Liquid curing agent for making road and its production process

A manufacturing method and curing agent technology, applied in chemical instruments and methods, applications, construction, etc., can solve the problems of large cement and lime consumption, excessive transportation costs, and a large amount of sand and gravel, so as to reduce road construction costs, reduce consumption, The effect of thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

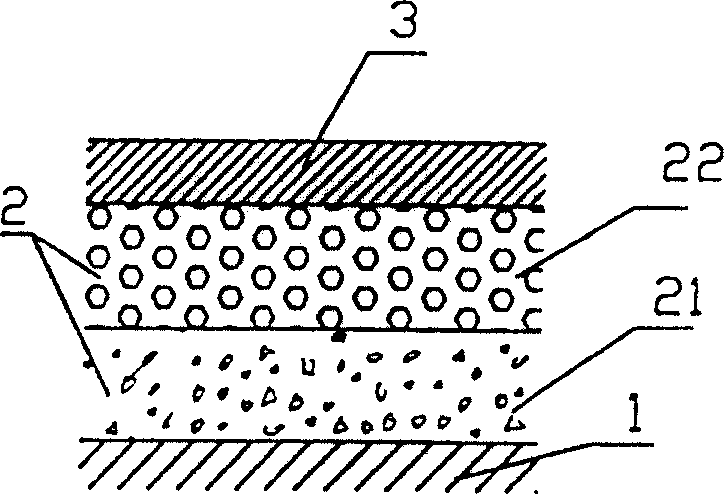

[0032] figure 1 Among them, the road built in the prior art needs to be paved with 4 layers. The bottom layer is a road bed 1, on which is a subbase 21, then an upper base 22, and finally an asphalt wear course 3. The base layer 21 is combined with the upper layer 22 to form the base layer 2 .

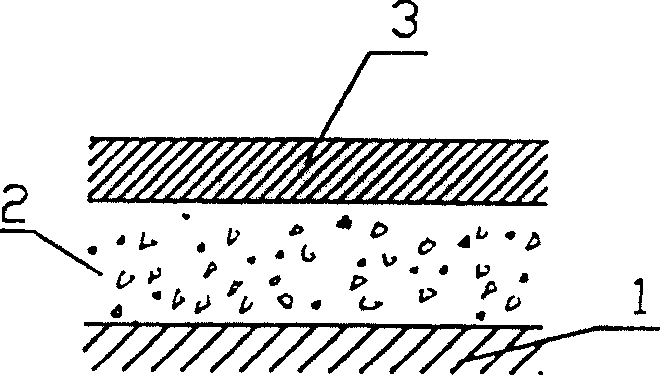

[0033] figure 2 Among them, the road construction method described in the present invention is the same as the prior art. First, the road bed 1 is rolled to the specified requirements with a road roller, and then the base layer 2 is paved on the road bed 1. Finally, it is the same as the prior art. , Laying asphalt wearing layer 3 on the base layer 2.

[0034] The base layer 2 is specifically formed by mixing soil, sand, solid curing agent and liquid curing agent and rolling them.

[0035] The weight ratio of soil, sandstone, solid curing agent and liquid curing agent is:

[0036] Soil: sand: liquid curing agent: solid curing agent = 1: 0.2-0.4: 0.001-0.015: 0.05-0.25.

[0037] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com