Prepn process of superfine xonotlite fiber

A technology of tobermorite and fiber, which is applied in the field of preparation of ultrafine tobermorite fibers and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

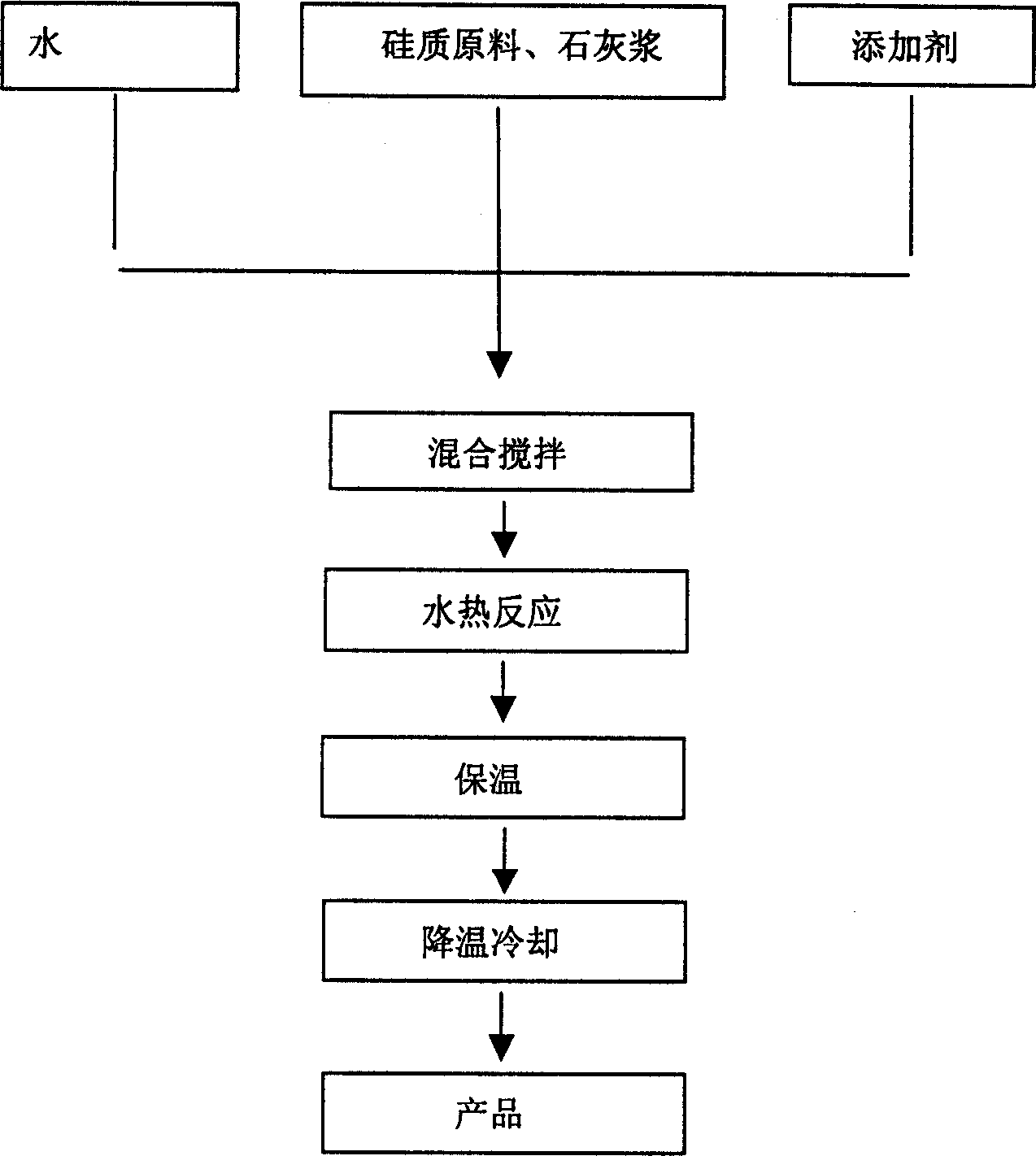

Method used

Image

Examples

Embodiment Construction

[0017] Calcium raw materials and siliceous raw materials (the main particle size is 5--20μm, d 50 The main chemical composition is shown in Table 1.

[0018] Table 1 Chemical Composition of Raw Materials

[0019] raw material

SiO 2

Al 2 o 3

Fe 2 o 3

CaO

MgO

K 2 o

Na 2 o

TiO 2

5.14

0.60

0.23

87.35

5.39

0.07

0.07

0.01

0.52

99.01

0.07

0.05

0.02

0.01

0.02

0.04

0.01

0.64

[0020] 1. Digest the lime in water at 40°C and soak it for 10 days to convert it into Ca(OH) 2 , and then pass through a 200-mesh sieve to remove impurities. Determination of effective CaO content. The method is to stir the clarified lime slurry evenly, first use a specific gravity meter to measure its specific gravity, then take 50ML of mortar and put it in a conical flask, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com