Welding head with high efficiency and long life

A long-life, soldering iron tip technology, applied in the direction of soldering iron, metal processing equipment, manufacturing tools, etc., can solve the problems of short service life, poor heat conduction effect, etc., and achieve the effect of increased life, good heat conduction effect, and improved heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

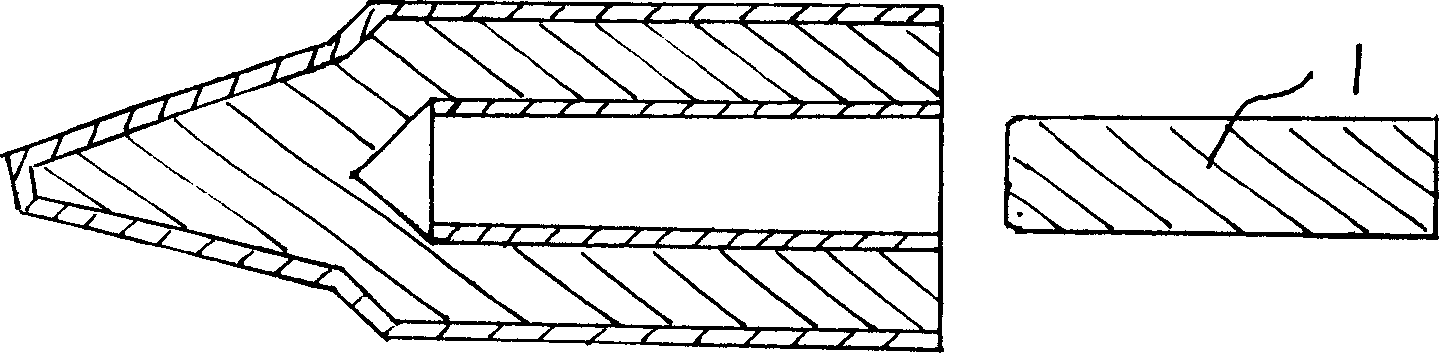

Embodiment 1

[0018] Such as figure 2 As shown, there is a heating core 1, and the heating core 1 is cylindrical or square column-shaped, and its front end is a heating working end 2, and its back is a heating cylinder 3. The outside of the heating core 1 is connected to the iron protective cover 4 with a high-temperature-resistant adhesive (such as sodium silicate—water glass), and the heating working end 2 and the heating cylinder 3 behind it can be integrated without a mechanical interface. structure, the size of the heating end 2 gradually decreases from back to front, that is, the cross-sectional area of the heating working end 2 is smaller than the cross-sectional area of the heating cylinder 3, and a variety of ceramic heating materials can be used to make the required heating core, such as Molybdenum disilicide or other ceramic heating materials such as silicon carbide, lanthanum chromate, etc. The electrical properties of the heating material can fully meet the requirements, ...

Embodiment 2

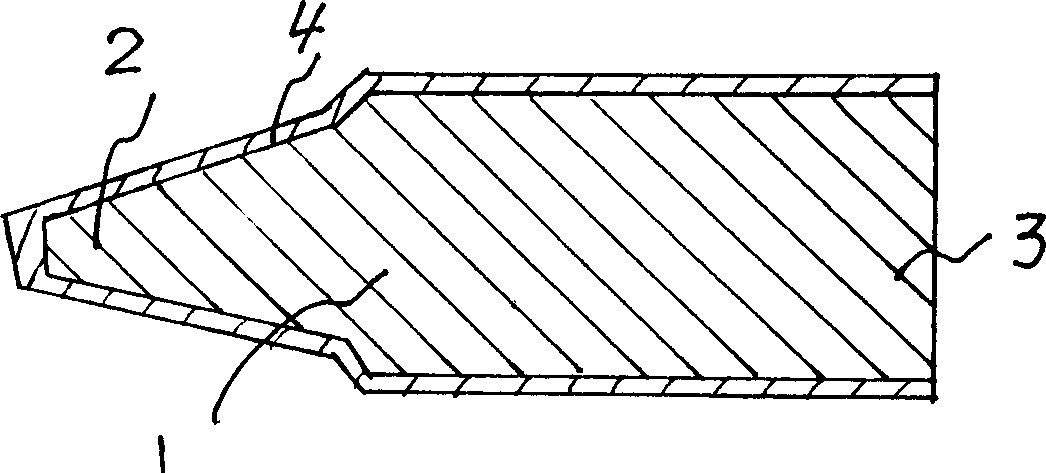

[0020] As shown in Figures 3 and 4: there is a heating core 1, the heating core 1 is cylindrical, the front end is a heating working end 2, and the back is a heating cylinder 3. The outer surface of the heating core 1 is sleeved with a high-temperature resistant adhesive (such as sodium silicate—water glass) to cover the iron protective cover 4, and the heating working end 2 and the heating cylinder 3 behind it can be without a mechanical interface. The integral structure can also be connected separately. The part of the heating end 2 is in the shape of a truncated cone whose size gradually decreases from back to front, that is, the cross-sectional area of the heating working end 2 is smaller than that of the heating cylinder 3 . To make the heating core 1, first sinter the ceramic substrate with a similar shape or cone shape to the working part of the soldering iron tip. The substrate can be made of alumina, and the heating wire 6 is wound on the substrate. The wire part ca...

Embodiment 3

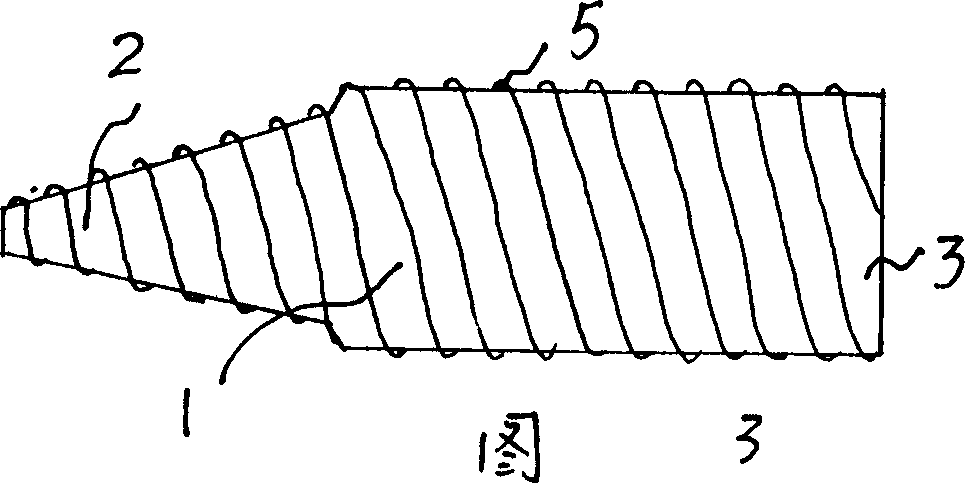

[0022] Such as Figure 5 As shown: Others are as in Embodiment 1 and 2, except that the heating working end 2 at the front end of the heating core 1 is cylindrical, and its diameter is smaller than the heating cylinder 3 behind the heating core 1, that is, the cross-sectional area of the heating working end 2 is smaller than the heating column The cross-sectional area of body 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com