Laser cutting device, laser cutting method and laser cutting system

A technology of laser cutting and conveying device, used in laser welding equipment, welding/welding/cutting items, transportation and packaging, etc., can solve the problems of unreliable support and delivery of parts, damage and establishment of parts on the reverse side, and improve production efficiency , the effect of preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

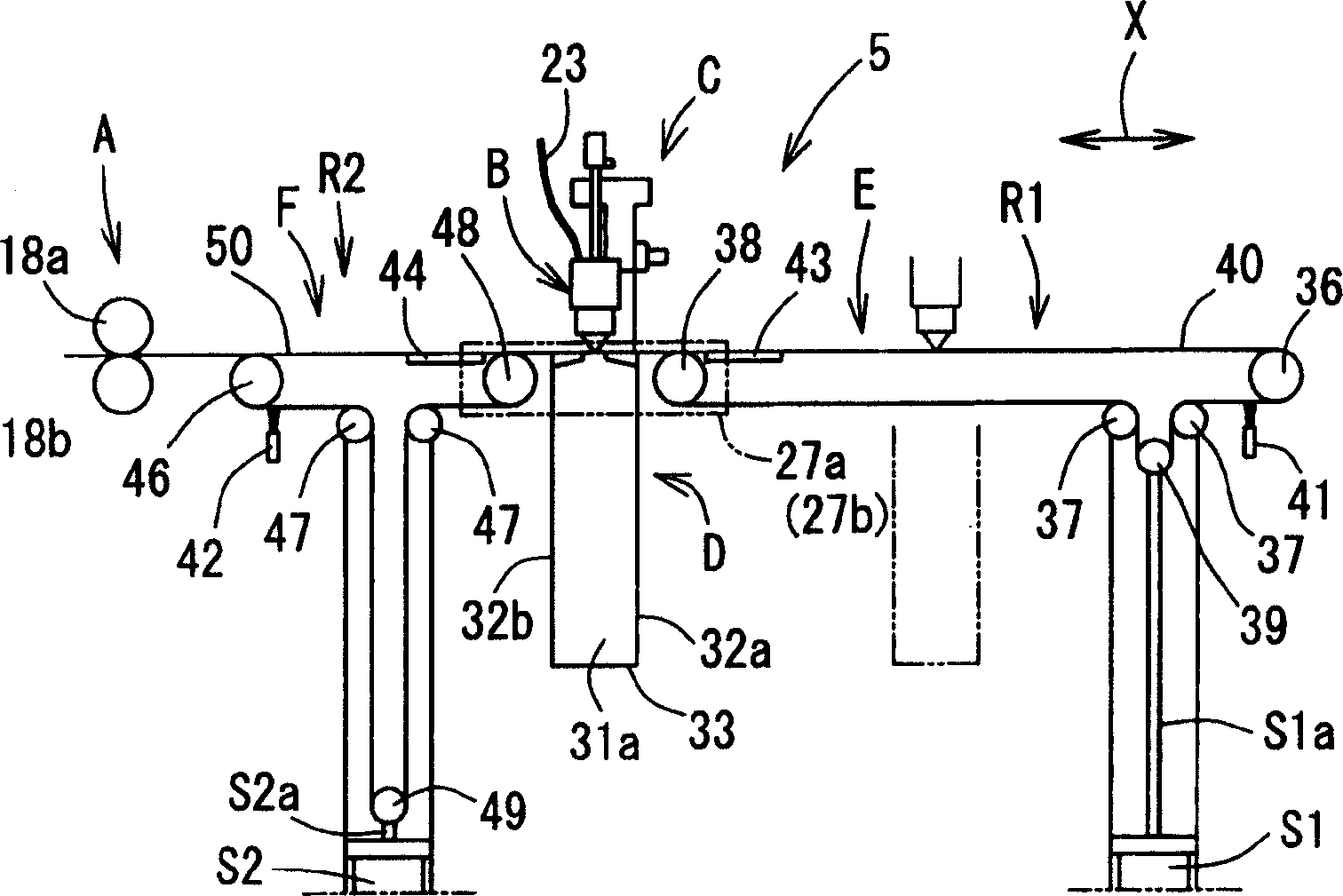

[0119] The present invention will be described in detail below through embodiments with reference to the accompanying drawings.

[0120] In the following embodiments, "left" and "right" represent the width direction Y of the sheet-like material (hereinafter simply referred to as the sheet) 11, and "front" and "rear" represent the feeding direction X of the sheet.

[0121] 1. Structure of laser cutting system

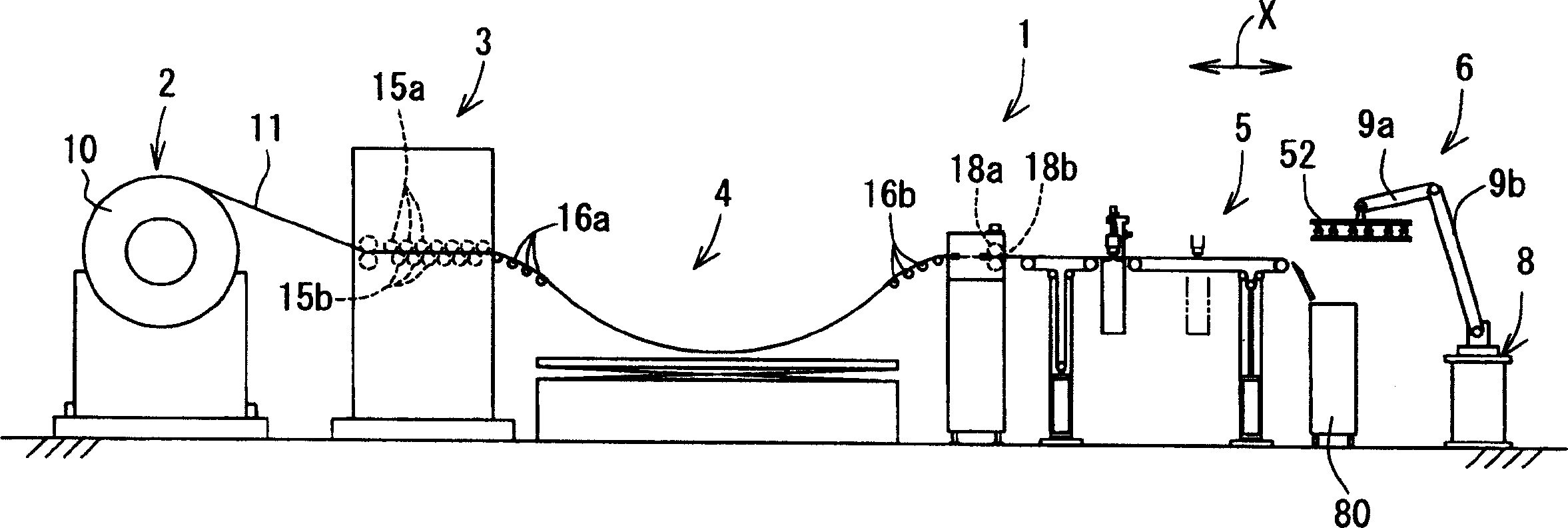

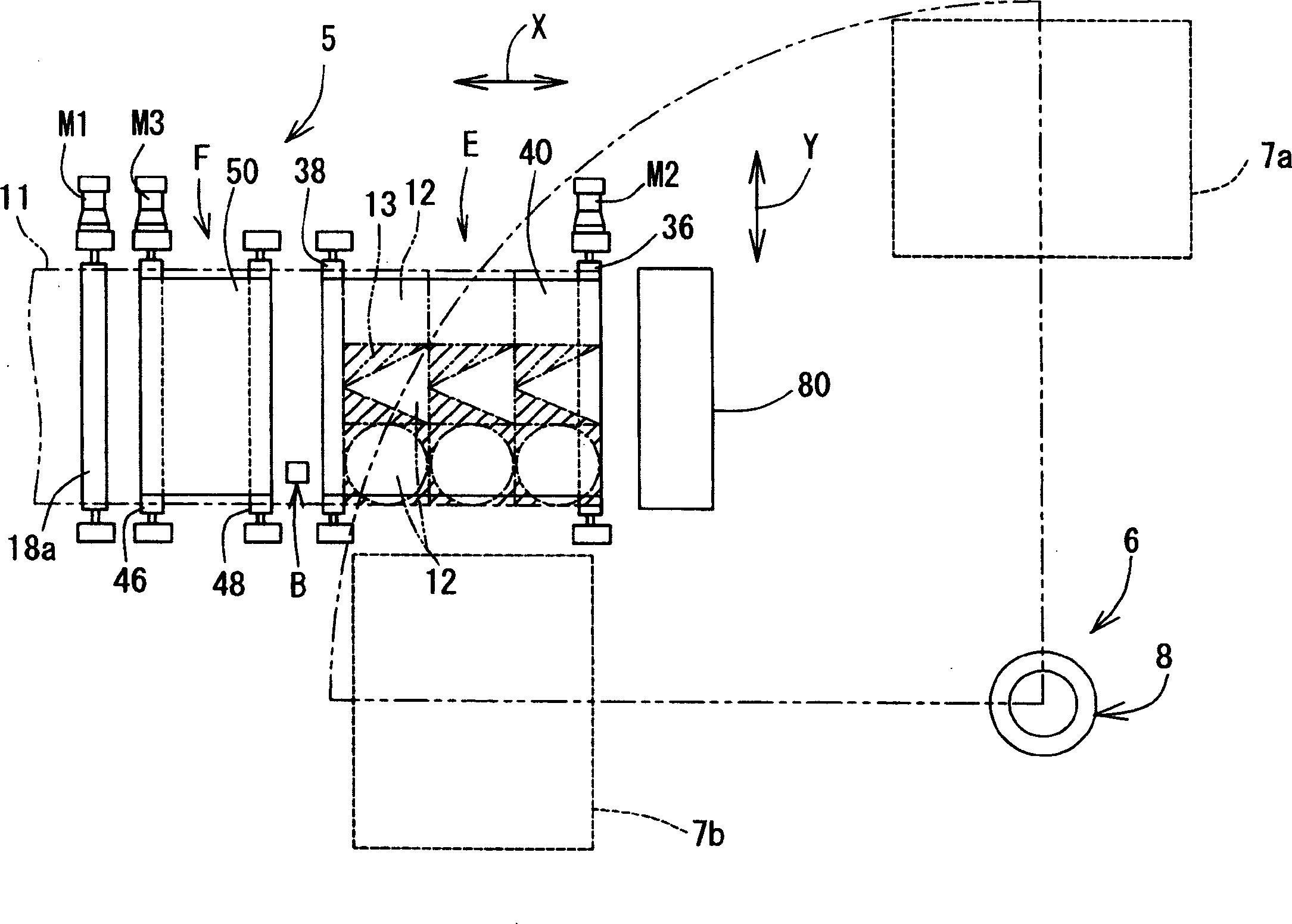

[0122] Such as figure 1 As shown, the structure of the laser cutting system 1 of this embodiment basically includes: a coil support device 2 disposed on the most upstream side, a leveling device 3 disposed on the downstream side of the coil support device 2, a leveling device disposed on the leveling device 3. The buffer curve forming part 4 on the downstream side, the laser cutting device 5 arranged on the downstream side of the buffer curve forming part 4, and the separation and recovery device 6 arranged on the downstream side of the laser cutting device 5.

[0123]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com