Method and equipment for producing minor diameter magnesium alloy welding wire by arranging temperature control system in extrusion chamber

A temperature control system and extrusion cylinder technology, applied in metal extrusion control equipment, welding equipment, metal processing equipment, etc., can solve the problems of variable temperature, difficulty, forming difficulty, etc. , The effect of good product quality and high degree of diameter consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

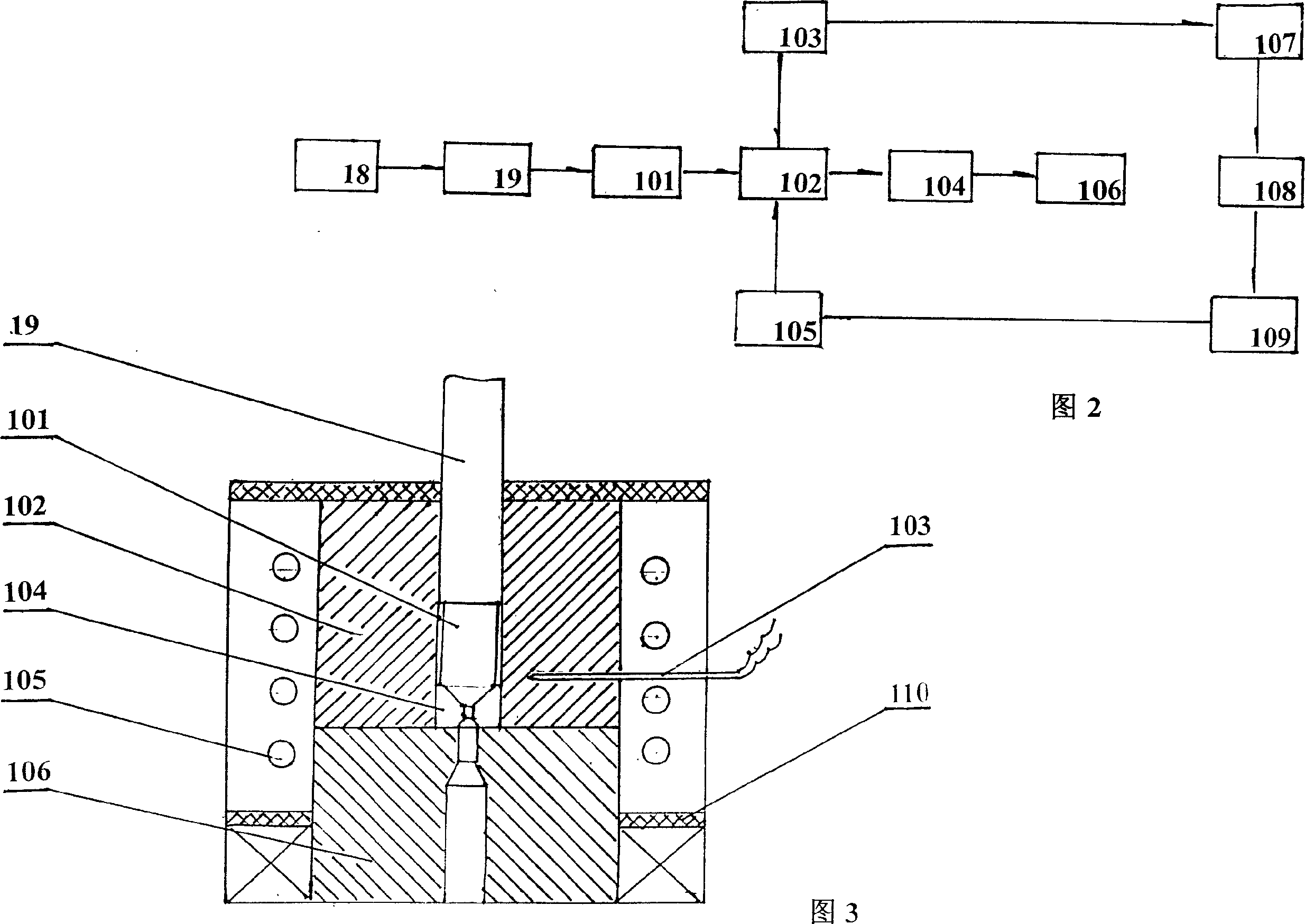

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

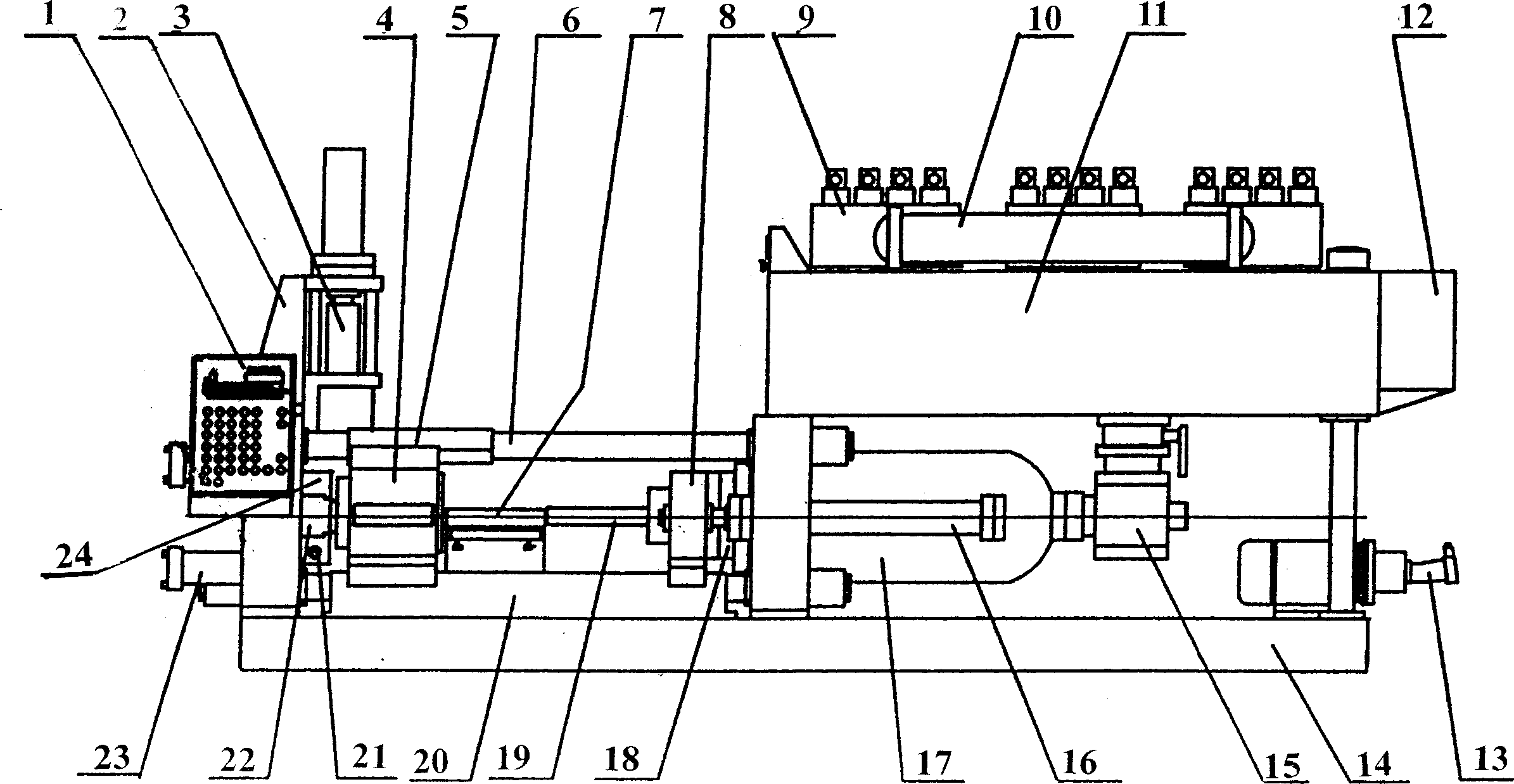

[0011] The extrusion machine is the main equipment for welding wire production, such as figure 1 As shown, it mainly consists of the following parts, as the equipment body and supporting machine base 14, front beam 2, movable beam and ingot holder 4, guide rail 20, upper guide rail 5, tension column 6, piston bracket 8; power supply related The equipment includes an electric control instrument cabinet 12, a motor and an oil pump 13; the hydraulic system 9 with oil as the working fluid, and the related components include the oil tank 11, the oil cooler 10 with water as the cooling fluid, the oil filling valve 15, the quick cylinder 16, and the main oil cylinder 17, mold changing oil cylinder 21, locking oil cylinder 23; operation device has operation box 1, plunger 18, extruding rod 19; auxiliary operation part has shearing mechanism 3, for spindle devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com