Diode with improved energy impulse rating

A technology of grades and electrode layers, used in diodes, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problems of complex manufacturing and expensive multi-layer structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

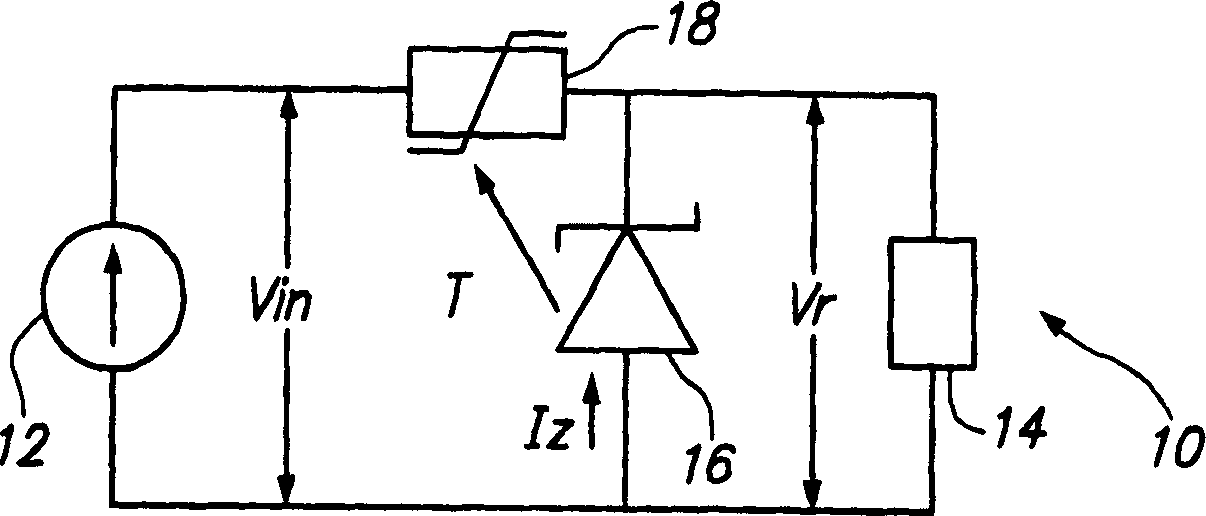

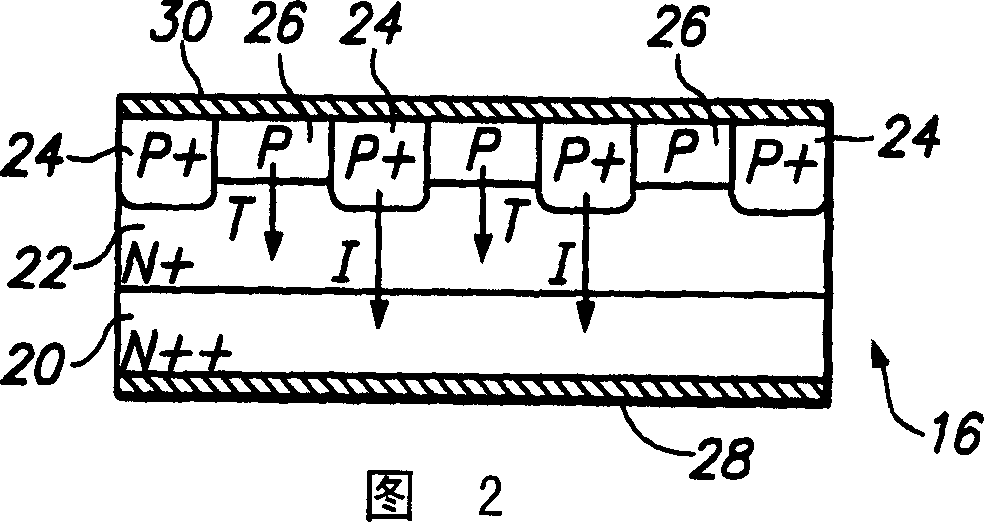

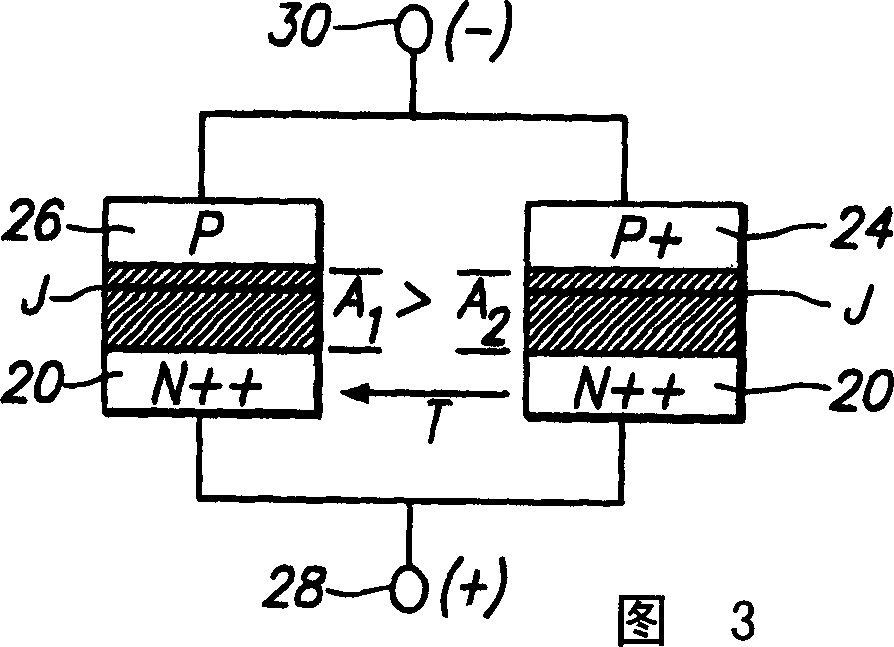

[0031] We have discovered diode chip arrangements and structures that increase the temperature withstand capability of the diode in response to overvoltage energy pulses. The diode includes regions of higher resistivity (eg, p+ regions) created by epitaxial growth or impurity diffusion. Heavier doping is provided in the cell region of the diode (eg p++) to ensure Zener tunneling and / or impact ionization at reverse bias voltage breakdown levels. As the chip temperature increases, the lighter doped (p+) regions reach the intrinsic (ohmic) transition temperature before the more heavily doped (p++) cell regions, whereby a concentrated anode-cathode current flows through These lighter doped regions of the chip. This diversion of current increases the temperature in the more lightly doped regions, thereby spreading the temperature more uniformly in the chip and affecting the ohmic current-voltage characteristics of the more lightly doped regions. The ratio of intrinsic / zener volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com