Device for controlling electric slag remelted atmosphere and method thereof

An electroslag remelting and atmosphere technology, which is applied in the field of electroslag remelting preparation by gas shielding technology, can solve the problem that the purity of remelted alloy ingots, the content of active elements are inconsistent, the purity of alloy ingots cannot meet the requirements for use, and the active elements Content deviation and other problems, to achieve the effect of ensuring uniformity, reducing oxygen content, and adequate protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

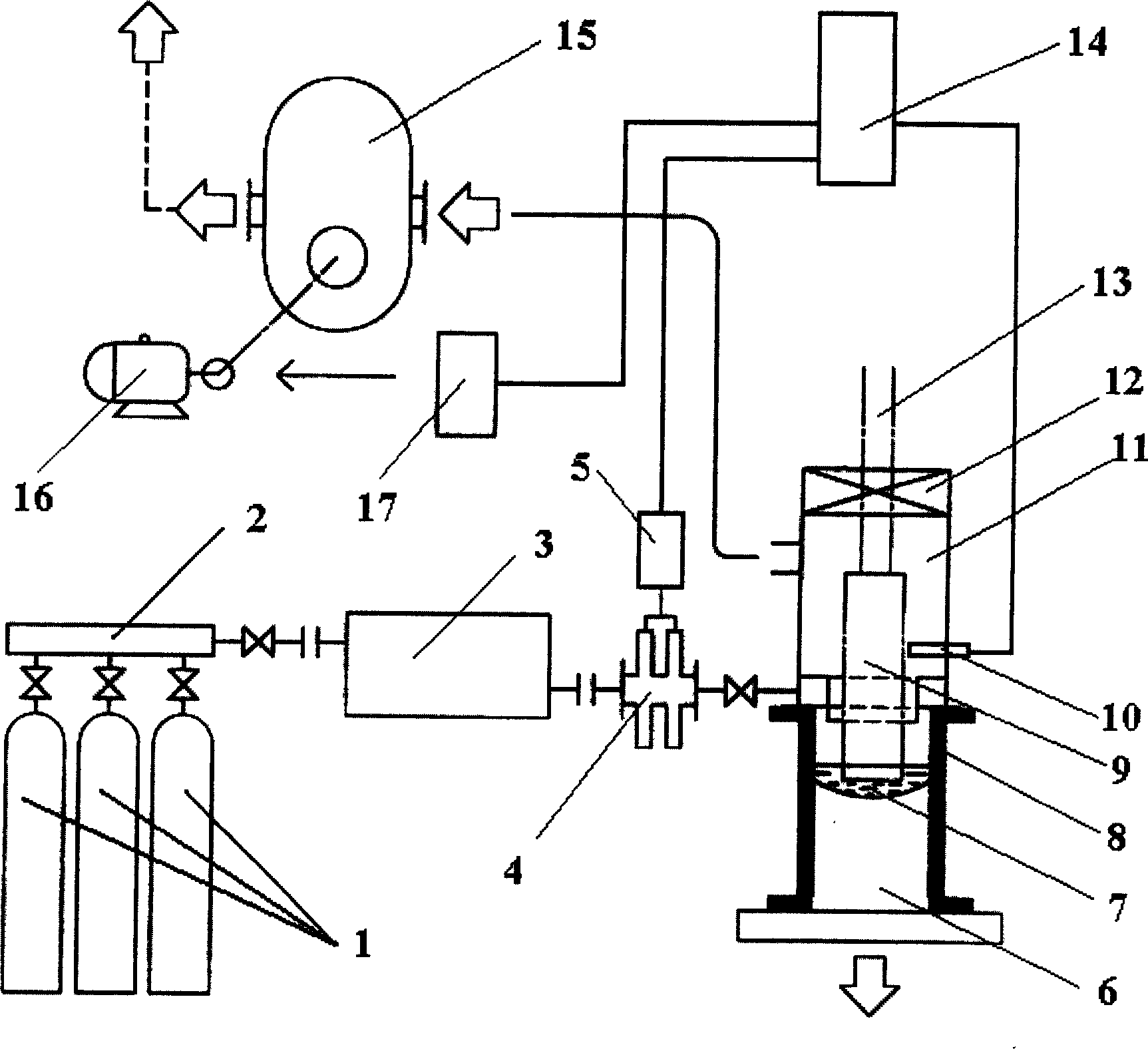

[0008] Using the device and method of the present invention, 10 heats of remelting and refining were carried out on a 380KVA electroslag furnace to prepare high-purity FGH95 alloy ingots, of which 4 heats remelted φ100×1200 consumable electrodes into φ160×470 alloy ingots (The furnace numbers are 1-4 in sequence), and the φ130×1000 consumable electrodes are remelted into alloy ingots of φ220×350 in 4 furnace times (the furnace numbers are 5-8 in sequence). Before the electroslag remelting process begins, the air in the sealed cover above the melting chamber is first pumped to a vacuum degree between 0.1pa-100pa, and the vacuum degree is controlled at 50pa-80pa, and then quickly filled with inert gas (argon), Control the pressure of the inert gas in the sealed cover above the melting chamber at 1.0-1.3×10 5 Pa, and then start the electroslag remelting process. During the whole smelting process, according to the oxygen partial pressure real-time measuring instrument in the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com