Optical fibre bending sensor for monitoring artificial cochlea electrode bending implantation and use thereof

A technology of cochlear implants and sensors, applied in ear therapy, etc., can solve the problems of high cost of cochlear implants, high cost of cochlear implants, and high requirements for implantation operations, and achieve the effects of simple structure, low cost, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

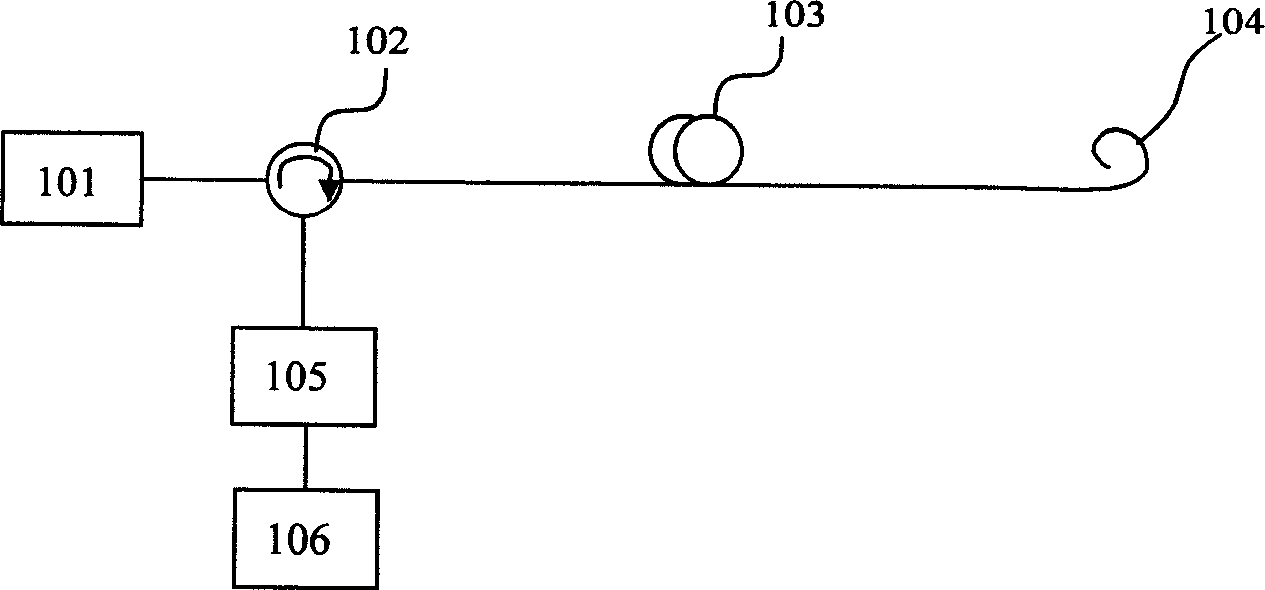

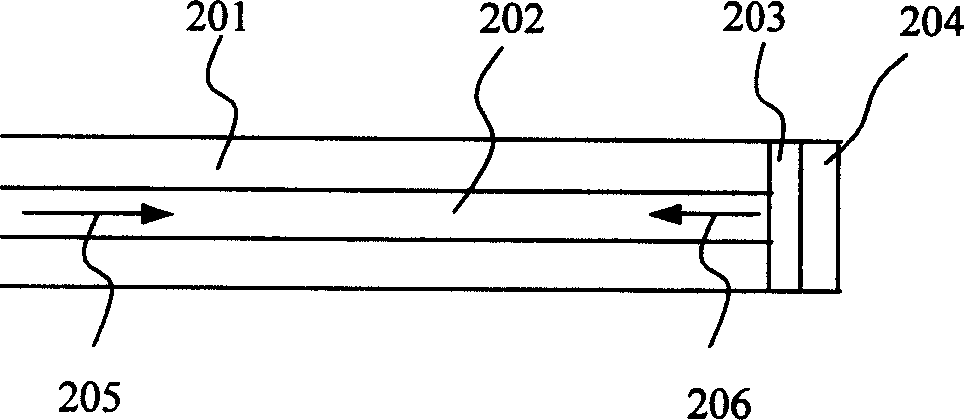

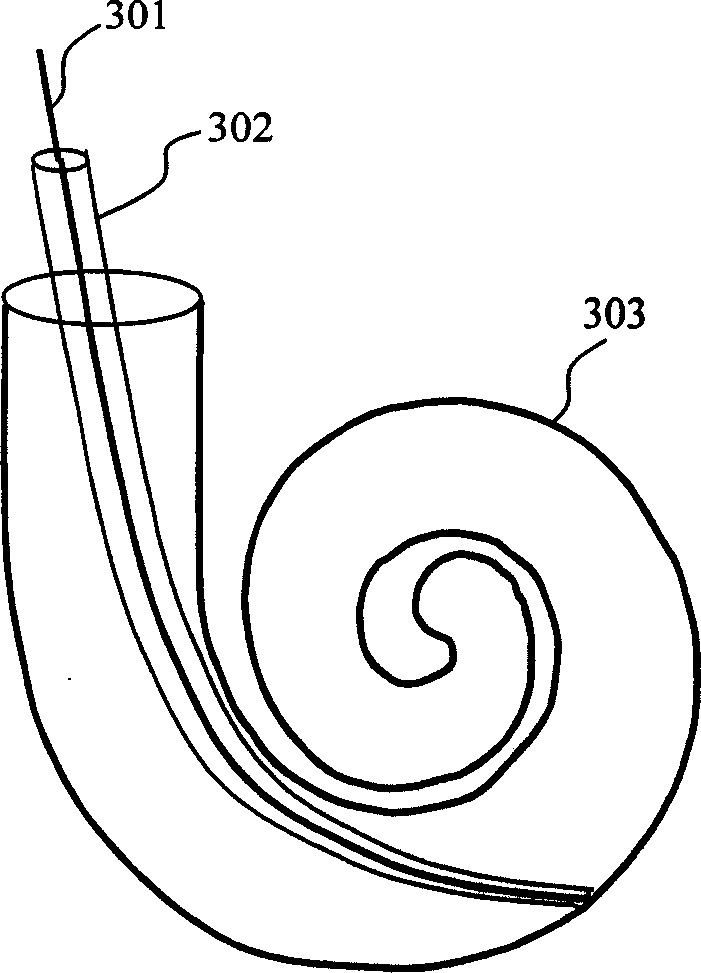

[0012] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. as attached figure 1 As shown, the optical fiber sensor probe is made of a silica optical fiber with a cladding (101) diameter of 80 microns and a core (102) diameter of 9 microns. The fiber is single-mode in the wavelength range from 980nm to 1600nm. After the fiber end face is cut with a special cutter, use a microscope to check that the end face is perpendicular to the fiber axis. Then a layer of aluminum reflective film 203 is evaporated on the end face of the optical fiber by vacuum coating technology. In order to prevent possible damage to the aluminum film during the use of the optical fiber sensor probe, a layer of silicon oxide film 204 is coated on the aluminum film as a protective film. Due to the use of 80 micron optical fiber, the possibility of the optical fiber being broken when the bending radius is small is red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com