Vertical sieve plate and its application method in the separation system of ethyl acetate esterification

A technology of ethyl acetate and vertical sieve plates, applied in chemical instruments and methods, preparation of carboxylic acid esters, preparation of organic compounds, etc., can solve the problems of easy fouling and blockage of sieve holes, high mass transfer efficiency and mass transfer space Problems such as low utilization rate and narrow operating flexibility can achieve the effect of increasing the crude ester content at the top of the tower, reducing energy consumption and stabilizing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

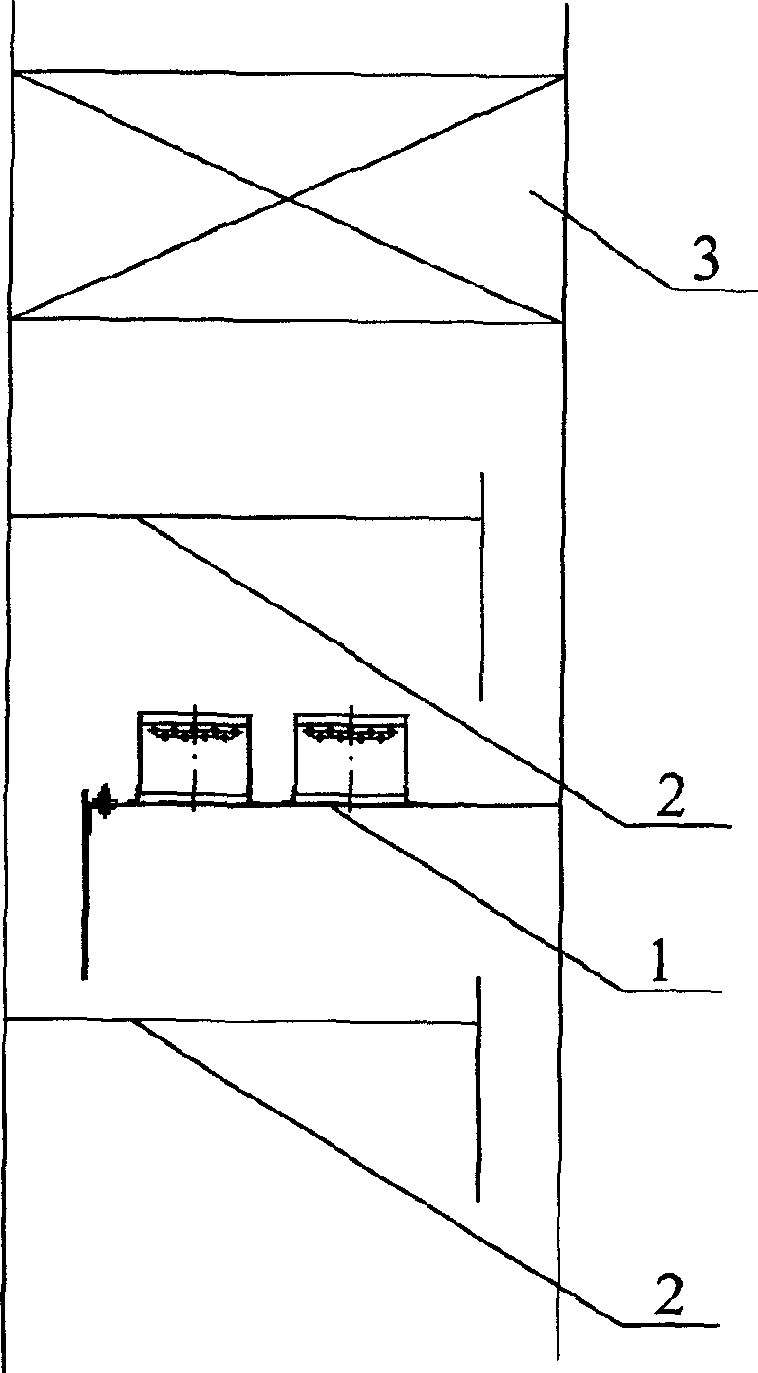

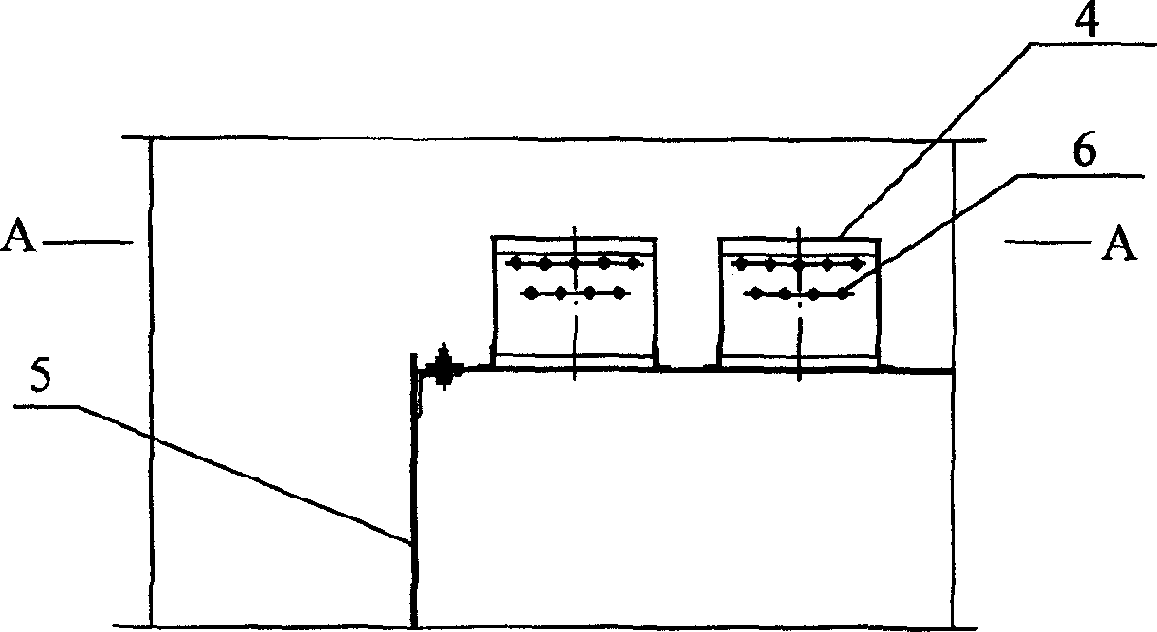

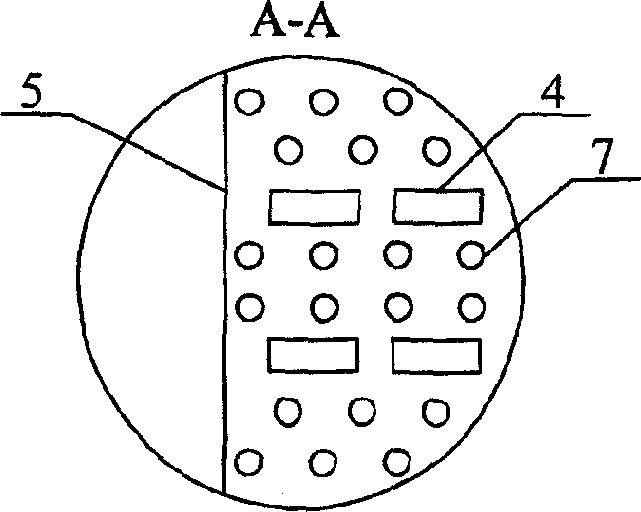

Image

Examples

Embodiment

[0016] The raw material feed components and proportioning ratio (weight) are: acidity (calculated by acetic acid) 55.0%, alcohol (calculated by ethanol) 40%, moisture 5%. According to the above requirements, select 316L stainless steel with a suitable thickness and a vertical sieve plate with a long hood. In the embodiment, 316L common sieve plate and 304 and 316L metal structured packing are used.

[0017] In the embodiment of the present invention, a stainless steel sheet is used to make the vertical sieve plate, which is not a limitation of the present invention, and the protection of the present invention shall be subject to the claims.

[0018]

Column type

Original random ceramic packing

tower

Original improved structured pottery

Porcelain packed tower

Examples described are equipped with vertical

sieve plate mixed structure tower

Tower top temperature (°C)

72.0±1.0

71.6±1.0

70.6±0.5

Tow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com