Stalk feed stuff automatic production line

An automated production line, straw feed technology, applied in the fields of feed, food science, cutting equipment, etc., can solve the problems of only considering the mechanical processing process, high production cost, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

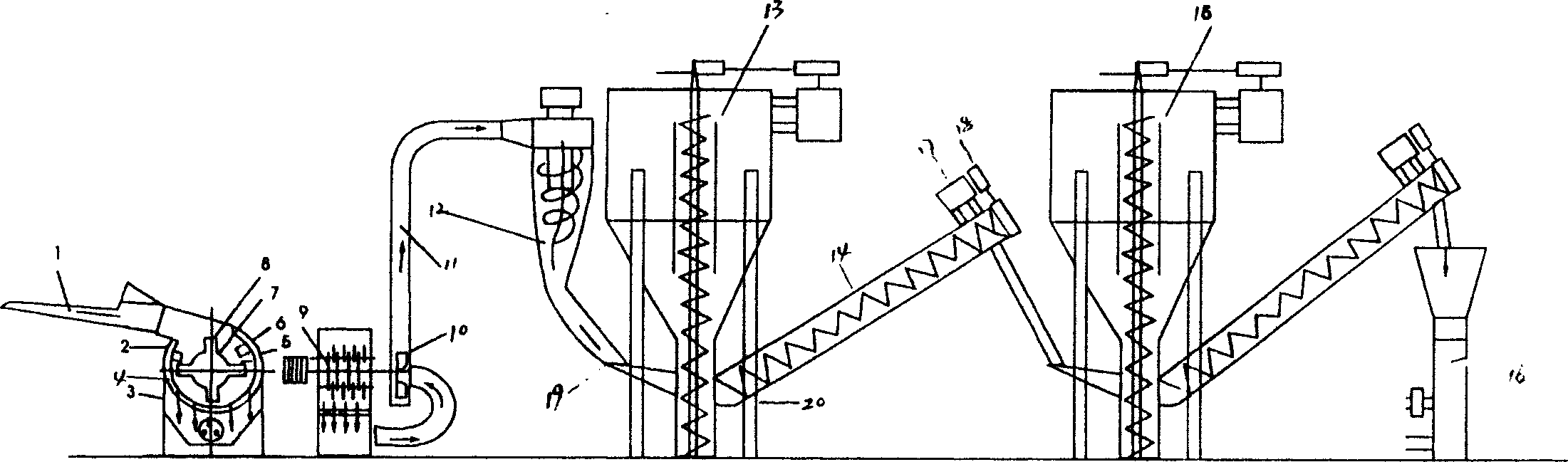

[0014] Example figure 1 As shown: the corn stalk processing machine is composed of an upper body 2 and a lower body 3, the feed hopper 1 is above the upper body 2, the hammer blade 8 is fixed on the rotor 7 through the hammer frame plate 9, and rotates rapidly under the drive of the power system. And make it rub against the tooth plate 5 fixed on the inner wall of the upper body 2, and the fixed knife 6 is also fixed on the inner wall of the upper body at the same time, the fixed knife 6 is connected with the tooth plate 5, and the fixed knife 6 is used to determine the hammer 8 and the tooth The distance between the plates 5. A sieve 4 is fixed on the lower part of the upper body 2, and the sieve 4 filters the crushed stalks, a blower fan 10 is fixed on the discharge port, a dust-proof device 12 is connected to the pipeline 11, and the lower port of the dust-proof device 12 is connected to the material tank. Feed inlet 19 links to each other. Crushed straw powder is mixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com