Method for nonlinear quantitative non-destructive inspection of bonding interface cohesive force using contact sound

A non-destructive testing and adhesion technology, which is used in material analysis, measuring devices, and instruments using sonic/ultrasonic/infrasonic waves. It can solve problems such as material damage, inability to give quantitative values, and unconvincing test results. achieve high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

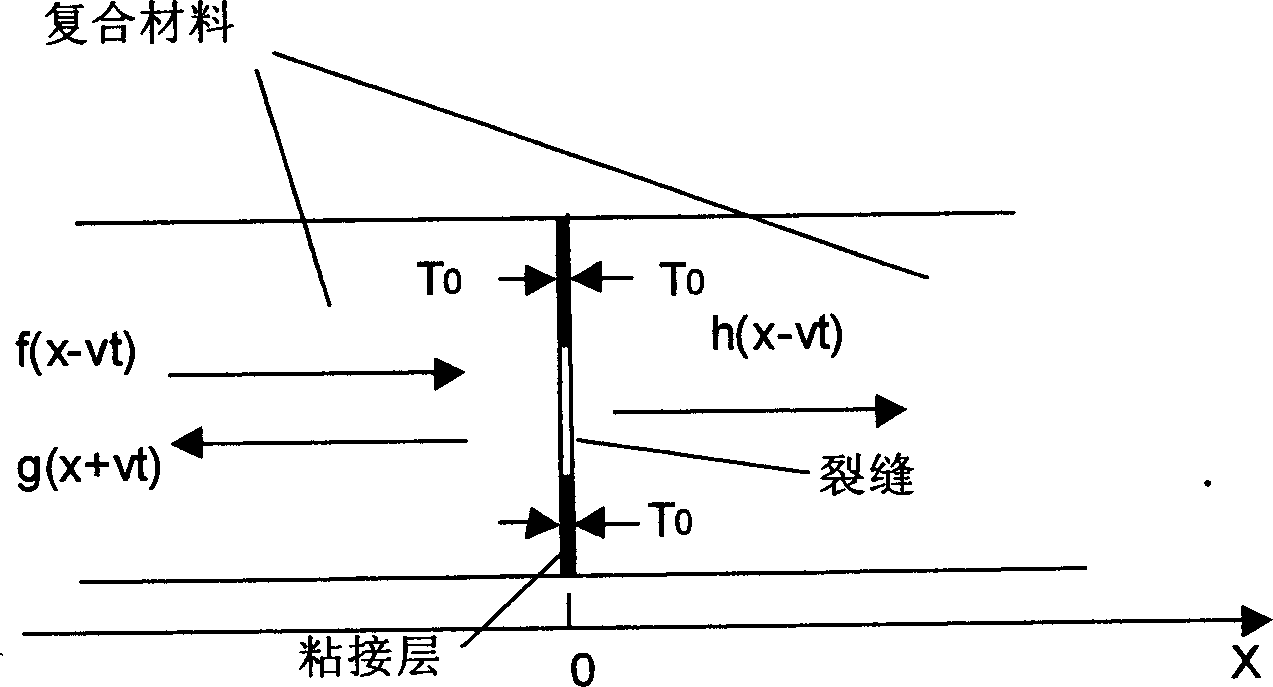

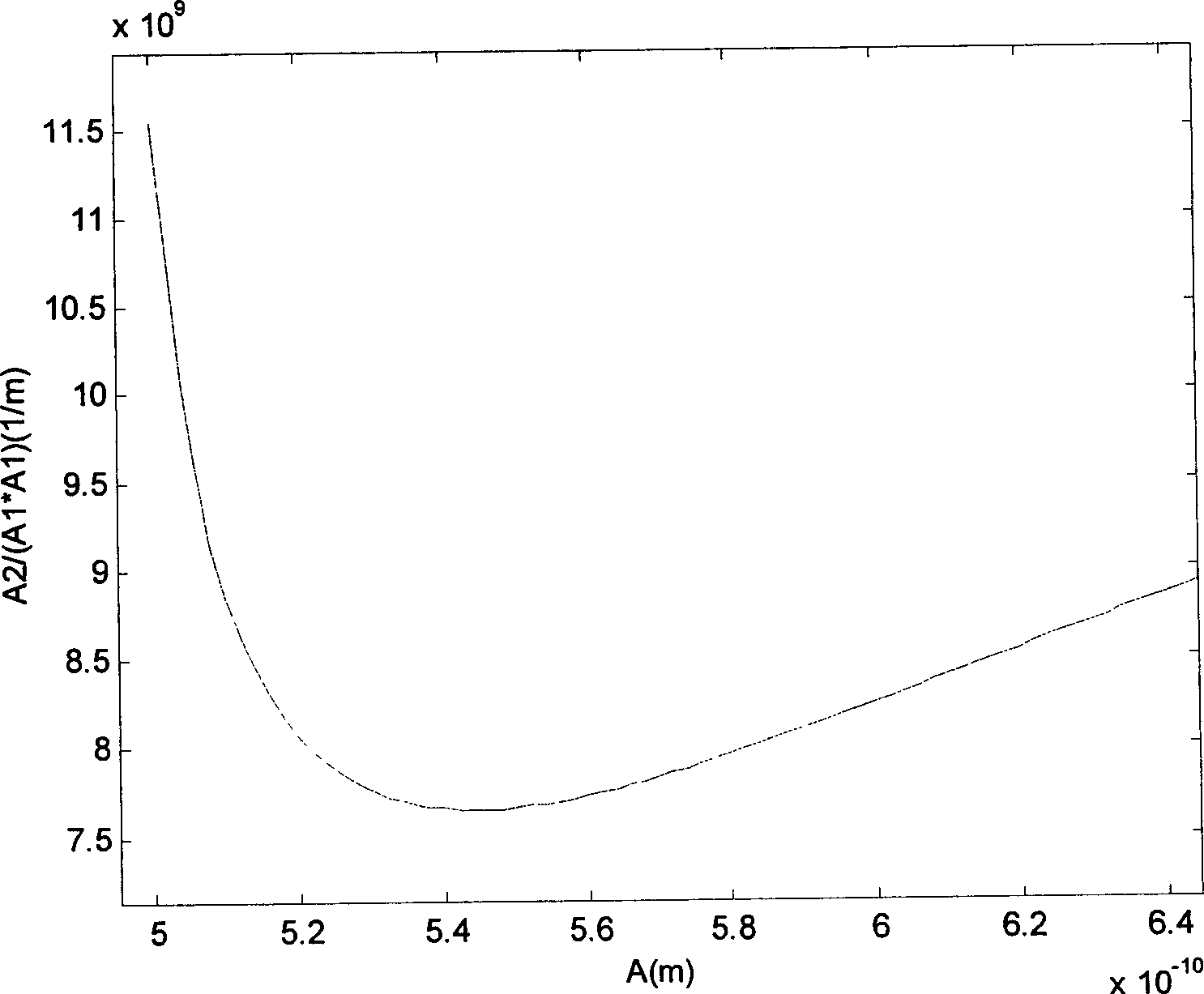

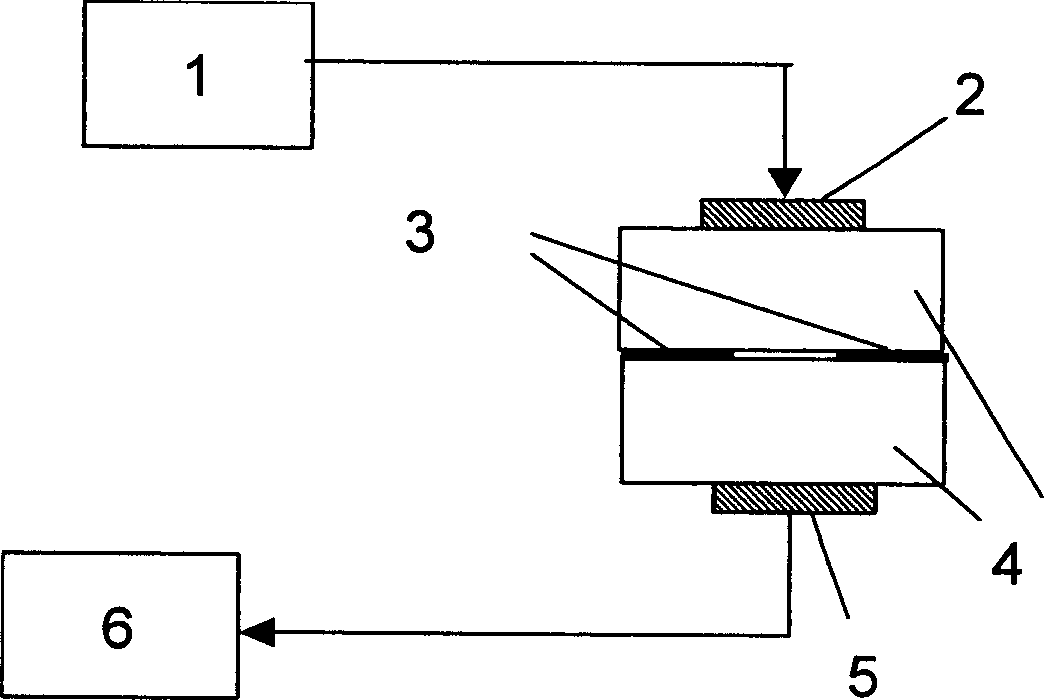

[0041] The composite material we choose is two pieces of glass, which are formed by bonding the two surfaces together with phenyl salicylate. The transducer uses a lithium niobate longitudinal wave transducer cut in the Z direction, with a fundamental frequency of 5 MHz and a second harmonic The frequency is 10 MHz, and the salicylic acid phenyl resin is pasted on the other two surfaces respectively. The base frequency signal generation system uses Agilent33250A signal generator, ENI 525LA power amplifier and low-pass filter (L6s60), which generates 5 MHz sine wave modulation pulse signal and adds it to the base frequency longitudinal wave transducer to generate base frequency The high-frequency longitudinal wave propagates through the adhesive layer in the glass to the second harmonic frequency transducer used for reception, and is converted into an electrical signal and displayed on the LeCroy LT262 digital oscilloscope. FFT is performed on the received signal on the digital ...

Embodiment 2

[0043] The composite material we choose is two pieces of aluminum, and the two surfaces are bonded together by means of external pressure. In fact, the external pressure is equivalent to the adhesive force, and the external pressure is 6.8 catties. The transducer uses a lithium niobate longitudinal wave transducer cut in the Z direction, with a fundamental frequency of 5 MHz and a second harmonic frequency of 10 MHz, which are pasted on the other two surfaces with phenyl salicylate. The base frequency signal generation system uses Agilent 33250A signal generator, ENI525LA power amplifier and low-pass filter (L6s60), which generates a 5 MHz sine wave modulation pulse signal and adds it to the base frequency longitudinal wave transducer to generate The high-frequency longitudinal wave propagates through the adhesive layer in the aluminum to the second harmonic frequency transducer used for reception, and converts it into an electrical signal and displays it on the LeCroy LT262 di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com