Ultra-low repeated frequency high-voltage rectangular pulse power supply

A repetition frequency, rectangular pulse technology, applied in the field of ultra-low repetition frequency high-voltage rectangular pulse power supply, can solve the problems of high cost, lack of general promotion, difficult to guarantee the pulse waveform, etc., to achieve the effect of increasing the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

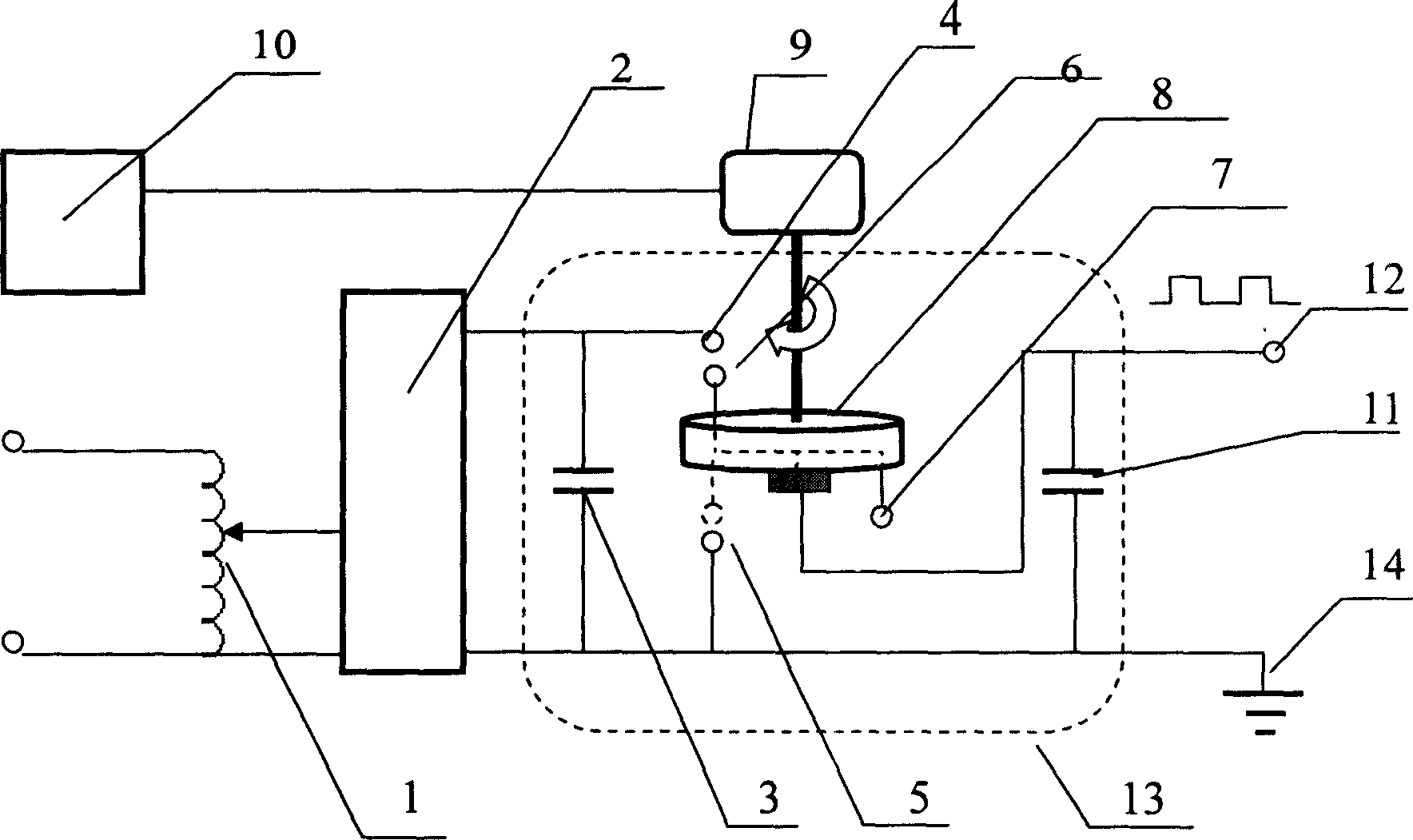

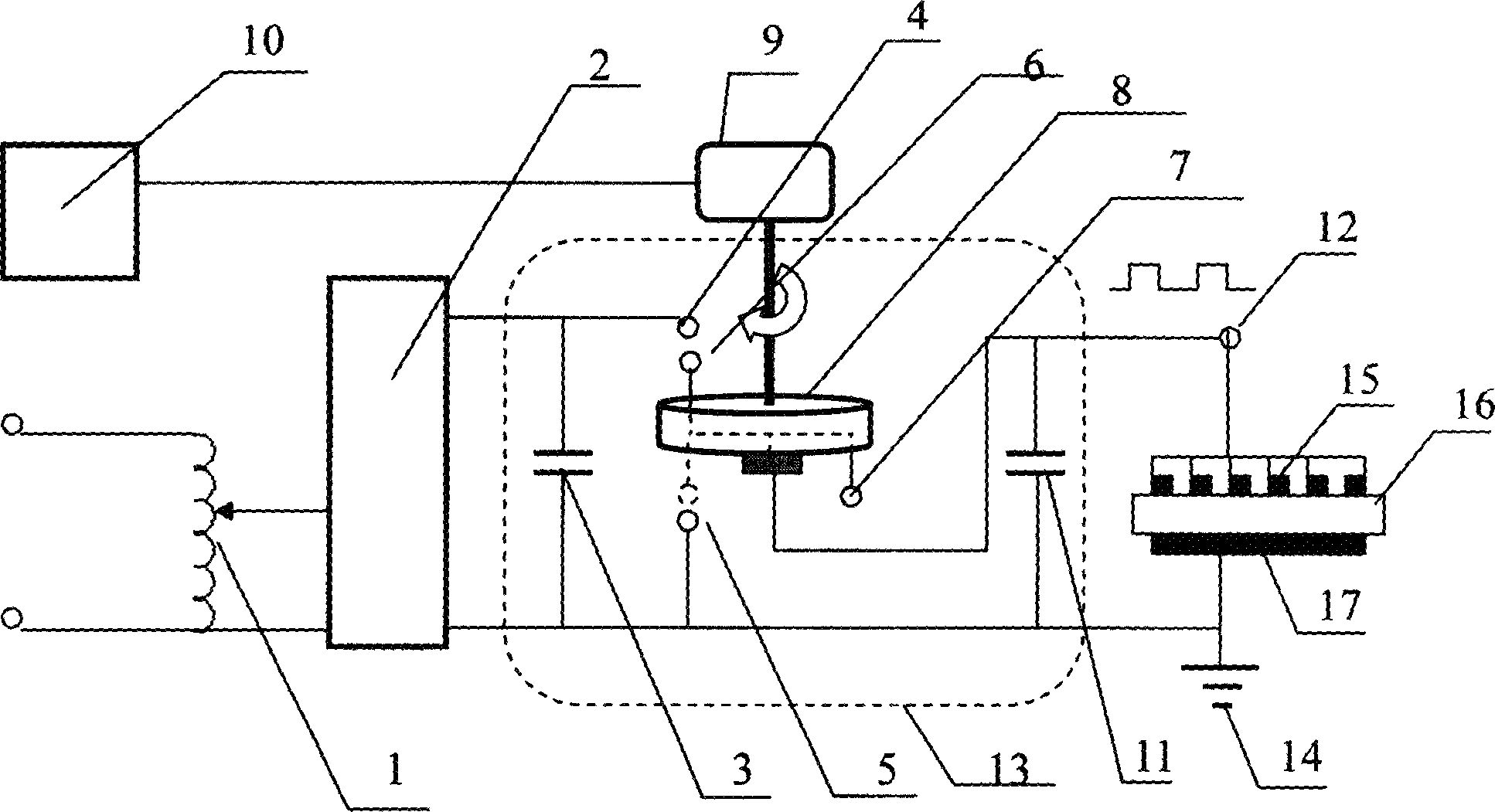

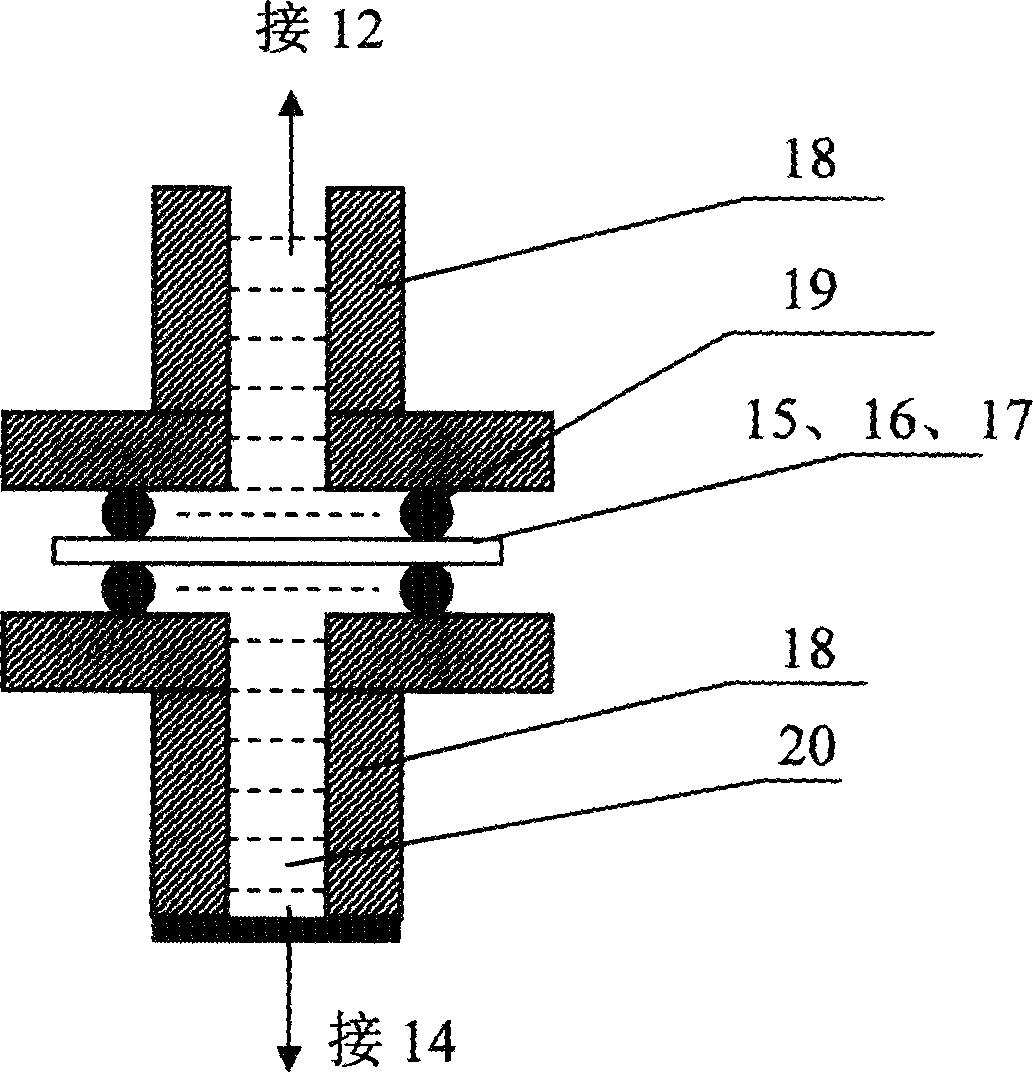

[0020] exist figure 1 Among them, the voltage regulator 1 supplies power to the high voltage direct current power supply 2, so that the output voltage of the high voltage direct current power supply 2 can be adjusted. The output end of the high-voltage DC power supply 2 is connected to the energy storage capacitor 3 and the fixed electrode 4 , and the output electric energy is stored in the energy storage capacitor 3 . The fixed electrode 4 and the rotating electrode 6 form a spark gap, and the fixed electrode 5 is grounded and the rotating electrode 7 forms a spark gap. The rotating electrode 6 and the rotating electrode 7 are fixed on the flying disc type mechanical spark switch 8, the flying disc type mechanical spark switch 8 is made of an insulating plexiglass plate, and is driven to rotate by the stepping electrode 9. The rotational speed of the stepper motor 9 is controlled by a controller 10 . The rotating electrode 6 and the rotating electrode 7 are connected by wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com