In-situ detection method for stray light in step scan projection mask aligner

A step-scanning and in-situ detection technology, which is applied in microlithography exposure equipment, machine/structural component testing, optical instrument testing, etc., can solve problems such as the inability to distinguish the source of stray light, eliminate stray light, and improve measurement efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

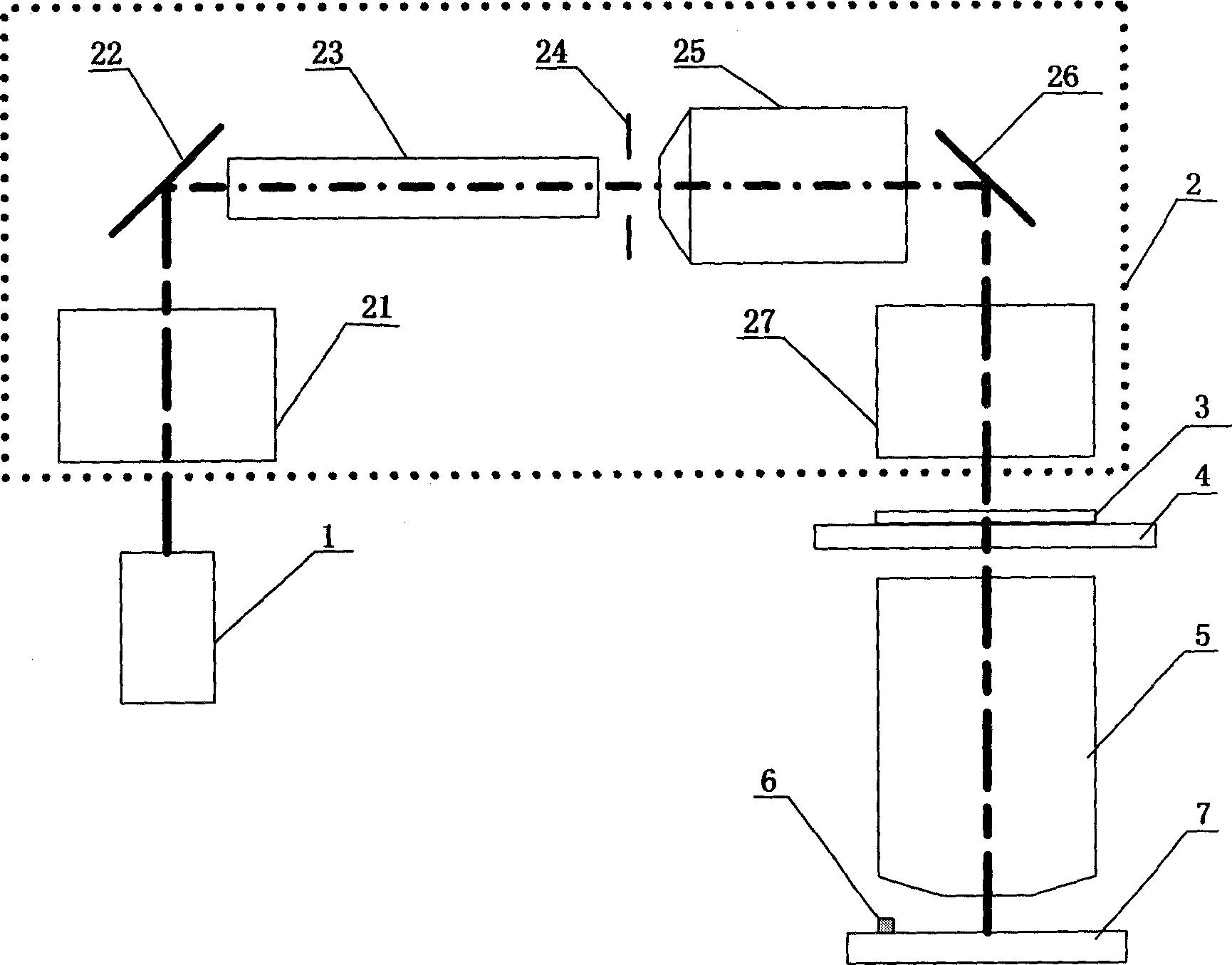

[0032] The invention provides an in-situ detection method for stray light in a step-scan projection lithography machine, which can not only measure the size of the stray light, but also analyze the source of the stray light, providing a basis for taking targeted measures to eliminate the stray light in accordance with. The system structure used by the method is as follows figure 2 As shown, it includes: a light source 1 for generating a projected light beam; an illumination system 2 capable of adjusting the light intensity distribution and partial coherence factor of the light beam emitted by the light source 1; a mask 3; a mask capable of carrying the mask 3 and precisely positioned A mold stage 4; a projection objective lens 5 for imaging the mask 3 and whose numerical aperture is adjustable; a workpiece stage 7 capable of carrying silicon wafers and capable of precise positioning, and an energy sensor 6 arranged on the workpiece stage 7.

[0033] The lighting system 2 mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com