Metaporous silicon dioxide material and its preparing method

A mesoporous silica and mesoporous technology, applied in the direction of silica, silicon oxide, chemical instruments and methods, etc., can solve the problems of large amount of surfactant, material structure damage, difficult removal, etc. The effect of small dosage and concentrated hole distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

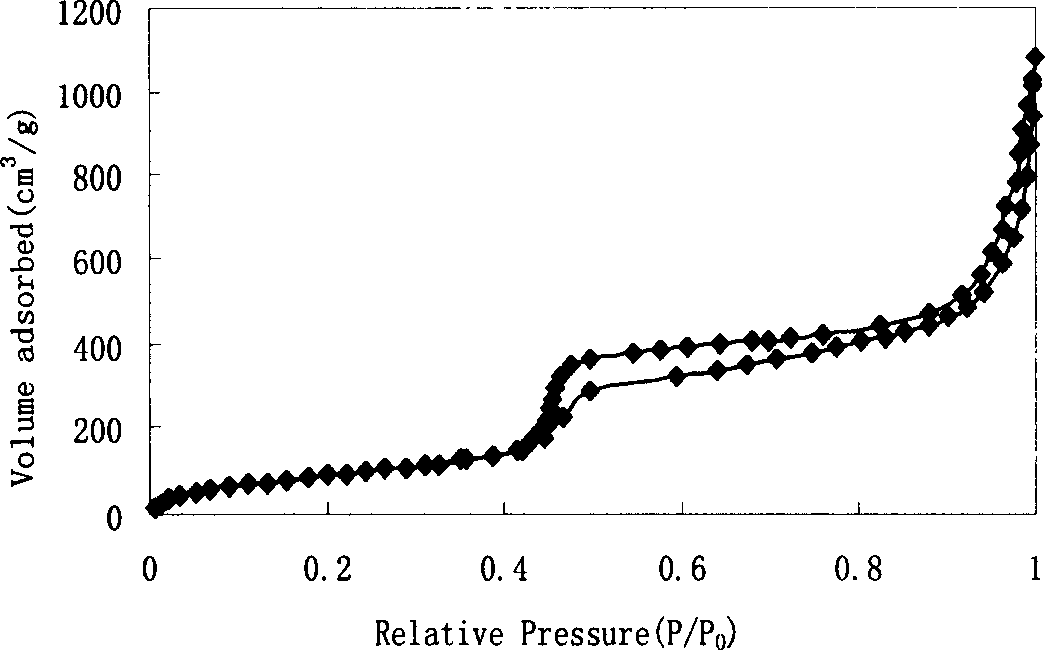

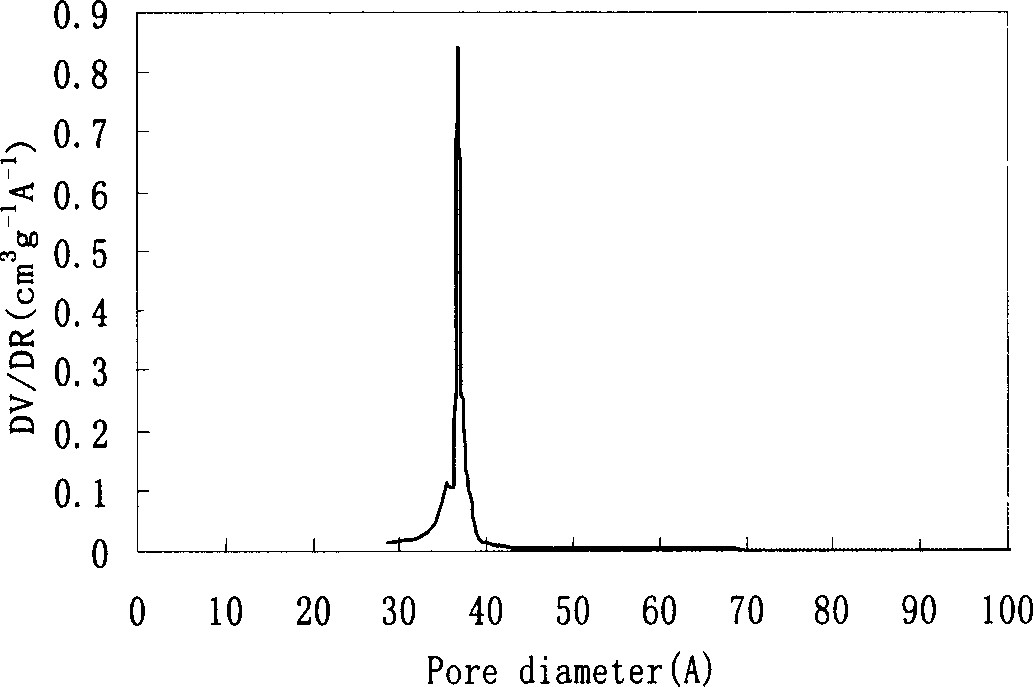

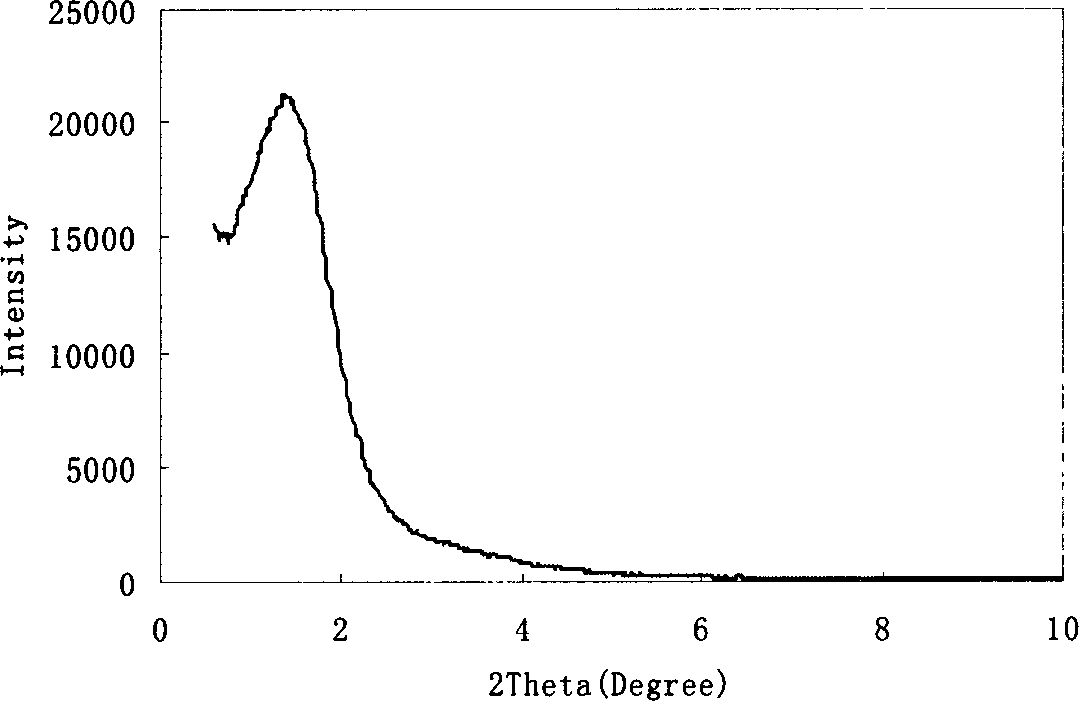

[0016] Add 0.3156g of DDAC to 41g of distilled water and mix, place in an ultrasonic cleaner at 50°C for 1 hour to obtain a transparent and clear surfactant solution, adjust the pH of the solution to about 12.0 with NaOH, stir at 50°C and slowly add 2.0833 g orthosilicate, continue to stir for 24 hours, a large amount of white precipitates will form along with the stirring, seal and age at 70°C for 4 days, filter, wash with distilled water, and dry, then reflux the precipitates in methanol / hydrochloric acid solution for 48 hours, wash with methanol After drying, the mesoporous silica material is obtained. The characterization results are shown in the accompanying drawings: figure 1 , figure 2 , image 3 (Other embodiments are similar to this figure). Mesoporous silica material BET specific surface area: 372.90m 2 / g; Pore volume: 0.80m 3 / g; pore size 3.7nm.

Embodiment 2

[0018] Add 0.3156g of DDAC to 41g of distilled water and mix, place in an ultrasonic cleaner at 50°C for 30 minutes to obtain a uniform and transparent surfactant solution, adjust the pH of the solution to 12.0 with NaOH, stir at 20°C and slowly add 2.0833g of positive Ethyl silicate, continue to stir for 24 hours, a large amount of white precipitates will form along with the stirring, seal and age at 70°C for 4 days, filter, wash with distilled water, and dry, then reflux the precipitate in methanol / hydrochloric acid solution for 48 hours, wash with methanol, and dry After that, the mesoporous silica material is obtained. Mesoporous silica material BET specific surface area: 836.79m 2 / g; Pore volume: 1.10m 3 / g; pore size 3.6nm.

Embodiment 3

[0020] Add 0.3156g of DDAC to 41g of distilled water and mix, place in an ultrasonic cleaner at 50°C for 1 hour to obtain a uniform and transparent surfactant solution, adjust the pH of the solution to 11.9 with NaOH, stir at 70°C and slowly add 2.50g of positive Ethyl silicate, a large amount of white precipitate will form after the dropwise addition, continue to stir for 24 hours, seal and age at 70°C for 4 days, filter, wash with distilled water, and dry, then reflux the precipitate in methanol / hydrochloric acid solution for 48 hours, wash with methanol, After drying, the mesoporous silica material is obtained. Mesoporous silica material BET specific surface area: 674.5m 2 / g; Pore volume: 0.86m 3 / g; pore size 3.5nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com