External electrode fluorescent lamp tube with high light optical effect low operating voltage and process for making same

A technology of working voltage and fluorescent tubes, applied in the manufacture of electrode systems, manufacture of discharge tubes/lamps, discharge lamps, etc., to achieve high luminous efficiency, prolong life, and improve luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

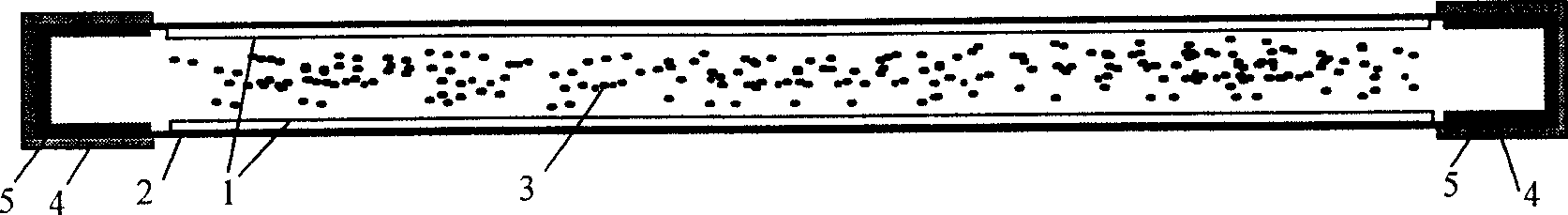

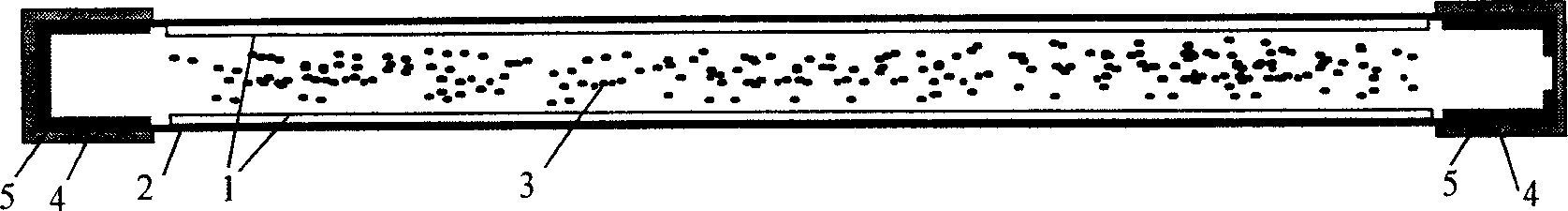

[0019] A fluorescent tube with high luminous efficiency and low working voltage external electrode that can be used as a liquid crystal backlight source or lighting. It includes a lamp tube glass bulb 2 with both ends closed. External electrodes 4 are arranged on the outer surfaces of both ends of the tube glass bulb 2, discharge gas 3 is filled in the lamp tube glass bulb 2, and a high secondary electron emission material dielectric layer is arranged on the inner surfaces of both ends of the lamp tube glass bulb 2 5. The above-mentioned high secondary electron emission material dielectric layer 5 is a magnesium oxide layer, an aluminum oxide layer or a magnesium aluminate layer. The high secondary electron emission material dielectric layer 5 can also be other high secondary electron emission materials. The above-mentioned lamp tube glass bulb 2 Can be straight, curved, spiral or other shapes.

Embodiment 2

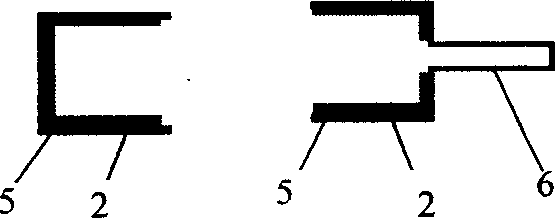

[0021] A preparation process for manufacturing the above-mentioned high-luminous-efficiency low-voltage external-electrode fluorescent lamp tube: take the cleaned and dried lamp tube glass bulb with openings at both ends and two covers that can be sealed to the opening of the lamp tube glass bulb, and place one of them An exhaust pipe 6 is arranged on the cover, a high secondary electron emission material medium layer is set on the inner surfaces of the two covers, a high secondary electron emission material medium layer 5 is prepared on the inner surface of an open end of the lamp tube glass bulb, and then a high secondary electron emission material medium layer 5 is prepared on the lamp tube glass A phosphor layer 1 is arranged on the inner wall of the shell, and a medium layer of high secondary electron emission material is prepared on the inner surface of the other open end of the glass bulb of the lamp tube, and the covers are respectively sealed to both ends of the glass b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com