Concentrated solution for washing and preparation method thereof

A concentrated liquid and sulfate technology, which is applied in the direction of detergent materials, detergent compositions, chemical instruments and methods, etc., can solve the problems of inconvenient storage and processing, low content of active substances, etc., and achieve convenient storage and processing, strong Pearl effect, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

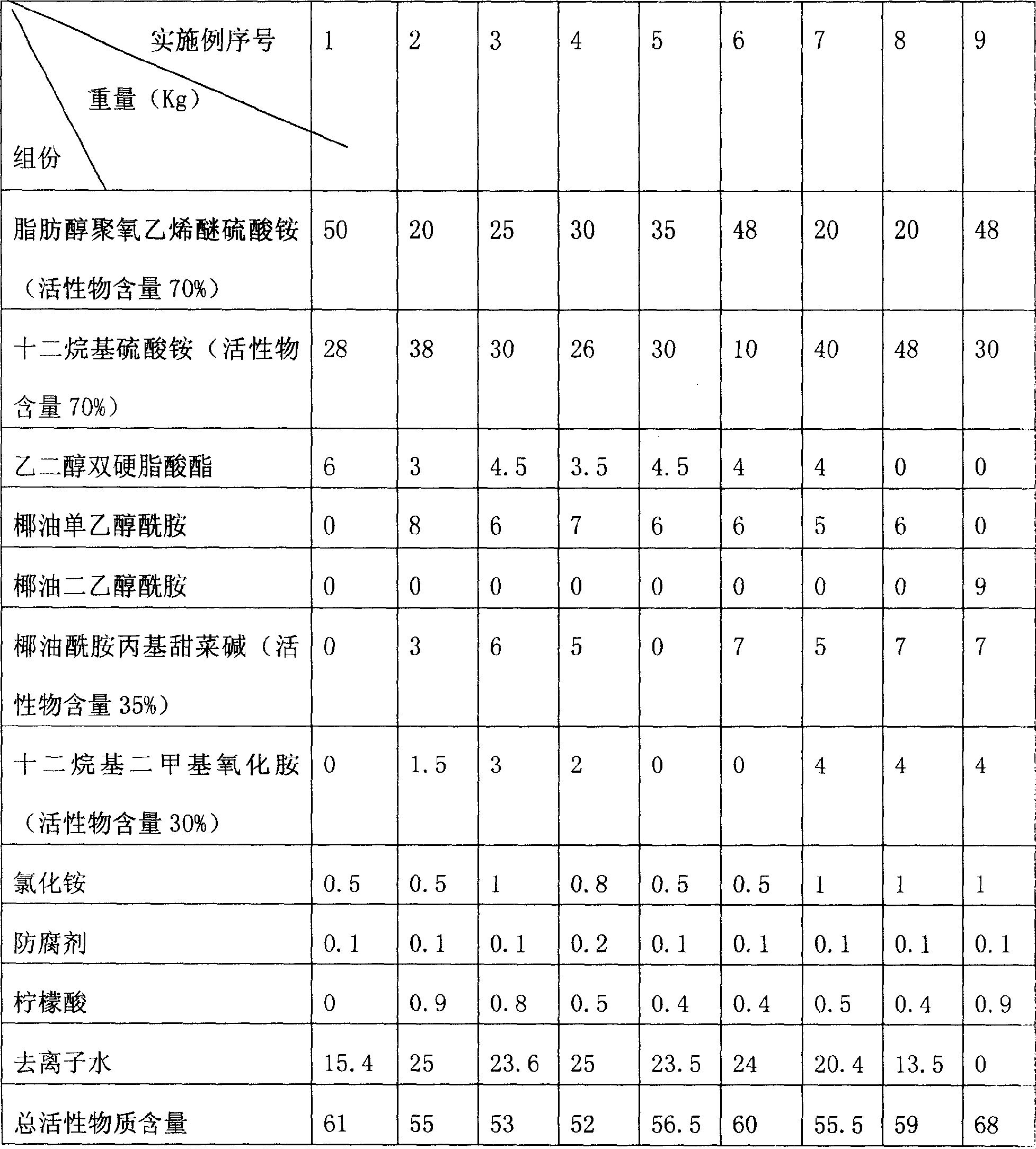

Examples

Embodiment 1

[0019] The preparation method of described washing concentrate is as follows:

[0020] First heat the water to 85°C, and keep the temperature not lower than 85°C, stir and dissolve ethylene glycol stearate and coconut oil monoethanolamide, then add 10Kg fatty alcohol polyoxyethylene ether ammonium sulfate, Stir for 5-15 minutes, then control the temperature between 50°C-60°C, let the above mixture stand for 1-2 hours, add ammonium chloride and stir for 5-10 minutes, add the remaining 40Kg between 45°C-50°C Fatty alcohol polyoxyethylene ether ammonium sulfate and ammonium lauryl sulfate, cocamidopropyl betaine, lauryl dimethylamine oxide, preservative, just stir well.

[0021] The appearance of the concentrated washing liquid is pearly milky white, crystal clear, has a strong pearlescent effect, and is a thick paste liquid. The concentrated washing solution can be directly diluted with water to prepare a washing solution. Recommended dosage The washing concentrate accounts fo...

Embodiment 2

[0023] The preparation method of described washing concentrate is as follows:

[0024] Firstly, the water is heated to 90° C., and the rest of the steps are the same as those described in Example 1. In addition, citric acid is added to adjust the pH value to 6-7 before adding the preservative. The prepared washing concentrated liquid is pearly milky white in appearance, crystal clear, has strong pearlescent effect, and is a thick paste liquid. Its method of use is the same as that described in Example 1.

Embodiment 3

[0026] The preparation method of described washing concentrate is as follows:

[0027] Firstly, the water is heated to 100° C., and the rest of the steps are the same as those described in Example 2. The prepared washing concentrated liquid is pearly milky white in appearance, crystal clear, has strong pearlescent effect, and is a thick paste liquid. Its method of use is the same as that described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com