Optical fiber gas sensor

A technology of gas sensor and optical fiber, which is applied in the field of microstructure optical fiber gas sensor, can solve the problems of long response time and attenuation, and achieve the effect of shortening gas diffusion time and response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

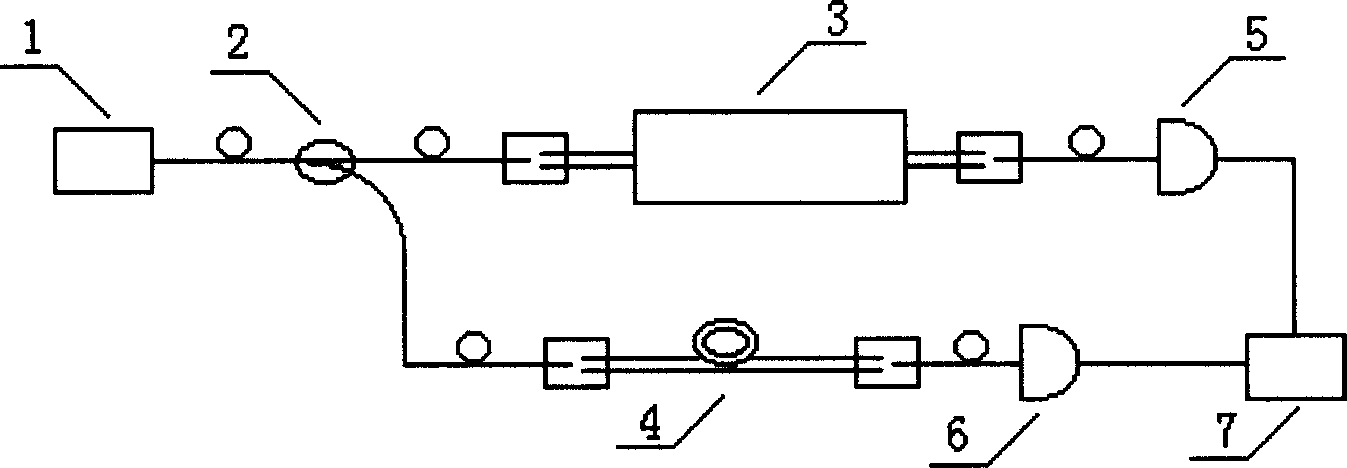

[0029] An embodiment of the present invention: as image 3 A fiber optic gas sensor shown includes a light source 1 connected by a common solid-core fiber, a coupler 2, a gas absorption cell 3, a comparison fiber 4, photodetectors 5, 6, and a signal acquisition and processing system 7. The optical fiber 8 in the gas absorption cell 3 and the comparison optical fiber 4 are Bragg hollow-core fibers, of course, photonic crystal hollow-core fibers can also be used. The connection relationship is as follows: light source 1 is connected to the input of coupler 2, one output of coupler 2 is connected to gas absorption cell 3, gas absorption cell 3 is connected to photodetector 5, and the other output of coupler 2 is connected to contrast fiber 4, and the contrast The optical fiber 4 is connected to the photodetector 6 again, and the outputs of the photodetectors 5 and 6 are connected to the signal acquisition and processing system 7 .

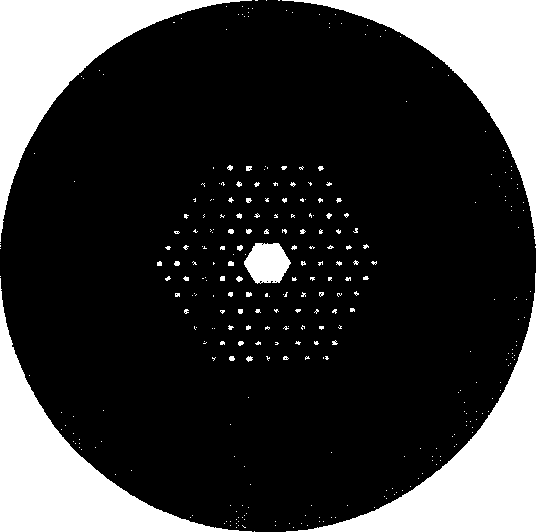

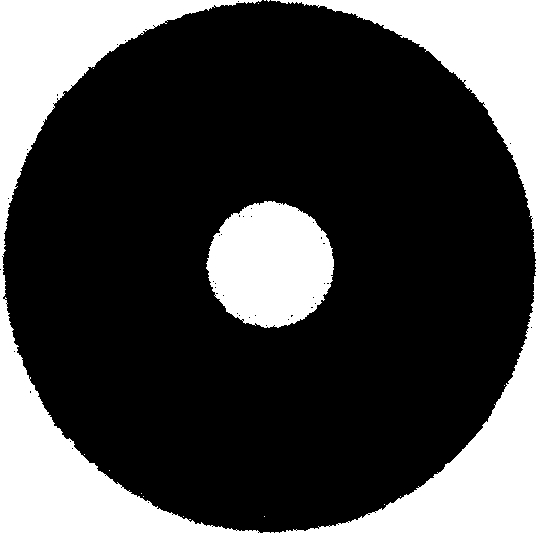

[0030] Wherein the structure of the gas absorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com