Method of selective laser crystallization and display panel manufactured by same method

A display panel and light-emitting display technology, applied to light sources, electric light sources, static indicators, etc., can solve problems such as pulse omission, ripple defects, and electrical inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

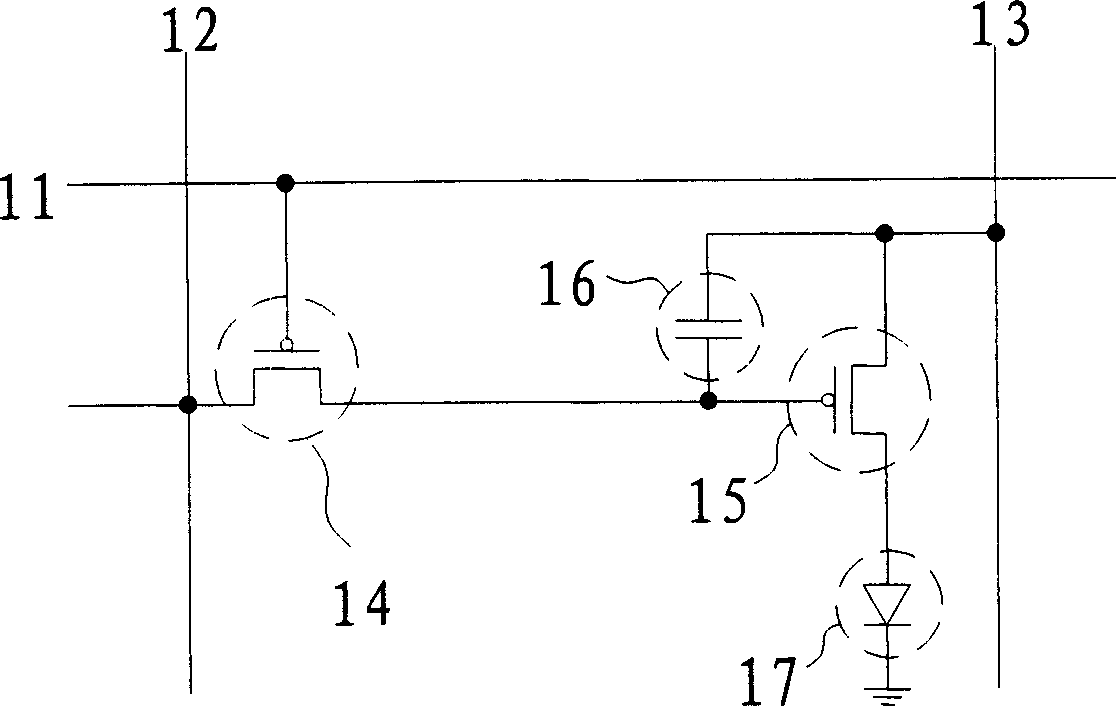

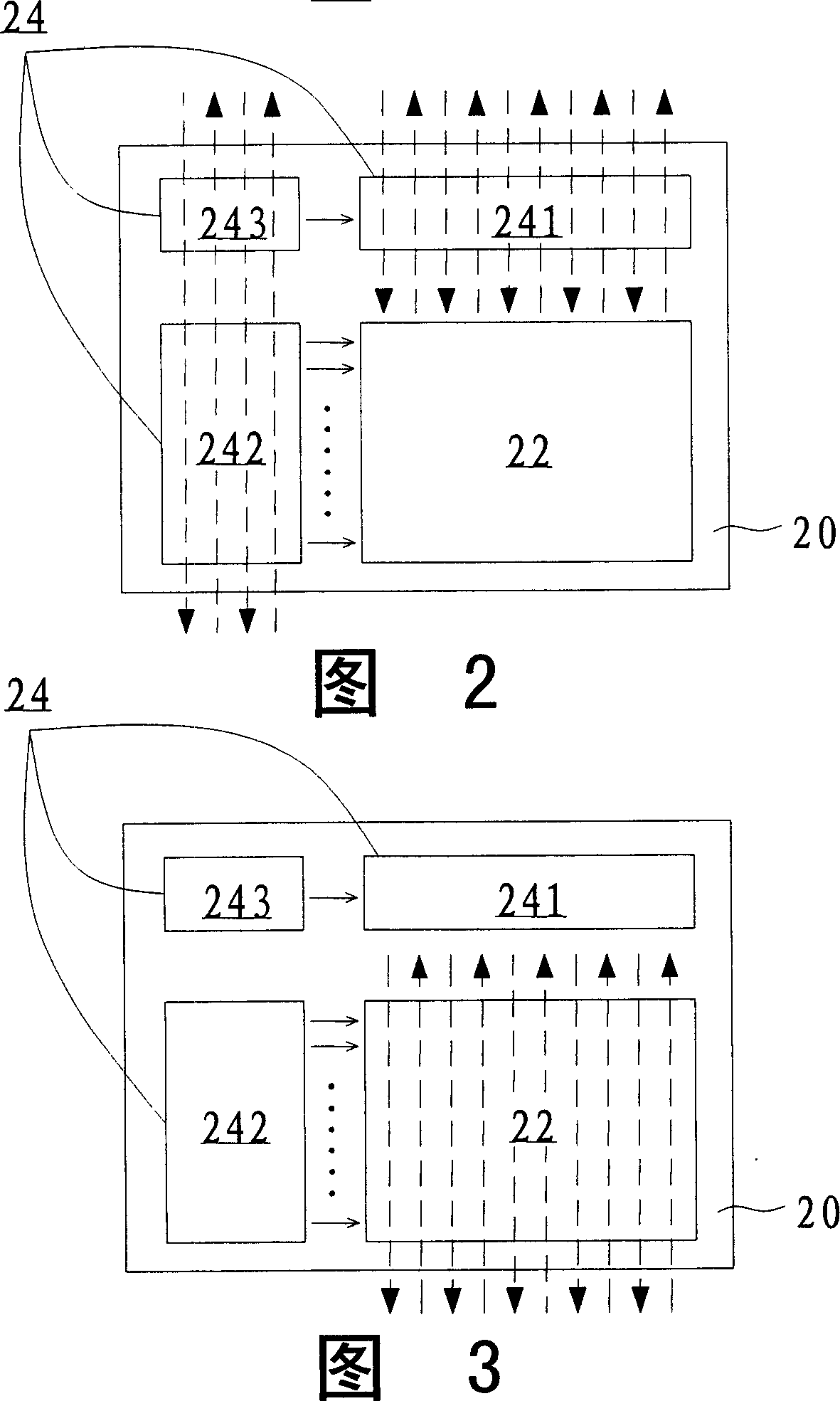

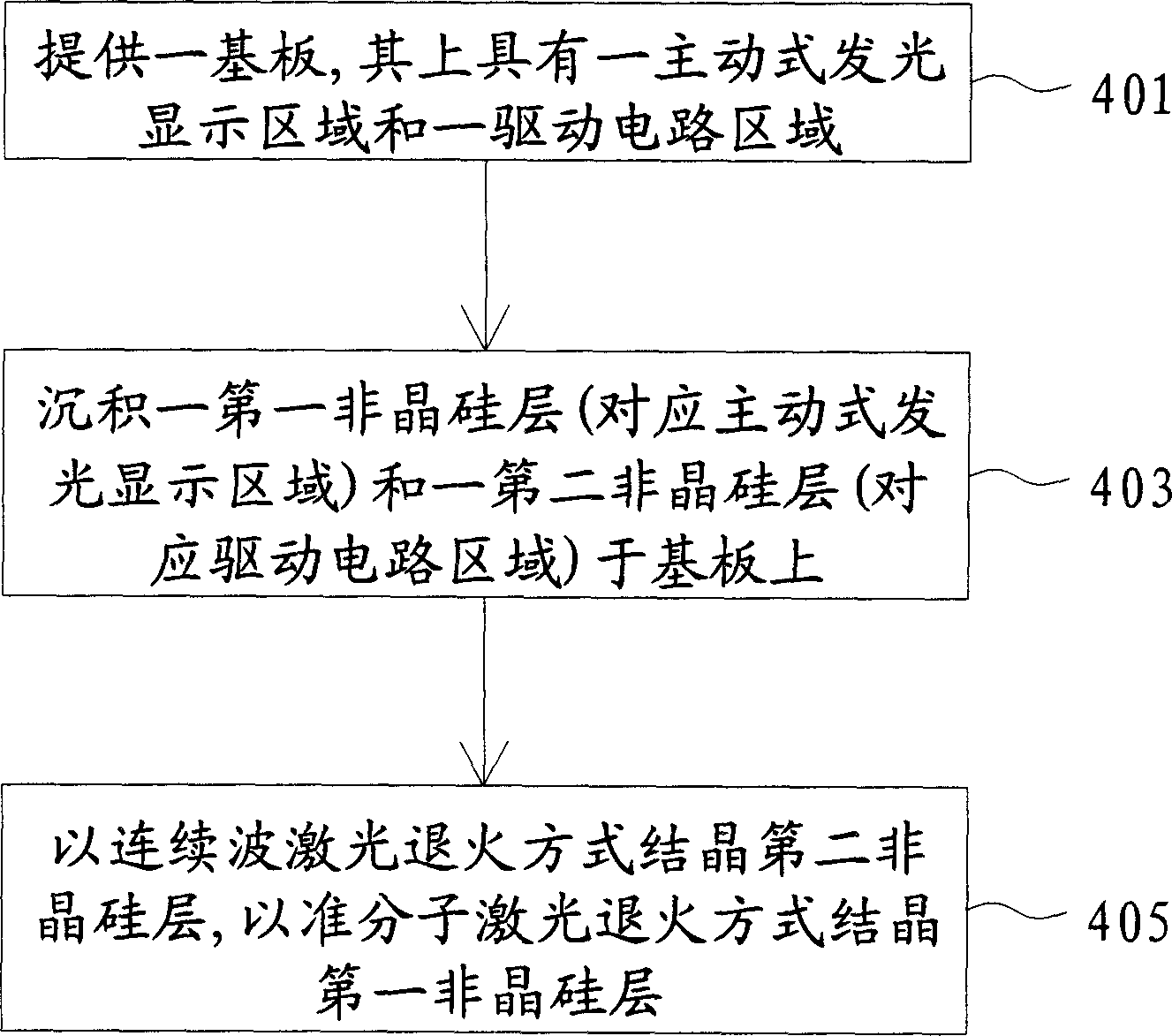

[0018] The present invention uses selective laser crystallization to crystallize the active light-emitting display area and the driving circuit area of the display panel in different ways, so that the production of the display panel can increase the throughput and the driving circuit area has good performance. Carrier mobility (Mobility). Wherein, the polysilicon in the driving circuit region is formed by continuous wave laser annealing (Continuous Wave Laser Annealing; CW Laser Annealing). As for the polysilicon in the active light-emitting display area, a method with a larger tempering distance and less overlap can be used, such as an Excimer Laser Annealing (ELA) method. In this way, the grain size of the polysilicon layer in the driving circuit area is larger, and the grain boundaries are more regular, so that the electrical performance of the carrier mobility is better; while the grain size of the polysilicon layer formed in the active light-emitting display area is sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com