Cubic liquid crystalline compositions and methods for their preparation

A cubic and compound technology, applied in the field of cubic liquid crystal composition and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] Example 1 - Starch - Encapsulated Glyceryl Monooleate Powder

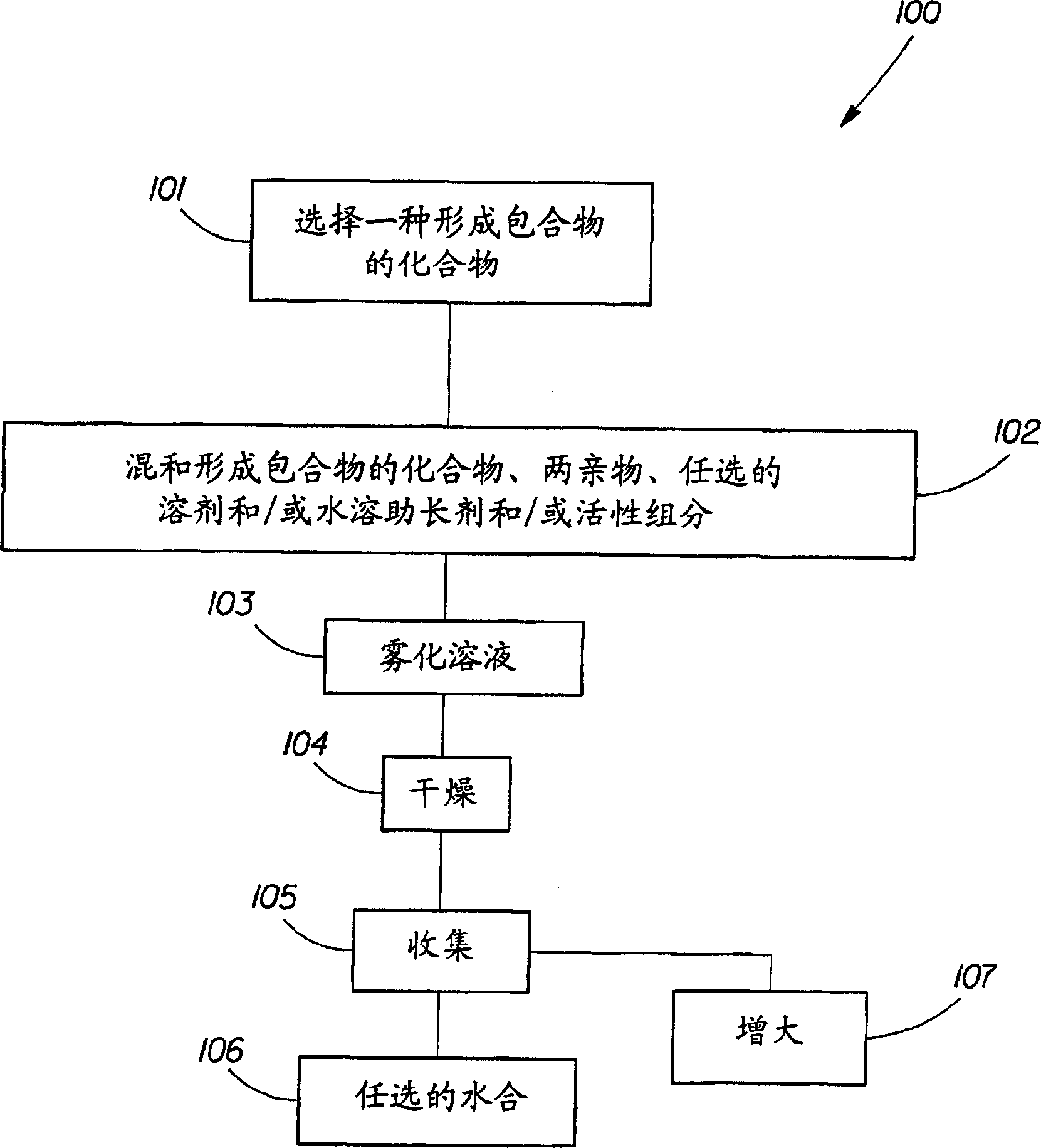

[0118] Use a Yamato Pulvis Basic spray drying unit (see figure 1 ) to produce powder. A dual flow nozzle with a liquid aperture of 0.040 inch (0.1 cm) and an air aperture of 0.1 inch (0.25 cm) was inserted into the top of the Yamato Pulvis spray dryer body. The body of the spray dryer consists of a drying chamber and a cyclone collector at the air outlet. A spray dryer is configured to flow heated drying air down through a nozzle. The heated dry air was set at 200°C. Sonicate the liquid crystal material with a sonicator. The feed was stirred at 25°C with a stir bar.

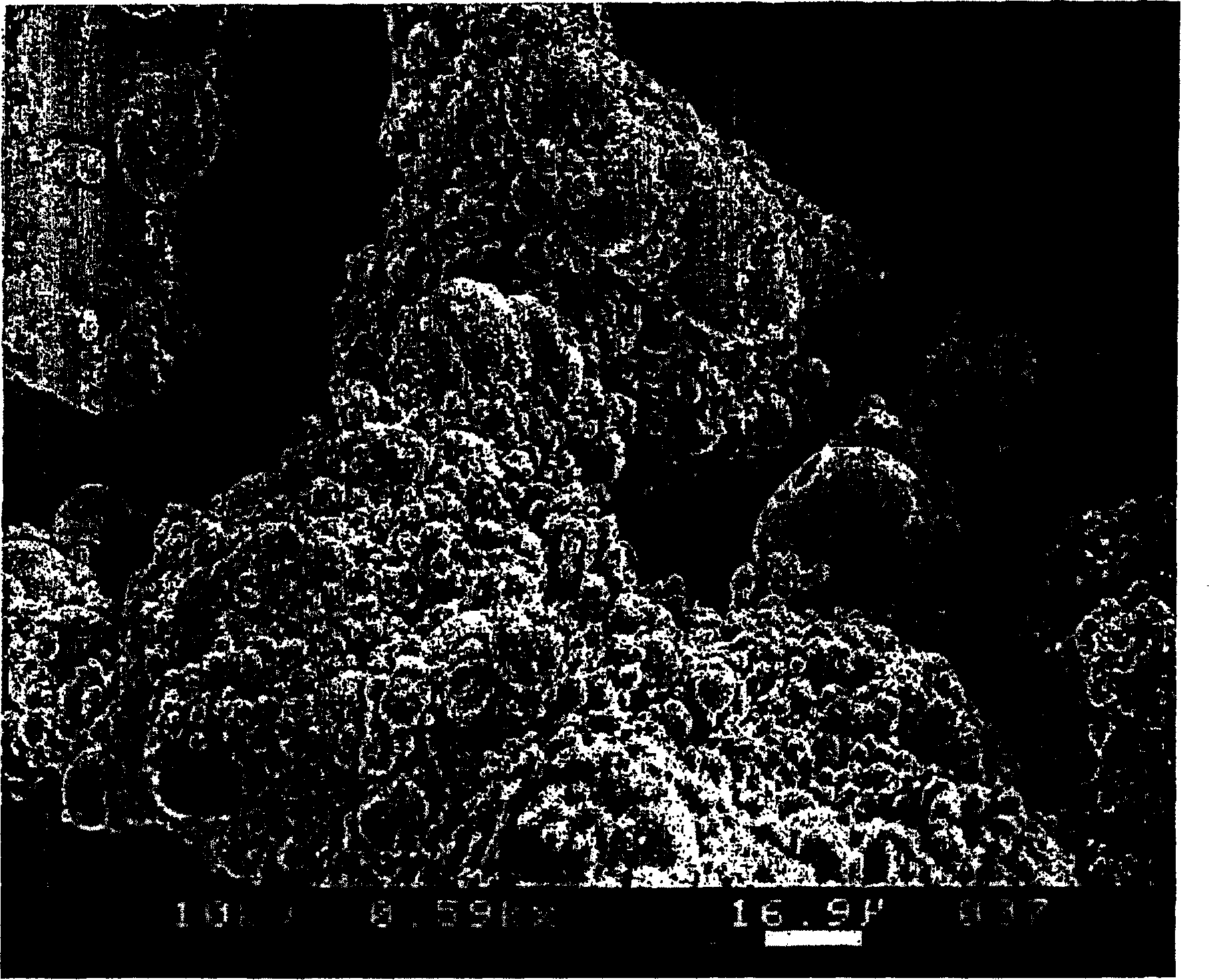

[0119] A spray-dried mixture of glyceryl monooleate (10% w / w), water (60%) and HI-CAP starch (30%) produced a first dry powder precursor. The resulting powder contained 25% glycerol monooleate and 75% starch, assuming all added water was removed. Subsequent measurements showed 4% to 10% moisture in the dried powder. After hydration of g...

Embodiment 2

[0122] Embodiment 2-starch-glycerol monooleate-hydrotrope powder

[0123]It has been found that adding a sufficient amount of hydrotrope to an aqueous glyceryl monooleate system produces low viscosity precursors which are easy to handle. The present invention improves upon these techniques to provide a method for more facile production of spray-dried cube precursors. The use of hydrotropes mimics the desired properties of active loaded systems, since many useful actives are also hydrotropes. Instead of ethanol, sodium p-toluenesulfonate (STS) was chosen because of its high melting point. In the case of starch-monooleate-water, use a mixture of glycerol monooleate (8% w / w), STS (8%), starch (24%) and water (60%) to form an easy pump A flowable liquid is supplied and maintained homogeneous by stirring to prepare a powder. The mixture was pumped through the liquid side of the two-fluid nebulizer at 6 mL / min, adjusting the pumping rate slightly to maintain the temperature of th...

Embodiment 3

[0125] Example 3 - Encapsulation of Active Ingredient (Fatty Acid Solution) in Powder

[0126] Powders are produced by spray drying liquid solutions. A liquid solution was prepared at 70°C from a premix of 67% water and 33% starch. A second solution of a mixture of 90% glycerol monooleate and 10% fatty acid (20% omega-3, 80% triglyceride oil) was prepared at 60°C. The oil solution was added to the starch-water solution to form A mixture of 9% Glyceryl Monooleate, 30% Starch, 60% Water and 1% Fatty Acid. The system was mixed using a high shear mixing system and maintained above 90°C. The mixture was pumped through the liquid side of the two-fluid nebulizer at a rate of 8 mL / min, adjusting the flow rate slightly to maintain the outlet air temperature of the system at 90°C-100°C. The liquid feed was atomized with air at a pressure of 42.6 psi (293.5 kPa). After drying, the powder had a composition of a mixture of 22.5% glyceryl monooleate, 75% starch and 2.5% fatty acid.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com