Method of mfg. sealing strip for door and window

A manufacturing method and technology for sealing strips, which are applied in the field of building materials, can solve problems such as failure to meet sealing requirements, easy rupture of sealing strips, and short service life, and achieve the effects of stable performance, good sound insulation effect and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

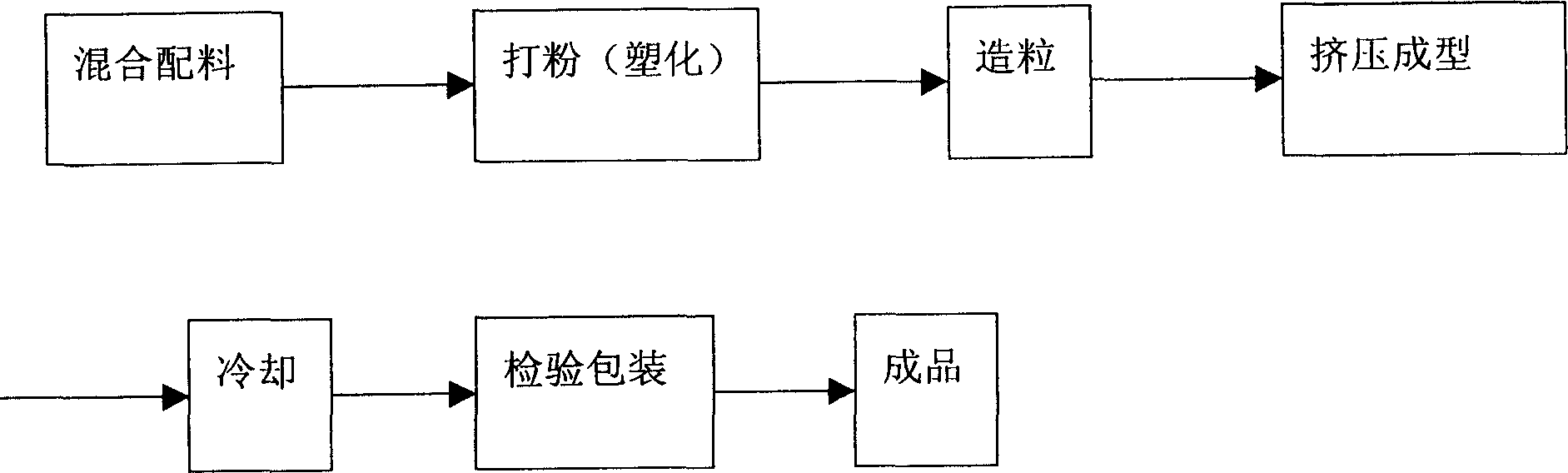

Method used

Image

Examples

Embodiment 1

[0014] In this embodiment, PVC: 40, dibutyl: 40, lead stearate: 0.4, barium stearate: 0.4, di-salt: 0.6, tri-salt: 0.5, stearic acid: 0.25, paraffin wax: 0.25, Titanium dioxide: 0.3, AC (foaming agent): 1.5, stone powder: 5, carbon black: 0.4 Put in the mixer and mix evenly; perform powdering, plasticize and enter the granulator for granulation, the granulation temperature is: 120 °C; Put the above-made plastic pellets into the extruder for extrusion molding, select different mold cavities according to different specifications of the product, and the extrusion temperature is: 120°C; then put the formed semi-finished products in the water tank for cooling, The residence time in the water tank is very short, the specific time depends on the specifications of the product, and the cooling temperature is: 15°C. Final inspection, finished product packaging and leaving the factory.

[0015] The sealing strip manufactured by adopting the formula ratio in this embodiment 1 has good se...

Embodiment 2

[0017] In this embodiment, PVC: 49, dibutyl: 37.5, lead stearate: 0.5, barium stearate: 0.5, di-salt: 0.8, tri-salt: 0.75, stearic acid: 0.4, paraffin wax: 0.4, Titanium dioxide: 0.4, AC (foaming agent): 1.8, stone powder: 8, carbon black: 0.45 Put in the mixer and mix evenly; perform powdering, plasticize and enter the granulator for granulation, the granulation temperature is: 140 °C; Put the above-made plastic pellets into the extruder for extrusion molding, select different mold cavities according to different specifications of the product, and the extrusion temperature is: 155°C; then enter the formed semi-finished product into the water tank for cooling, and in the water tank The residence time is very short, and the specific time depends on the specifications of the product. The cooling temperature is: 23°C. Final inspection, finished product packaging and leaving the factory.

[0018] The sealing strip produced by adopting the formula ratio in the second embodiment al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com