Functional foodstuff of cassia seed and preparation method

A functional food, cassia seed technology, applied in food preparation, food science, pharmaceutical formula, etc., can solve the problems of waste of raw materials, few active ingredients, and insignificant health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

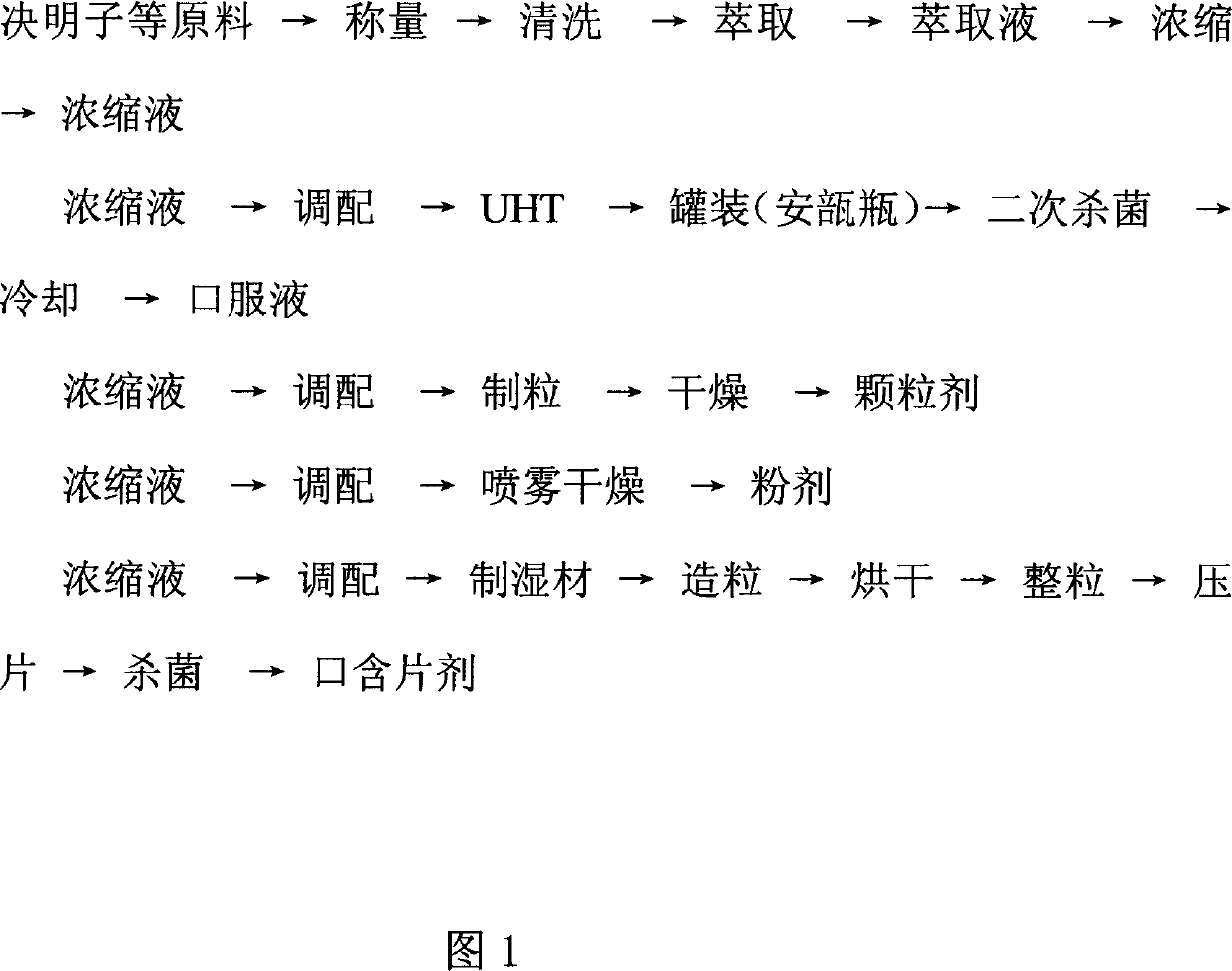

Method used

Image

Examples

Embodiment 1

[0015] Weigh 25kg of cassia seeds, 20kg of raw hawthorn, 2kg of chrysanthemum, 2kg of licorice, 15kg of peach kernels, and 25kg of jujube kernels, put them into an extraction tank, add 4000L of water, heat and reflux at 100°C for 30min, and filter out the extract when cooled to 80°C Add 2000L of water for extraction, heat to reflux for 30min, pour out the extract at 80°C, and combine the secondary extracts. The extract was concentrated under reduced pressure, the concentration temperature was 85°C, the vacuum degree was 0.09MPa, and it was concentrated to 1 / 4 of the original volume to stop the concentration.

[0016] Measure 1000L of the concentrated solution, add 200g of aspartame, 20kg of citric acid, and 10Kg of cyclodextrin into it. Sterilize for the first time (100°C, 30min), cool and pack. The oral liquid is reddish-brown in color, transparent, and has a sweet and sour taste.

[0017] Measure 1000L of the concentrated solution, add it to the double-effect concentrator ...

Embodiment 2

[0020] Weigh 3500g of cassia seed, 2400g of raw hawthorn, 600g of chrysanthemum, 600g of licorice, 2500g of peach kernel, 1500g of jujube kernel, put them into the extraction tank, add 400L of water, heat and reflux at 100°C for 30min, pour out the extract when cooled to 80°C, and pour out the extract for the second time Add 200L of water for extraction, heat to reflux for 30min, pour out the extract at 80°C, and combine the secondary extracts. The extract was concentrated under reduced pressure, the concentration temperature was 85°C, the vacuum degree was 0.09MPa, and it was concentrated to 1 / 4 of the original volume to stop the concentration. Prepare oral liquid, granule with the method for embodiment 1.

[0021] Weigh 50% of white sugar powder, 10% of maltodextrin, 28% of soluble starch, 10-% of glucose powder, 1.2% of citric acid, grind and mix the above materials evenly, pass through a 100-mesh sieve, and mix the concentrate with 70% ethanol in equal volume Add liquid a...

Embodiment 3

[0023] Weigh 3000g of cassia seed, 2200g of raw hawthorn, 400g of chrysanthemum, 400g of licorice, 2000g of peach kernel, 2000g of jujube kernel, put them into the extraction tank, add 400L of water, heat and reflux at 100°C for 30min, pour out the extract when cooled to 80°C, and pour out the extract for the second time Add 200L of water for extraction, heat to reflux for 30min, pour out the extract at 80°C, and combine the secondary extracts. The extract was concentrated under reduced pressure, the concentration temperature was 85°C, the vacuum degree was 0.09MPa, and it was concentrated to 1 / 4 of the original volume to stop the concentration. Prepare oral liquid, granule with the method for embodiment 1.

[0024] Weigh 45% of white sugar powder, 15% of maltodextrin, 23% of soluble starch, 15% of glucose powder, and 1% of citric acid. The above raw materials are crushed and mixed evenly, and then passed through a 100-mesh sieve. The concentrated solution and 70% ethanol are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com