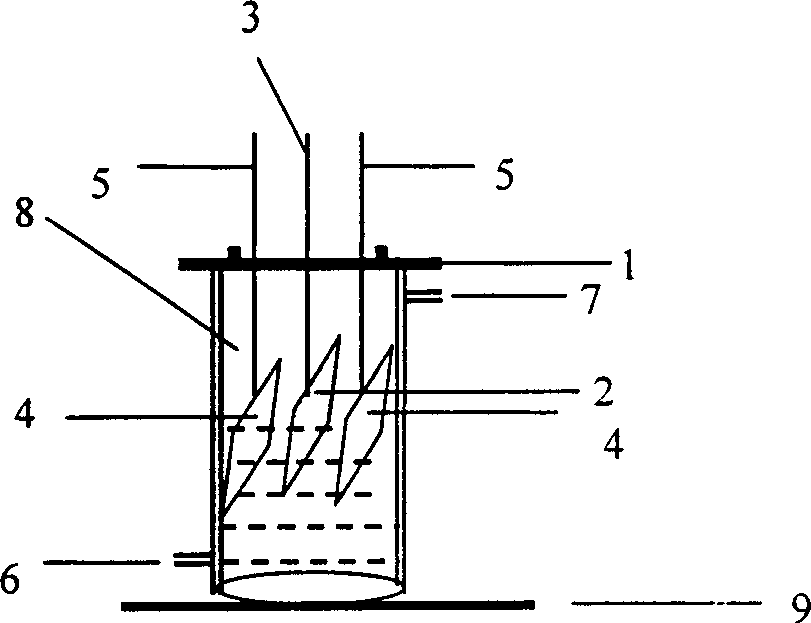

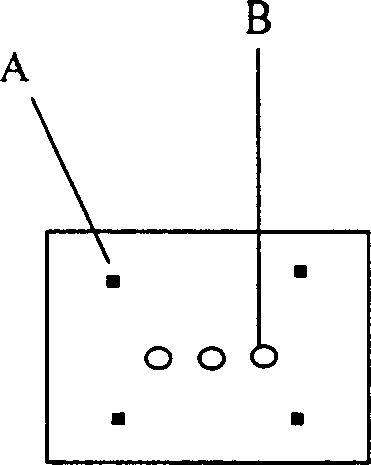

Porous aluminium oxide template preparing method and its apparatus

A porous alumina and template technology, applied in anodizing and other directions, can solve the problems of inconvenient height adjustment of aluminum sheets and platinum sheets, slippage of the electrolytic cell cover, expensive materials, etc., achieving good results, simple replacement of parts, and material easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

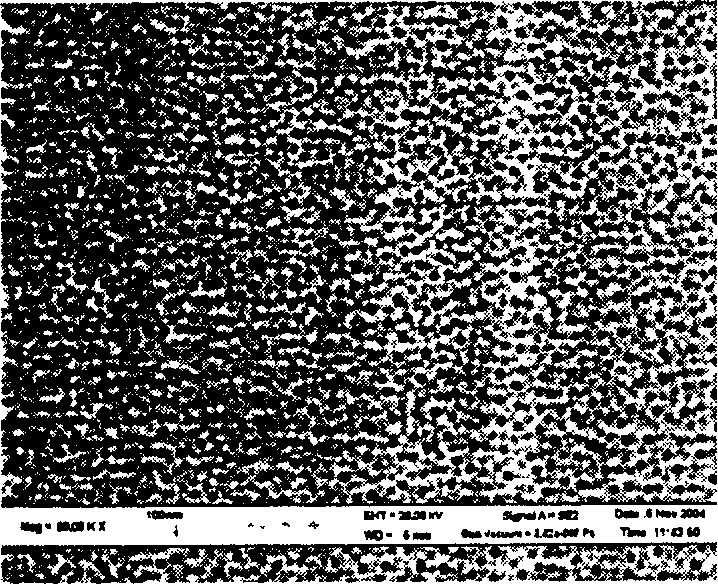

Embodiment 1

[0026] 1) Wipe the aluminum foil clean with filter paper, and cut it into small pieces about the same size as the platinum piece. The platinum sheet is 3cm×4.5cm in size. Put 115ml H 3 PO 4 , 80ml glycerol and 0.5ml H 2 SO 4 Polish in the solvent of the mixture for 3 to 5 minutes. Polishing uses almost the same setup for anodizing, just swapping the jacketed electrolytic cell for a 250ml beaker. Then the whole device is heated in a water bath above 70°C, and rinsed with deionized water after polishing.

[0027] 2) Put the polished aluminum foil into the electrolytic cell and pour in the electrolytic solution. The electrolytic solution is oxalic acid with a concentration of 0.2M, and the electrolytic cell is kept at a constant temperature at room temperature by running tap water. Connect the circuit and turn on the power to keep the circuit constant at 45V. At the same time, turn on the magnetic stirrer and oxidize for 65 minutes.

[0028] 3) Soak the oxidized aluminum ...

Embodiment 3

[0031] 1) Wipe the aluminum foil clean with filter paper, and cut it into small pieces about the same size as the platinum piece. The platinum sheet is 3cm×4.5cm in size. Put 144ml H 3 PO 4 , 120ml glycerol and 0.6ml H 2 SO 4 The mixture was polished in solvent for 4 minutes. Polishing uses almost the same setup for anodizing, just swapping the jacketed electrolytic cell for a 250ml beaker. Then the whole device is heated in a water bath above 80°C, and rinsed with deionized water after polishing.

[0032] 2) Put the polished aluminum foil into the electrolytic cell and pour in the electrolytic solution. The electrolytic solution is phosphoric acid with a concentration of 0.25M, and the electrolytic cell is kept at a constant temperature at room temperature by running tap water. Connect the circuit, turn on the power supply, and keep the circuit constant at 50V. At the same time, turn on the magnetic stirrer and oxidize for 30 minutes.

[0033] 3) Soak the oxidized alu...

Embodiment 4

[0035] 1) Wipe the aluminum foil clean with filter paper, and cut it into small pieces about the same size as the platinum piece. The platinum sheet is 3cm×4.5cm in size. Put 160ml H 3 PO 4 , 80ml glycerol and 0.56ml H 2 SO 4 The mixture was polished in a solvent for 3 minutes. Polishing uses almost the same setup for anodizing, just swapping the jacketed electrolytic cell for a 250ml beaker. Then the whole device is heated in a water bath above 85°C, and rinsed with deionized water after polishing.

[0036] 2) Put the polished aluminum foil into the electrolytic cell and pour in the electrolytic solution. The electrolytic solution is phosphoric acid with a concentration of 0.1M, and the electrolytic cell is kept at a constant temperature at room temperature by running tap water. Connect the circuit well, turn on the power supply, and keep the circuit constant at 48V. At the same time, turn on the magnetic stirrer and oxidize for 90 minutes.

[0037] 3) Soak the oxidiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com