Micro interior cavity dimension measuring apparatus and method based on double optical fiber coupling

A measuring device and inner cavity technology, which is applied in the field of measuring the size of tiny inner cavities, can solve problems such as inability to complete measurement work, weak image signals, and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

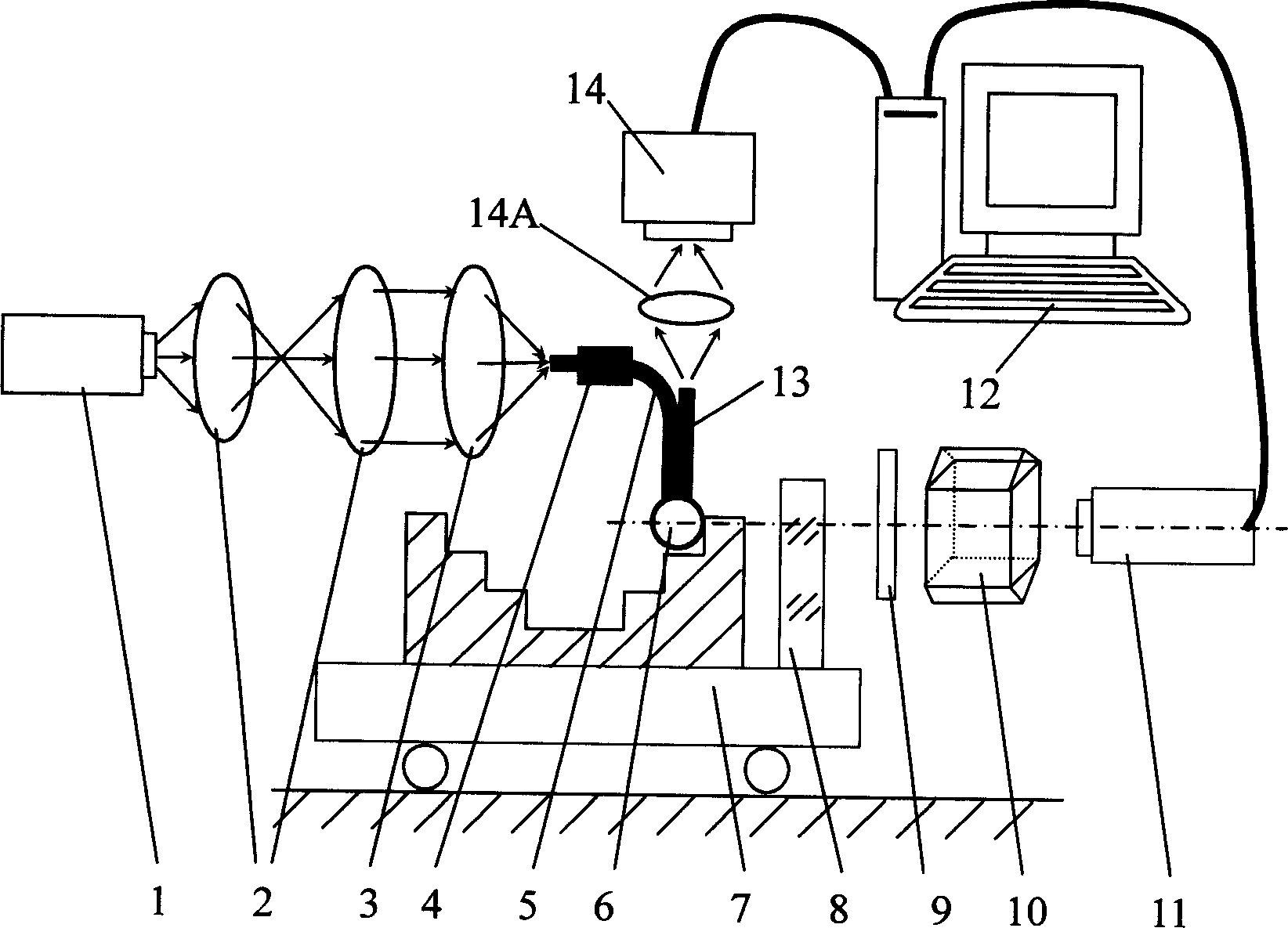

[0035] refer to figure 1 To Fig. 4, the tiny inner cavity size measuring device based on dual-fiber coupling in the present embodiment includes a laser 1, a beam expander collimating mirror 2, a fiber coupling lens 3, a fixed body 4, an incident optical fiber 5, a coupler 6, and a working Table 7, reflective flat crystal 8, λ / 4 wave plate 9, polarizing beam splitter 10, dual-frequency laser 11, computer 12, outgoing optical fiber 13 and CCD camera 14;

[0036] The laser 1, the beam expander collimator 2, the fiber coupling lens 3, and the fixed body 4 together constitute a laser coupling unit, wherein the laser 1, the beam expander collimator 2, the fiber coupling lens 3 and one end of the incident fiber 5 are coaxial, The fixed block 4 fixes the incident optical fiber 5;

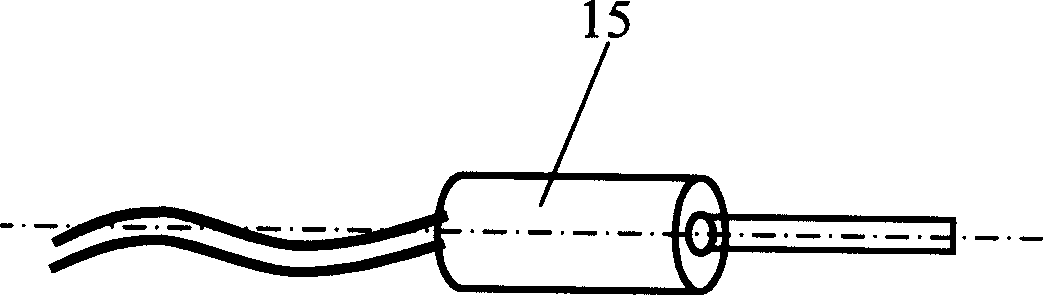

[0037] The incident optical fiber 5, the coupler 6 and the outgoing optical fiber 13 together constitute a dual-fiber coupling unit; wherein, the incident optical fiber 5 is in the shape of a right-angle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com