Flame resisting wave absorption base material and process for making same

A kind of flame retardant and base material technology, which is applied to the parts of the instrument, shielding, instruments, etc., can solve the problems of pollution, large power consumption, short service life, etc., and achieve low cost of use, simple manufacturing process and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

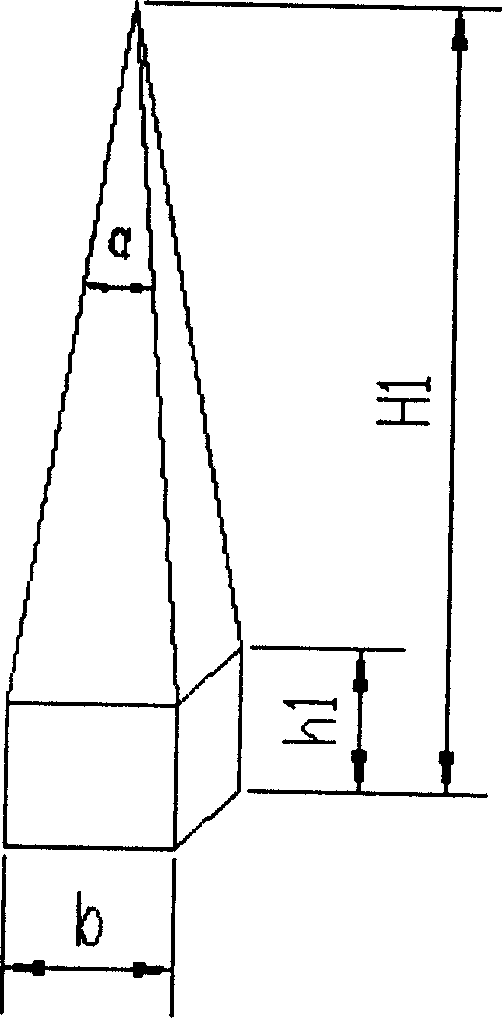

[0020] Such as figure 1 As shown, take non-woven fabric as carrier; mix aluminum-magnesium composite powder (magnesium oxide powder can also be used), water-soluble plasticizer, binder such as modified polyvinyl alcohol and appropriate amount of water, mix well, and then coat On the non-woven fabric, let it stand for a while; then mix the binder, carbon black and an appropriate amount of water, stir evenly, and coat it on the non-woven fabric after it has been left, and then let it stand for a while; The size of the pyramid unit body is mechanically indented, and then folded according to the indentation marks, bonded with an adhesive, and made into the shape of the pyramid unit body, and dried and shaped. As long as one surface is coated and the surface is the outer layer, the pyramid unit body is made. Strengthen the structural performance of the non-woven fabric, flame retardant, make the non-woven fabric foldable, elastic, and able to absorb waves.

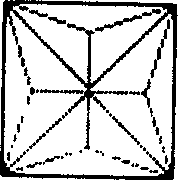

[0021] Such as figure 2 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com