Hydrocarbon reforming catalyst containing molecular sieve

A reforming catalyst and molecular sieve technology, applied in the reforming of naphtha, petroleum industry, etc., can solve problems such as environmental pollution, easy loss of chlorine, complex reforming operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of catalyst provided by the invention comprises the steps:

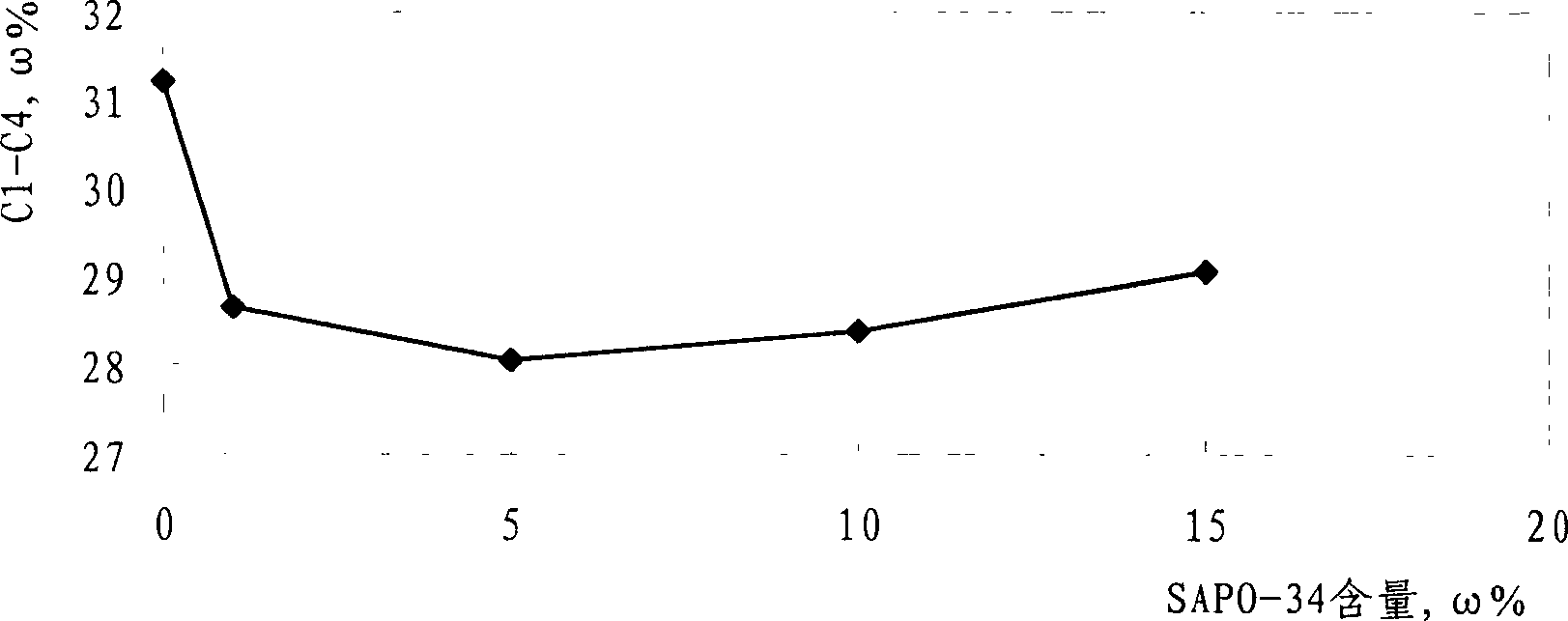

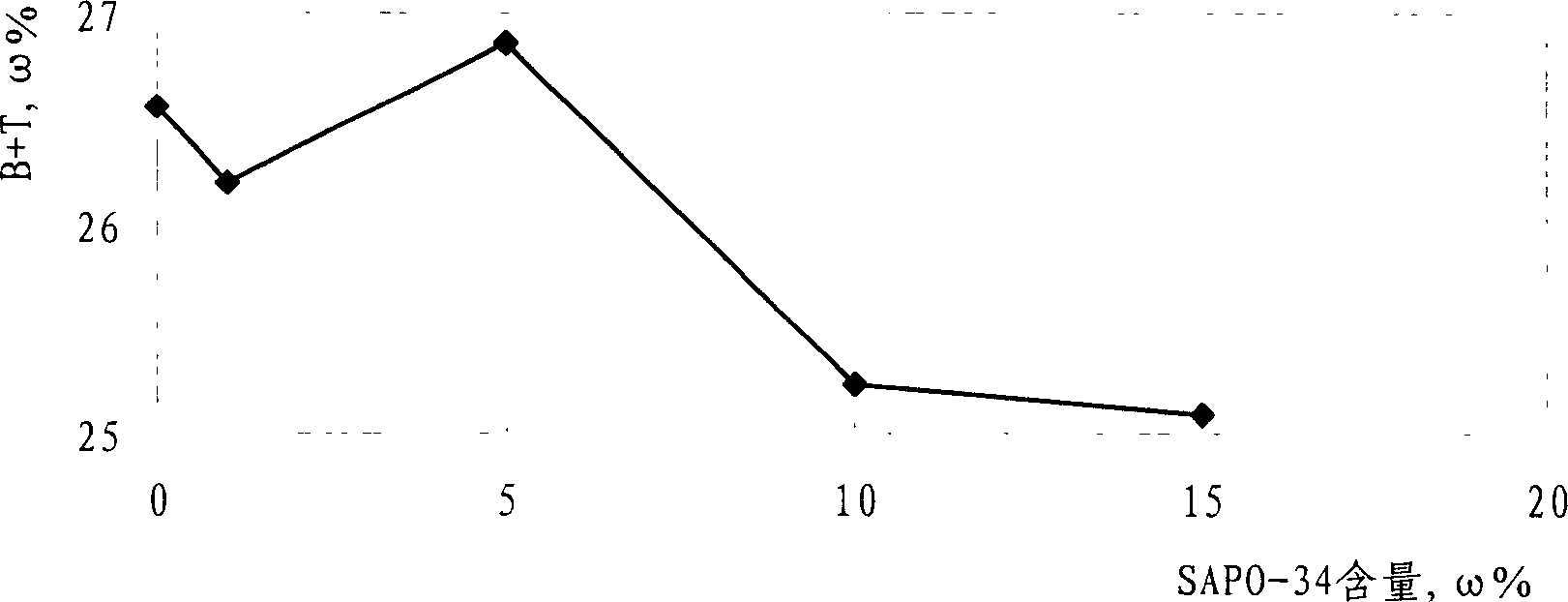

[0026] (1) Mix aluminum hydroxide powder and SAPO molecular sieve uniformly at a dry basis weight ratio of 85.0~99.0:1.0~15.0, extrude, dry and roast to obtain the carrier,

[0027] (2) Prepare the impregnating liquid with platinum-containing compound and rhenium-containing compound, impregnate the carrier prepared in step (1) according to the liquid / solid ratio of 1.0-2.0:1, dry and then roast.

[0028] The small-pore SAPO molecular screen described in the above method is selected from SAPO-34, SAPO-35, SAPO-17 or SAPO-44, preferably SAPO-34.

[0029] In the process of preparing the carrier in the above (1) step, first mix the aluminum hydroxide powder with the SAPO molecular sieve according to the dry weight, that is, the weight of the aluminum oxide contained therein, and then add an appropriate amount of water, extrusion aid, and peptizer to knead evenly Post-extrusion strip molding...

example 1

[0039] Preparation of the catalyst of the present invention.

[0040] (1) Prepare a carrier containing SAPO-34 molecular sieve.

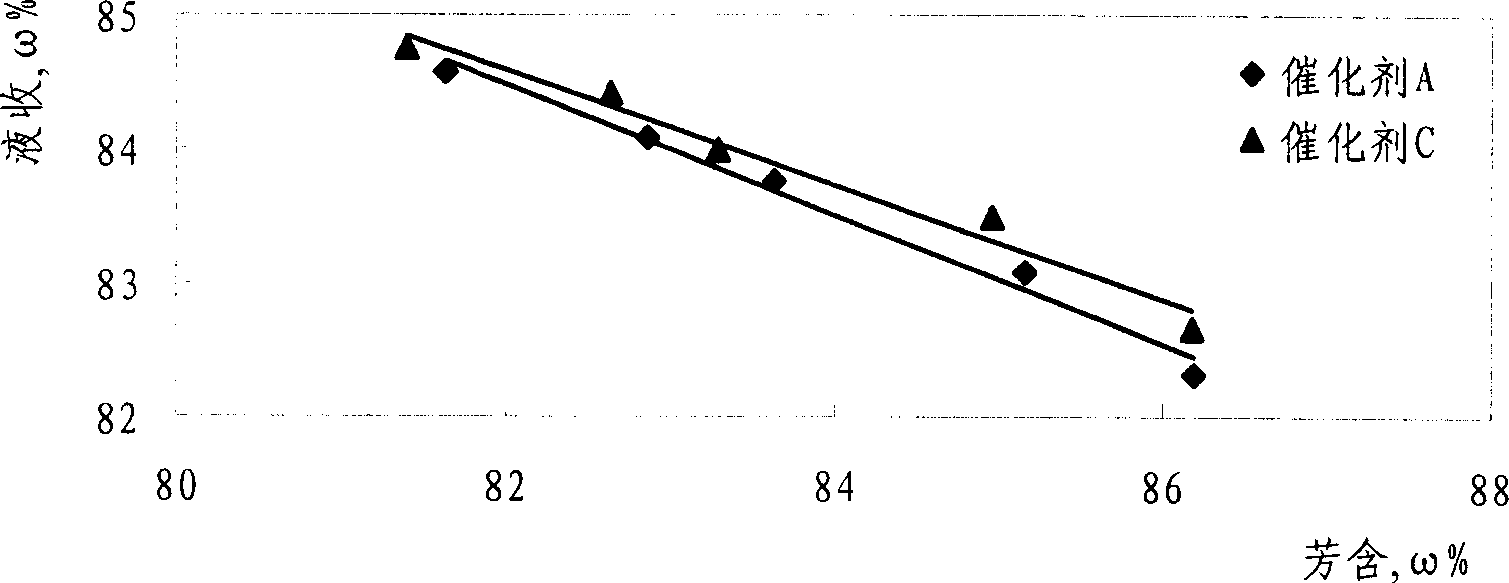

[0041]Get 100 grams of aluminum hydroxide powder (produced by South Africa Sasol Company, brand SB), its dry basis weight is 75 grams, mix with 0.75 grams of SAPO-34 molecular sieve, 2 grams of turnip powder, then add 4 grams of citric acid, 3 milliliters 1:1 nitric acid solution, 7 milliliters of 36% acetic acid solution and 60 milliliters of deionized water, fully kneaded and evenly extruded into strips, and then cut into particles with a length of 3-6 mm. Aged at 30°C for 12 hours, dried at 60°C for 6 hours, dried at 120°C for 12 hours, and calcined at 650°C for 4 hours to obtain a bar-shaped carrier b containing SAPO-34 molecular sieve. The content of SAPO-34 in carrier b is shown in Table 1.

[0042] (2) Preparation of catalyst

[0043] Chloroplatinic acid, perrhenic acid and hydrochloric acid were made into an impregnating solution, so that ...

example 2

[0045] Catalyst C was prepared according to the method of Example 1, except that the SAPO-34 added when preparing the carrier was 3.94 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com