Iron base rare earth high chromium steel impellor blade

An impeller blade, rare earth and high chromium technology, applied in liquid fuel engines, mechanical equipment, pumps, etc., can solve the problems of erosion resistance, poor wear resistance, large shutdown loss, and short service life, and achieve wear resistance. Excellent, reducing the number of replacements, the effect of excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

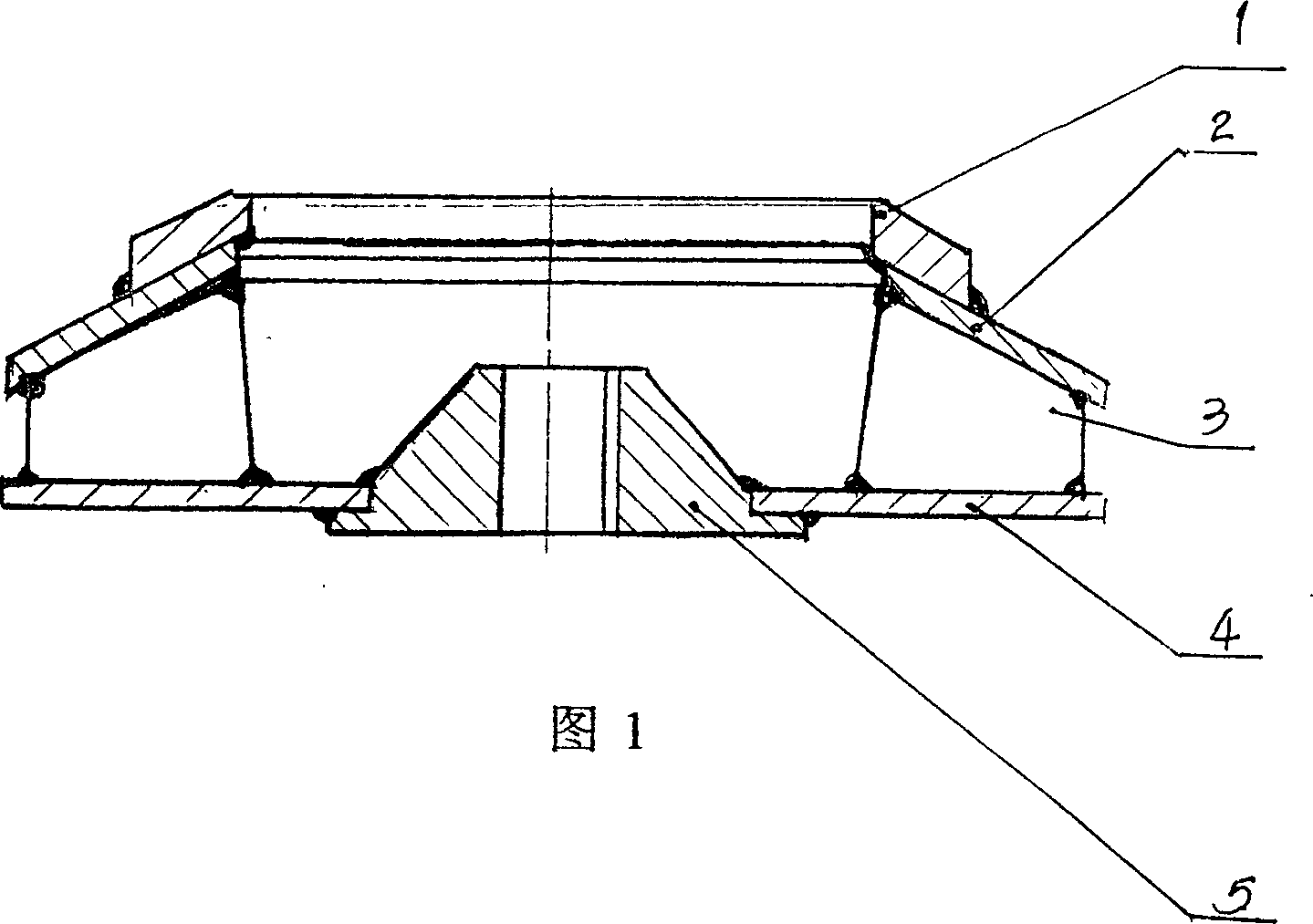

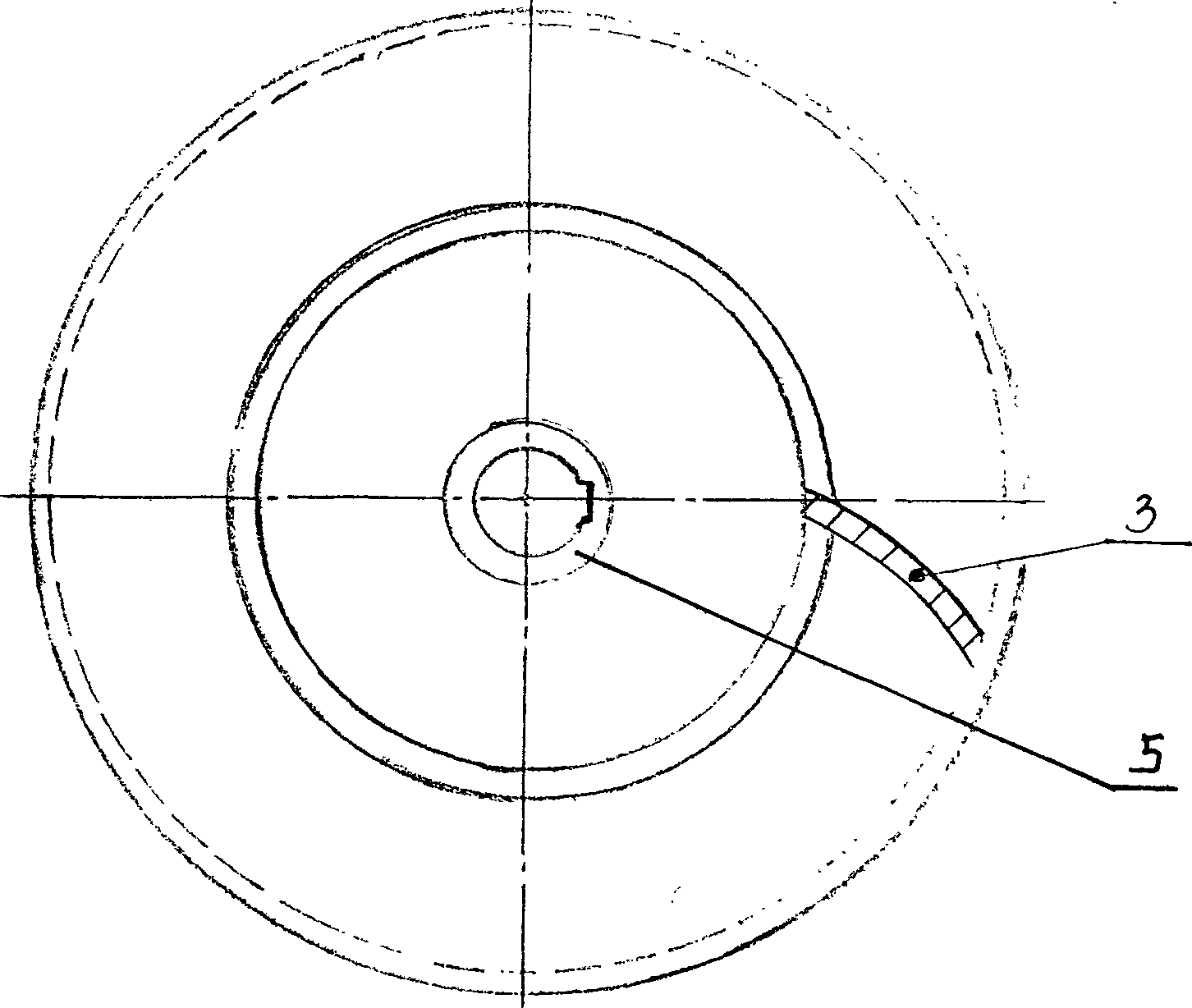

[0015] The present invention includes a front disk reinforcement ring 1, a front disk 2, blades 3, a rear disk 4, and a hub 5. The impeller blade 3 is a dual-phase structure in which austenite, ferrite, and carbide coexist in the as-cast state, and its composition The percentage by weight is: C: 0.3%, Cr: 17-26%, Ni: 2-6%, Si: 0.40-1.0%, Mn: 0.40-1.0%, S≤0.04%, P≤0.04%, the present invention The impeller blade adopts a new steel type, which does not contain molybdenum and vanadium in the composition, so that the alloy of the impeller blade obtains a dual-phase structure in which austenite, ferrite, and carbide coexist. # Rare earth ferrosilicon alloy processing, the rest is iron and impurities usually formed under smelting conditions. It has good welding performance, especially after the micro-chemical treatment of rare earth, the melting point of manganese sulfide without adding rare earth is 800°C, and the melting point of rare earth sulfide after adding rare earth is increa...

Embodiment 2

[0017] The present invention includes a front disk reinforcement ring 1, a front disk 2, blades 3, a rear disk 4, and a hub 5. The impeller blade 3 is a dual-phase structure in which austenite, ferrite, and carbide coexist in the as-cast state, and its composition The percentage by weight is: C: 0.35%, Cr: 18-24%, Ni: 3-4%, Si: 0.4-0.70%, Mn: 0.40-0.70%, S<=0.025%, P<=0.025%

[0018] Add 0.021-0.3% Baotou 1 to the ladle when it comes out of the furnace # Rare earth ferrosilicon alloy processing, the rest is iron and impurities usually formed under smelting conditions.

[0019] The smelting is smelting in a non-iron core, non-vacuum intermediate frequency induction furnace, using high-quality furnace materials and alloy materials, low-temperature desulfurization, and a slag ratio of 4% during smelting; high-temperature deoxidation during molten steel refining, using CaSi deoxidizer, and diffusion deoxidation with 0.1 % calcium silicate powder, 0.1% calcium silicate block for p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap