Method for preparing polymer/inorganic nano composite material powder initiated by nano semiconductor

A nano-semiconductor, inorganic nano-technology, applied in the field of preparing polymer/inorganic nano-composite materials, can solve problems such as difficulty in agglomeration of nanoparticles, and achieve the effect of improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

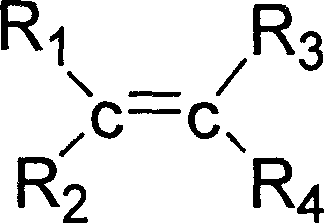

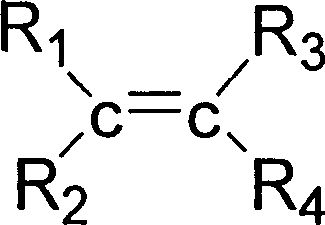

Method used

Image

Examples

Embodiment 1

[0038] Weigh the methyl methacrylate monomer, add deionized water to the mark, and prepare a monomer solution with a concentration of 12 g / L. The nano titanium dioxide (anatase type) powder is added to the methyl methacrylate aqueous solution, and the dispersion concentration of the titanium dioxide is 1 g / L. Then, an aqueous solution of copper nitrate was added to make the concentration of copper nitrate in the reaction system 0.01 mol / L. Continuously disperse with ultrasonic for 10 minutes to make the nanoparticles uniformly dispersed. The above-mentioned reaction liquid was added to the reactor, and after stirring for 10 minutes, the high-pressure mercury lamp placed outside the reactor was turned on, and the saturated copper sulfate aqueous solution was circulated through the jacket of the reactor. At the center of the reactor, the radiation intensity of 365 nm wavelength is 12 mw / cm 2 . The polymerization reaction lasted 300 minutes.

[0039] The product is a white powder pre...

Embodiment 2

[0041] The dosage of nanometer titanium dioxide is 0.2 g / L, and other conditions and experimental procedures are the same as in Example 1. Polymerize for 350 minutes. The product was a white precipitated powder, and the observation result of the electron microscope was the same as that of Example 1.

Embodiment 3

[0043] A 10 g / L pyrrole aqueous solution was prepared, and the dispersion concentration of nano-titanium dioxide was 1 g / L. The other conditions are the same as in Example 1. The reaction time is 280 minutes. Thirty minutes after the start of the reaction, a black precipitate appeared. Infrared spectroscopy analysis confirmed that the product contained polypyrrole and titanium dioxide. The electron microscope observed that the nano titanium dioxide particles were wrapped by the black polypyrrole produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com