Intelligent concrete test block and its producing and use

A concrete test block, intelligent technology, applied in the direction of clay preparation device, test sample preparation, manufacturing tools, etc., can solve problems such as unstable resistivity, carbon fiber cannot be dispersed, test block conductivity decline, etc., to achieve rapid growth , the test data is stable and the effect of repeatability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

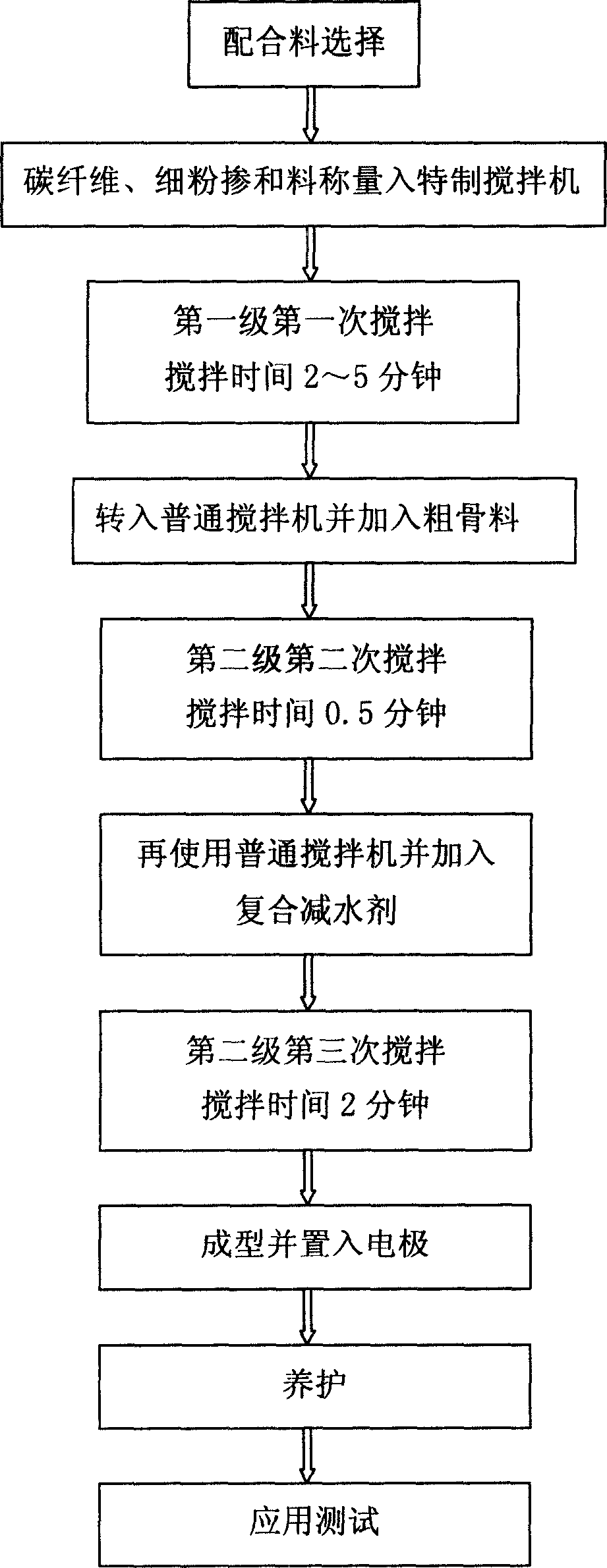

[0040] In conjunction with accompanying drawing and chart, embodiment of the present invention is as follows:

[0041] One, the intelligent concrete test block of the present invention.

[0042] 1. The choice of ingredients. First select the carbon fiber raw material. In this embodiment, the PAN-based carbon fiber produced by a certain company is selected. Its physical and chemical properties can be seen from the physical and chemical properties table in Figure 2. The fine powder admixture is composed of 1% cement, 0.12-0.145% fly ash, and 0.12%-0.199% slag or silica fume. Among them, this embodiment adopts two different admixture ratio schemes, slag It is the granulated blast furnace slag of a certain Iron and Steel Group Co., Ltd. After drying and ball milling, the fineness of ball milling is 0.08mm sieve, the sieve allowance is 10.5%, and the loose bulk density after grinding is 1.41g / cm 3 , and its chemical composition is shown in Figure 3. During the proportioning proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com