Phosphorus containing siloxane and process for preparing same

A technology of polysiloxane and dihydroxysiloxane, which is applied in the field of side chain phosphorus-containing polysiloxane and its preparation, and can solve problems such as uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

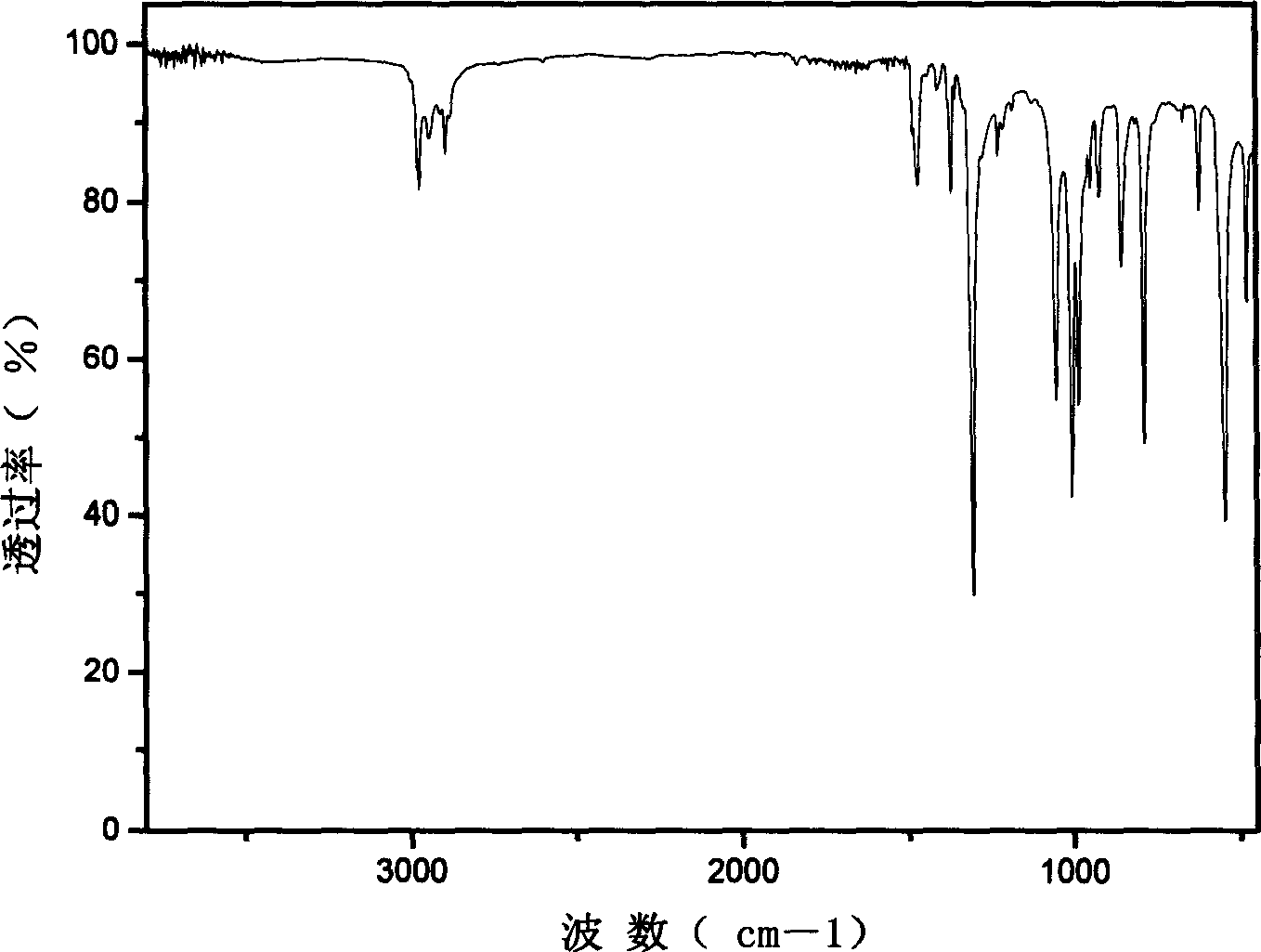

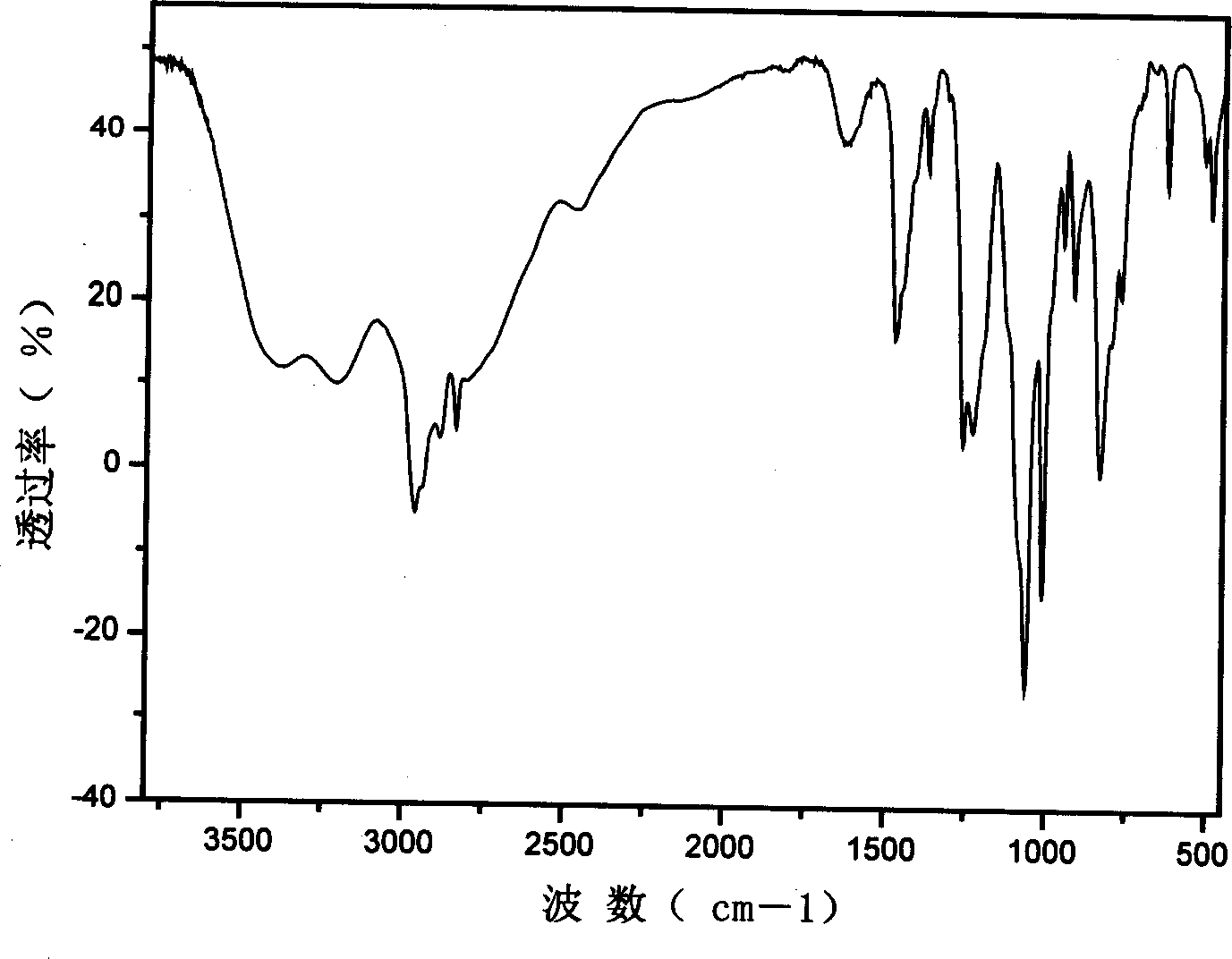

[0036] (a) Weigh 1 mol of neopentyl glycol, add it into 300 ml of chloroform, stir and raise the temperature to dissolve. Then control the temperature at 0°C, and add 1 mol of phosphorus oxychloride dropwise. After the phosphorus oxychloride was added dropwise, the temperature was raised to 20°C and kept at this temperature for 4 hours. Chloroform was removed, and the product obtained was treated with benzene, CCl 4 , washed with absolute ethanol three times respectively, and dried in an oven at 80° C. for about 10 hours to obtain a phosphorus oxychloride compound. attached figure 1 It is the infrared spectrogram of phosphorus oxychloride compound: FTIR (KBr, cm -1 ): 2896~2975 (-CH 2 -, -CH 3 ); 1304 (P=O); 1000-1100 (P-O-C); 540 (P-Cl).

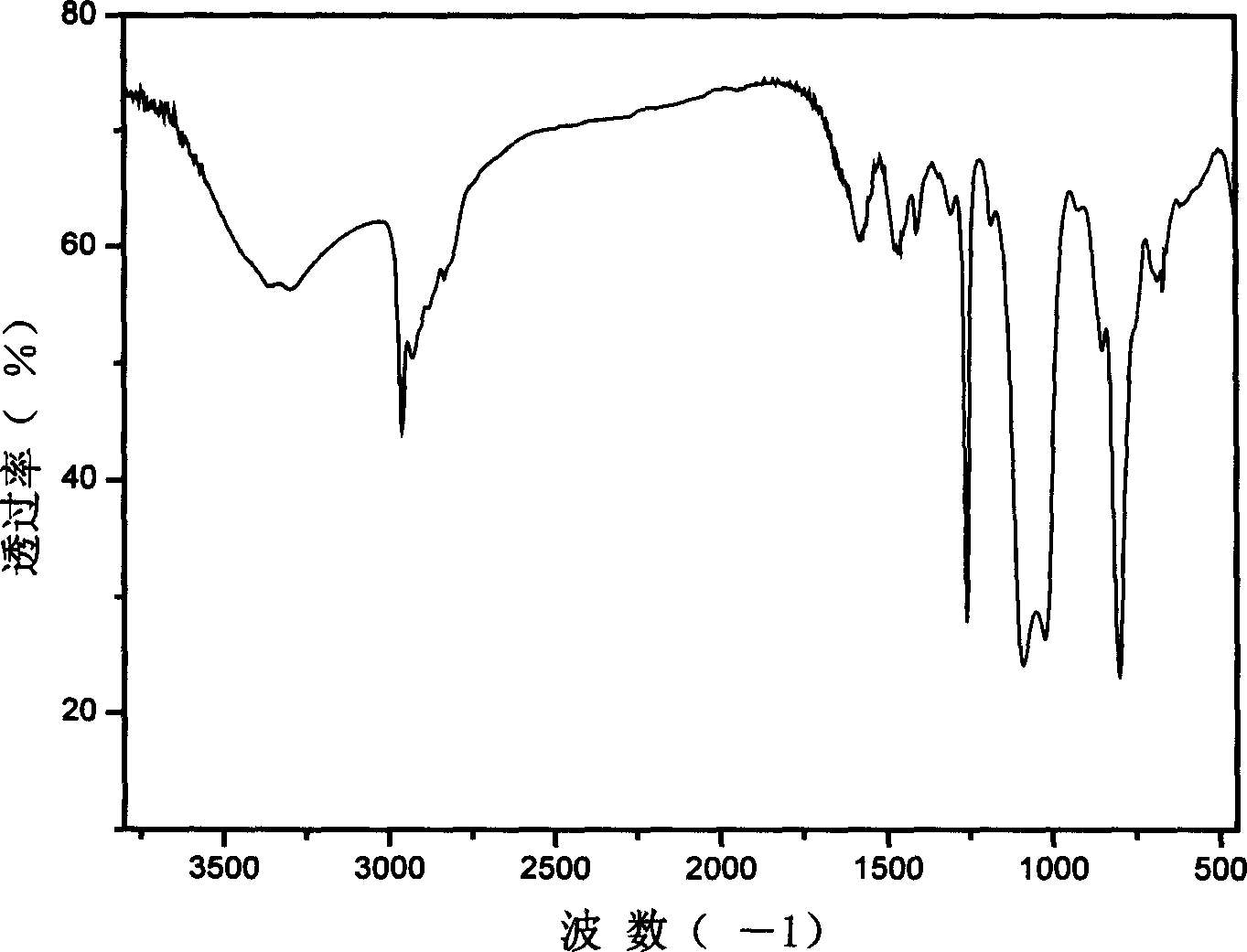

[0037] (b) Weigh 1 mol of amino-containing siloxane (r=3, q=2), add 2 mol of water, 0.01 mol of potassium hydroxide, heat up to 80-100°C, keep the temperature at constant temperature for 12 hours under the protection of nitrogen, and ...

Embodiment 2

[0041] (a) Weigh 1 mol of neopentyl glycol, add it into 300 ml of chloroform, stir and raise the temperature to dissolve. Then control the temperature at 0°C, and add 1 mol of phosphorus oxychloride dropwise. After the phosphorus oxychloride was added dropwise, the temperature was raised to 20°C and kept at this temperature for 4 hours. Chloroform was removed, and the obtained product was washed three times with absolute ethanol, and placed in an oven at 80° C. for about 10 hours to obtain a phosphorus oxychloride compound.

[0042] (b) Weigh 1 mol of amino-containing siloxane (r=3, q=2), add 2 mol of water, 0.01 mol of potassium hydroxide, heat up to 80-100°C, keep the temperature at constant temperature for 12 hours under the protection of nitrogen, and remove the water , to obtain the hydrolysis product of aminosilane.

[0043] (c) Weigh the hydrolyzate of 0.5mol aminosilane and 0.5mol of α, ω-dihydroxydimethylsiloxane (R1, R2 are both CH 3 ) and 0.5mol of another α, ω-d...

Embodiment 3

[0046] According to Example 1, 30 g of the phosphorus-containing polysiloxane flame retardant and 70 g of polypropylene were put into an internal mixer and mixed uniformly at a mixing temperature of 170° C. for 8 minutes to obtain a flame-retardant polypropylene. Its oxygen index is 27.0, and a very high char formation rate is obtained at 800°C (in nitrogen: 27%; in air: 12%; in oxygen: 13%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com