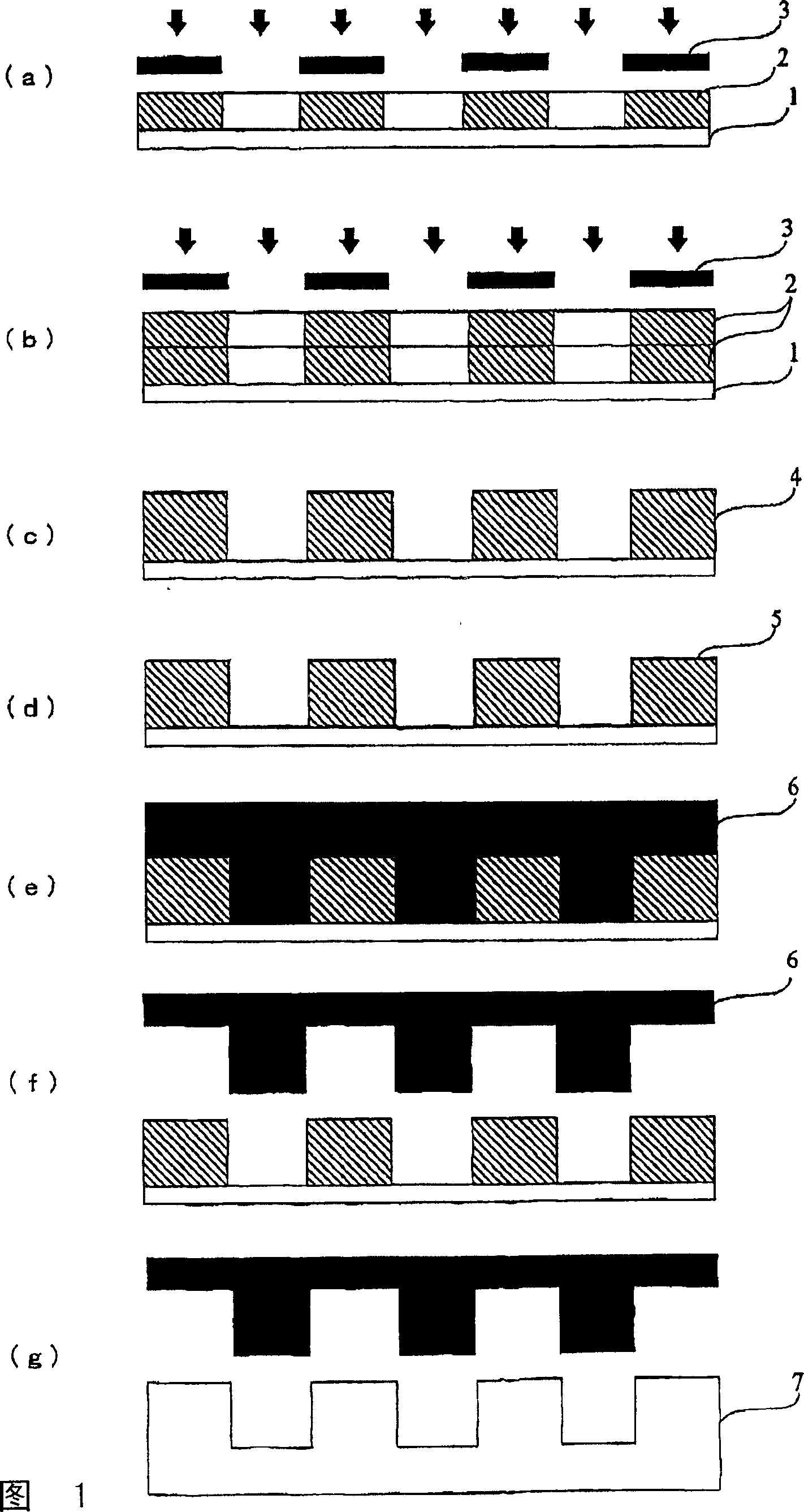

Method used

Image

Examples

Embodiment 1

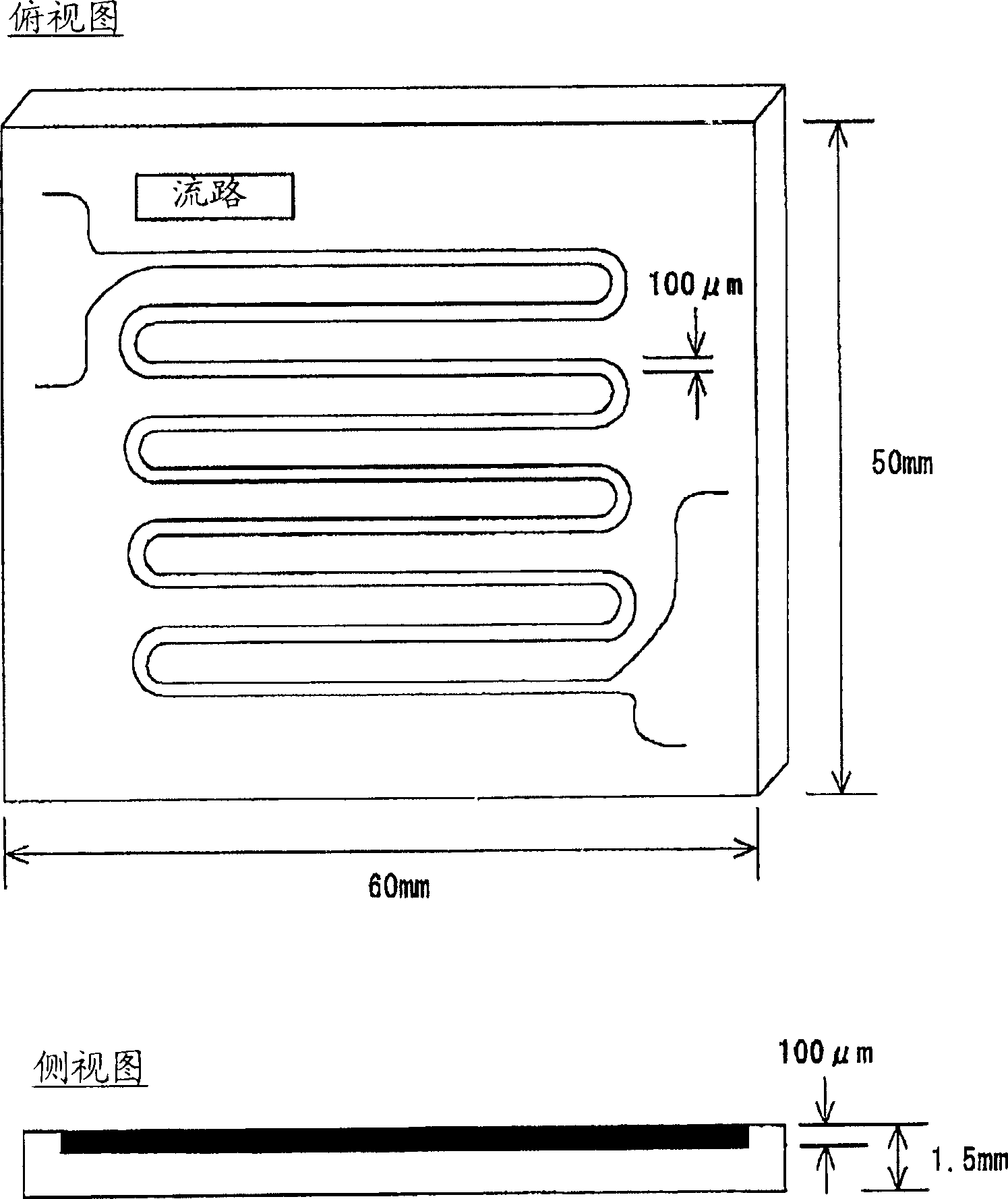

[0152] «Example 1» [Manufacture of a molded article having a flow path]

[0153] The resist layer forming step was repeated 3 times according to the method for forming a molded article shown in FIG. figure 2 A molded product having a flow path of 100 μm in width and 100 μm in depth was produced on a substrate of 60 mm in width by 50 mm in length and 1.5 mm in thickness as shown.

Embodiment 2

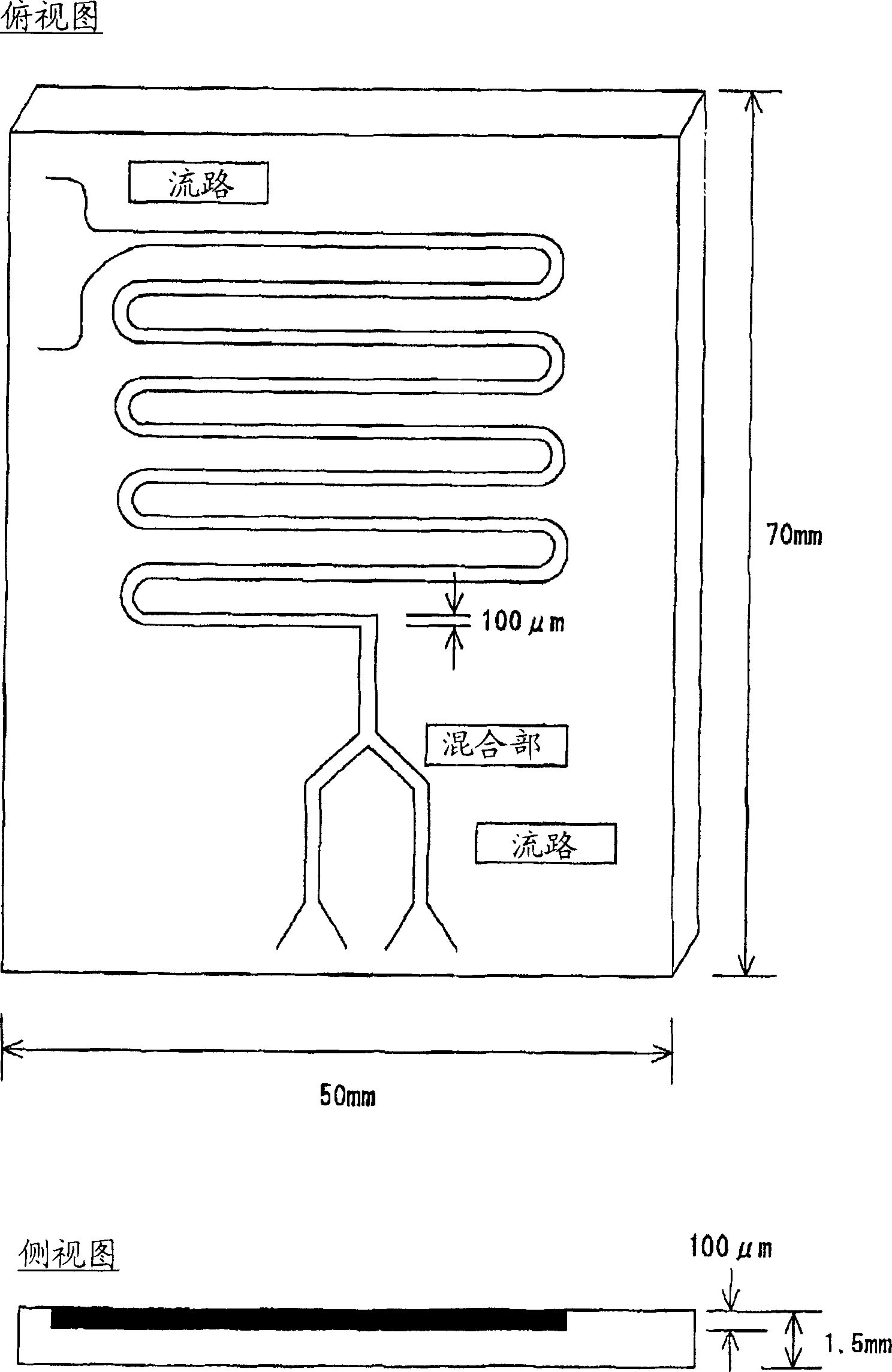

[0154] «Example 2» [Manufacture of a molded article having a flow path and a mixing portion]

[0155] The resist layer forming step was repeated 3 times according to the method for forming a molded article shown in FIG. image 3 A molded product having a flow path and a mixing portion having a width of 100 μm and a depth of 100 μm was produced on a substrate of 50 mm in width x 70 mm in height and 1.5 mm in thickness as shown.

Embodiment 3

[0156] «Example 3» [Manufacture of a molded article having a container]

[0157] The resist layer forming step was repeated 7 times according to the method of forming a molded article shown in FIG. Figure 4 A molded product having a container with a width of 200 μm and a depth of 250 μm was produced on a substrate of 60 mm in width×40 mm in height and 1.5 mm in thickness as shown.

[0158] The molded article obtained by the present invention can achieve high dimensional accuracy and the like compared with conventional molded articles. Furthermore, since such a molded product can be manufactured inexpensively while achieving precision, it is effective in being able to utilize the merits of efforts to control manufacturing costs and to use it in mass production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com