Biological polysaccharide macromolecule magnetic microsphere and preparation method

A technology of polymer magnetism and biological polysaccharides, which is applied in the field of biopolysaccharide polymer magnetic microspheres and its preparation, and can solve unrelated problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

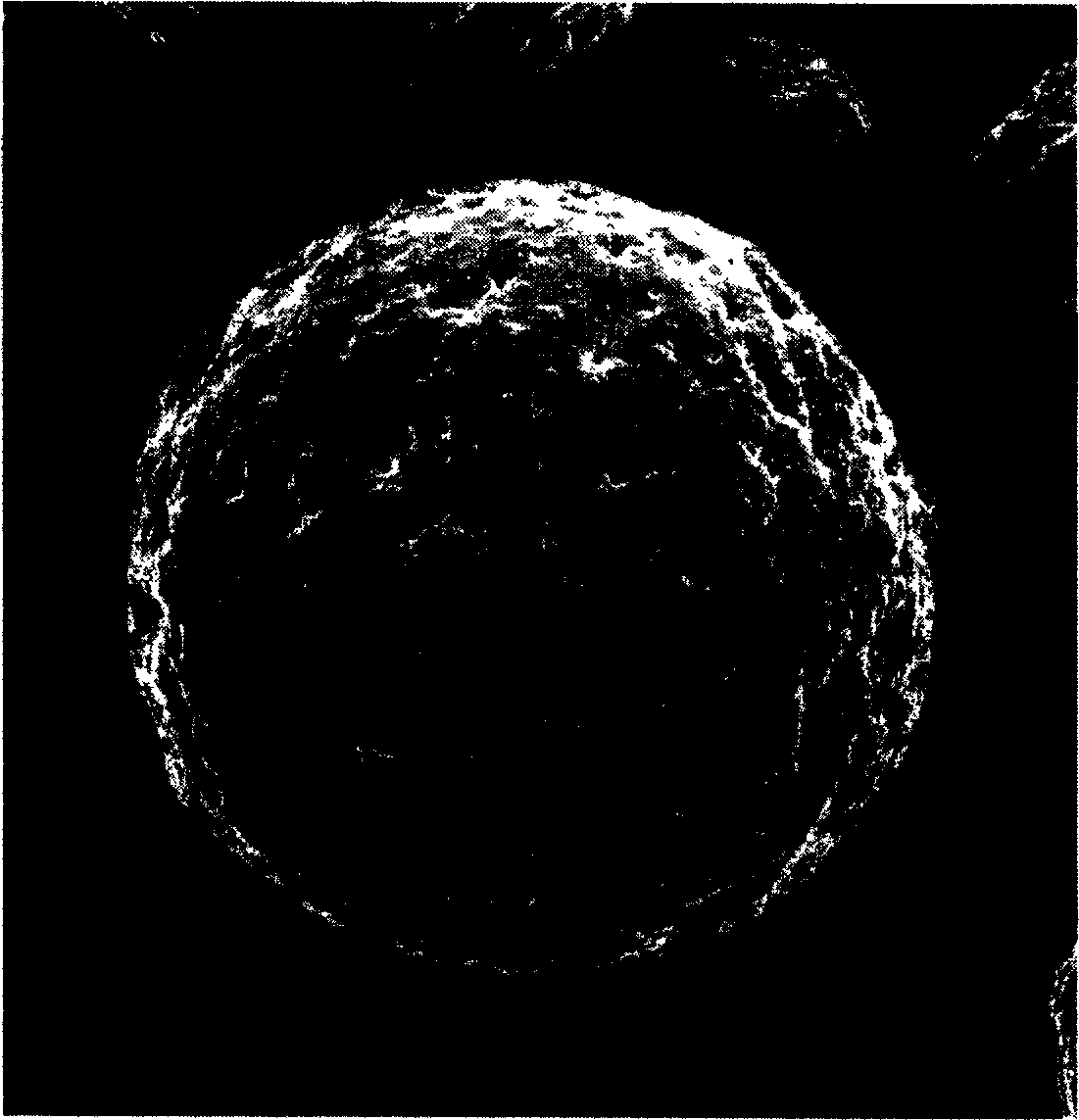

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation of tamarind jelly magnetic microspheres,

[0018] Step 1: Prepare 34.8% FeSO 4 ·7H 2 O in water, 54.1% FeCl 3 ·6H 2 O aqueous solution, 36.0% NaOH aqueous solution;

[0019] Step 2: Mix the ferrous salt solution and the ferric salt solution (V / V) 4:5, stir,

[0020] Step 3: Heat up to 55°C, add 5 parts (V / V) of alkali solution, add PEG10000 3.6% (W / V) after reacting for 30 minutes;

[0021] Step 4: Heat up to 80°C and react for 30 minutes to stop the reaction, cool to room temperature, neutralize to neutral with hydrochloric acid, let stand, the supernatant is water-soluble magnetic fluid;

[0022] Step 5: In 50ml of 1.0% anhydrous sulfanilic acid aqueous solution, add 1ml of water-soluble magnetic fluid, 0.5g of tamarind gum, react at room temperature for 2hr, add organic paraffin, ethyl acetate, span-80, at 500rpm / Stir for 20min at a speed of min, slowly add 3ml of formaldehyde dropwise, continue to stir for 1hr, pour off the super...

Embodiment 2

[0023] Example 2: Preparation of Artemisia Gum Magnetic Microspheres

[0024] In step 5, replace 0.5g tamarind gum with 0.40g Artemisia gum, and the types, proportions and preparation methods of other reagents are the same as those described in Example 1, to obtain Artemisia gum magnetic microspheres, and the magnetic susceptibility of Artemisia gum magnetic microspheres 1.726emu / g.

Embodiment 3

[0025] Embodiment 3: Preparation of xanthan gum magnetic microspheres

[0026] Replace 0.5g tamarind gum with 0.8g xanthan gum in step 5, the kind, proportioning and preparation method of other reagents are as described in embodiment 1, get xanthan gum magnetic microspheres, xanthan gum magnetic microspheres magnetized Rate 1.393emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Magnetic susceptibility | aaaaa | aaaaa |

| Magnetic susceptibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com