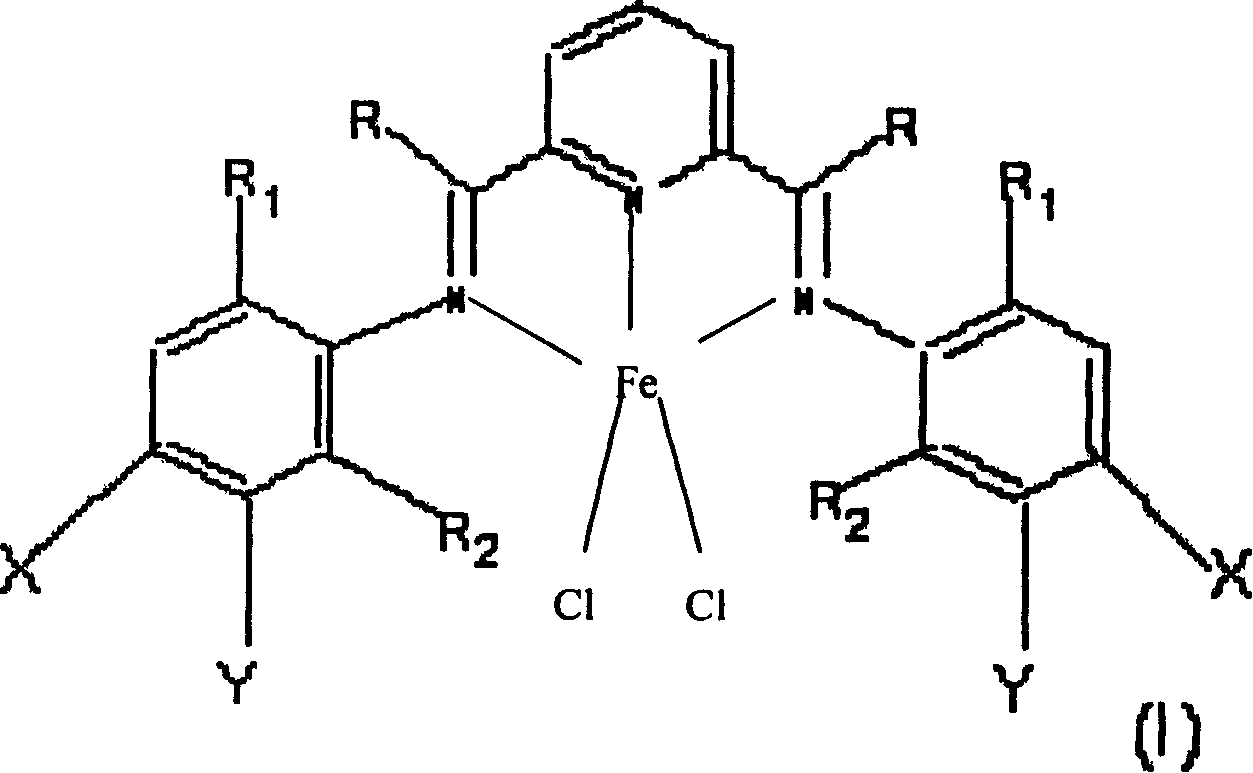

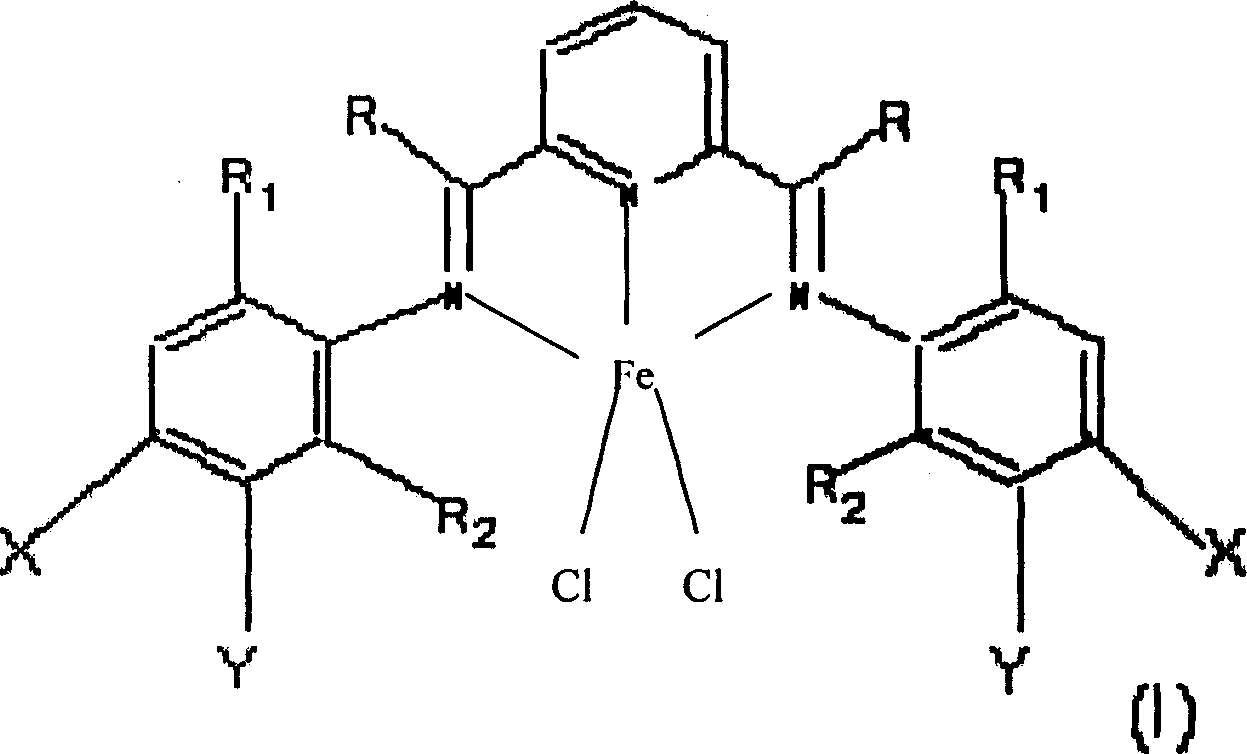

Method for preparing aluminosilicate supported irons post-transition metal ethylene polymerization catalyst

A late-transition metal and aluminosilicate technology, which is applied in the field of preparation of iron-based late-transition metal vinyl polymer catalysts, can solve problems such as instability, stickiness, and low apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of the modified carrier: Add 600ml of distilled water to three 1000ml bottles, weigh 30g of artificial sodium-based montmorillonite and slowly add to the three bottles while stirring, and heat. Weigh 10g of cetyltrimethylammonium bromide, dissolve it with a small amount of absolute ethanol, and heat it appropriately. Add hexadecyltrimethylammonium bromide ethanol solution when the artificial sodium montmorillonite distilled water suspension is heated to about 70°C. Mix briskly for about 2 minutes, returning to original mixing speed. At the same time, the temperature was raised to 80° C. and maintained at a constant temperature of 80° C. for about two hours. Then pour out the product, wash it with distilled water until it becomes neutral, filter it with suction, dry it at 80°C, pulverize it with a universal pulverizer, sieve it, and set it aside.

[0030] Loading the iron-based late transition metal complex on the MAO-treated modified montmorillonite: befor...

Embodiment 2

[0033] Preparation of the modified carrier: Add 600ml of distilled water to three 1000ml bottles, weigh 30g of artificial calcium-based montmorillonite, slowly add it to the three bottles while stirring, and heat. Weigh 10g of octadecyltrimethylammonium chloride, dissolve with a small amount of absolute ethanol, and heat appropriately. When the temperature of the artificial calcium-based montmorillonite distilled water suspension is raised to about 80° C., an ethanol solution of octadecyltrimethylammonium chloride is added. Mix briskly for about 2 minutes, returning to original mixing speed. At the same time, the temperature was raised to 90° C. and maintained at a constant temperature of 90° C. for about two hours. Then pour out the product, wash it with distilled water until it becomes neutral, filter it with suction, dry it at 90°C, pulverize it with a universal pulverizer, sieve it, and set it aside.

[0034]Loading the iron-based late transition metal complex on the MAO...

Embodiment 3

[0038] Carrier preparation: same as Example 1.

[0039] Directly load the modified montmorillonite with the iron-based late-transition metal complex: at 25°C, empty the 500ml three-necked flask with nitrogen before the reaction, so that the whole reaction is carried out under the protection of nitrogen. 200ml of heptane was added into the three-necked flask (calcium hydride was refluxed for 24 hours), and 50g of the above-prepared montmorillonite was added under stirring to suspend it uniformly in the heptane solvent. Add dissolved 50mg {[2,6-ArN=C(Me) 2 C 5 h 3 N]FeCl 2}(Ar=2,6-iPr 2 C 6 h 3 ) is the heptane solution of the complex, slowly added dropwise for 2 hours under stirring at normal temperature, and then added 2ml of heptane in the feeding tube, and continued to react for 8 hours at 25° C. under normal pressure. After the reaction, the reaction product was repeatedly washed with heptane under the protection of nitrogen, and stored in a collection bottle in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com